D type photonic crystal fiber refractive index sensor using double-loss-peak detection

A technology of photonic crystal fiber and refractive index sensor, which is applied in the direction of cladding fiber, optical waveguide light guide, optics, etc., can solve the problem of low single-peak detection accuracy and recognition, loss peak detection spectral range is not optional, and detection methods are not perfect, etc. problems, to achieve the effect of good operation convenience, accurate and efficient detection means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

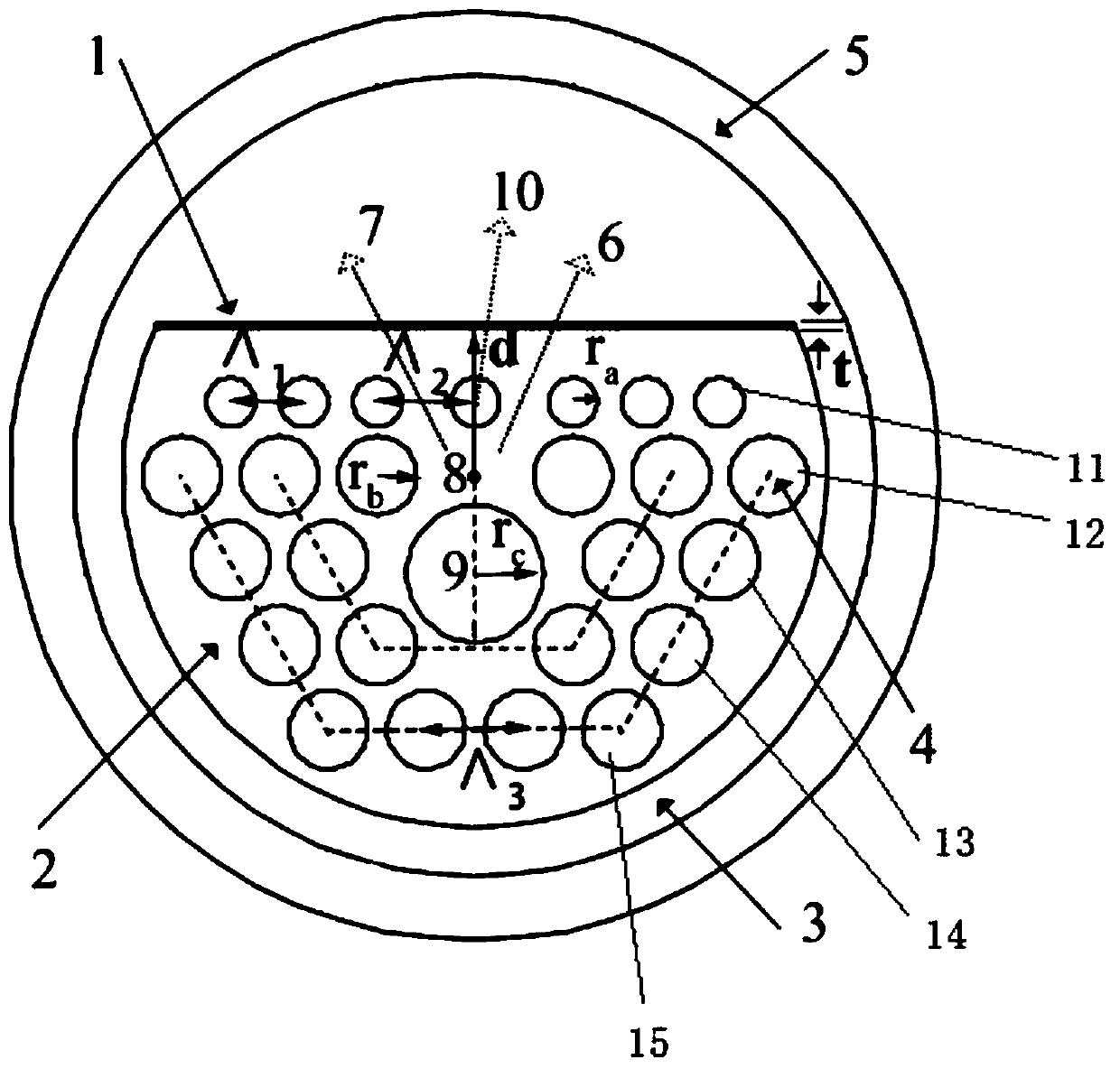

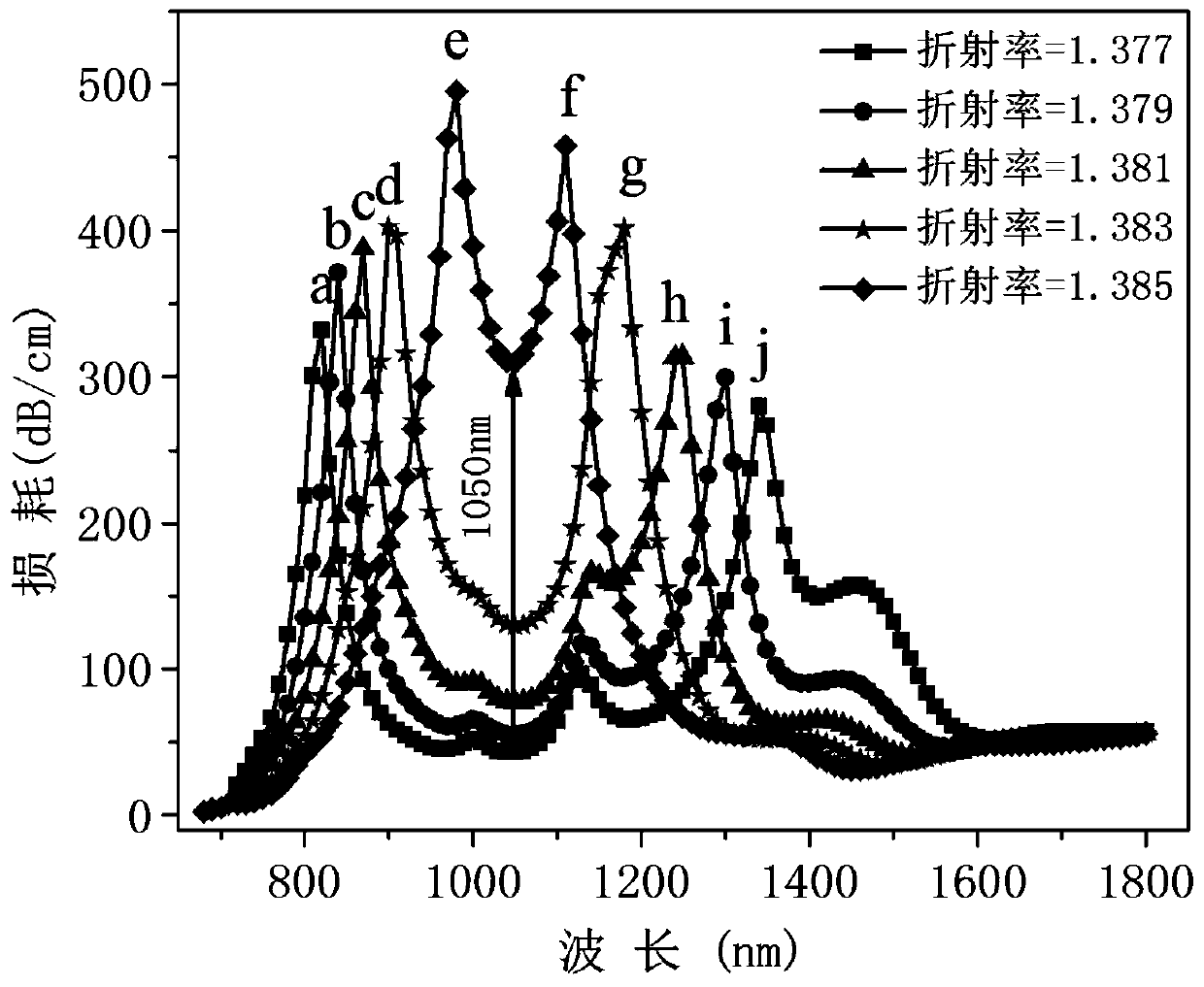

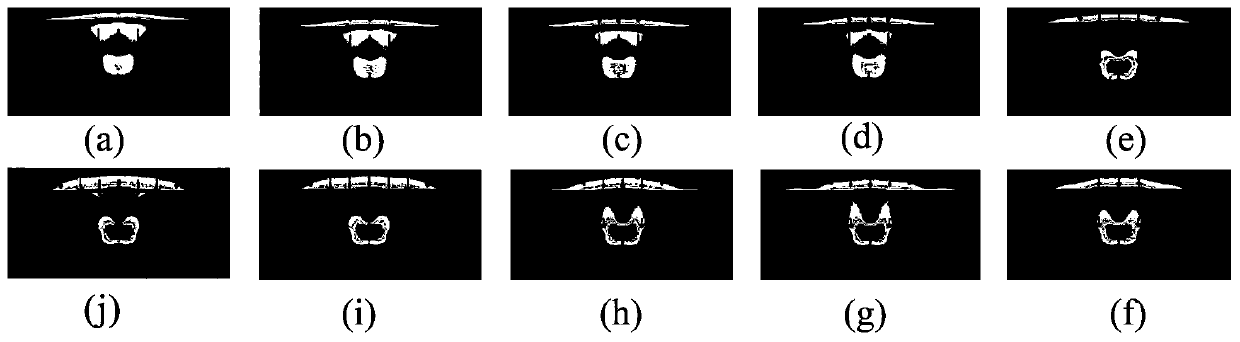

[0057] figure 1 It is the end face structure diagram of the D-type photonic crystal fiber refractive index sensor capable of double loss peak detection according to the present invention. exist figure 1 In the process, a layer of gold film 1 is deposited on the polished surface of the optical fiber. The thickness of the gold film is 40nm, which is used as the induction material for the surface plasmon resonance effect; next to the gold film is the liquid analyte 3, and the sensor is used It is enough to completely immerse the optical fiber in the liquid 3 of the analyte to be measured; the outermost layer is the perfect matching layer 5, which is the calculation boundary and auxiliary settings added when performing performance simulation by using the finite element method.

[0058] The base material 2 of the optical fiber is quartz; many air holes of different sizes are set in the quartz material, and the existence of air holes in the cladding reduces the effective refractive...

Embodiment 2

[0074] The structural parameters of the sensor in this embodiment are exactly the same as those in the first embodiment, and its characteristic description and performance characterization are also exactly the same as those in the first embodiment. This embodiment will specifically illustrate and further illustrate various usages of the invented sensor.

[0075] Figure 9 Shown is the schematic diagram of the specific operation and use instructions of the present invention. First, the two ends of the D-type photonic crystal fiber refractive index sensor described in the present invention are respectively fused with a single-mode fiber to form a sensor 102; then, one end of the sensor 102 is connected to a broadband light source 100 through a coupling device 101, and the other end of the sensor 102 is connected to the sensor 102. The inlet end of the beam splitter 103 is fused, and the two beams of light coming out of the beam splitter are respectively connected to a spectrome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com