Color wheel component, light source system and projection device

A component and color wheel technology, applied in the field of optics, can solve problems such as inconsistency, difficulty in synchronization, brightness attenuation of red phosphors, etc., to achieve the effects of avoiding attenuation, good system effect, and solving thermal quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

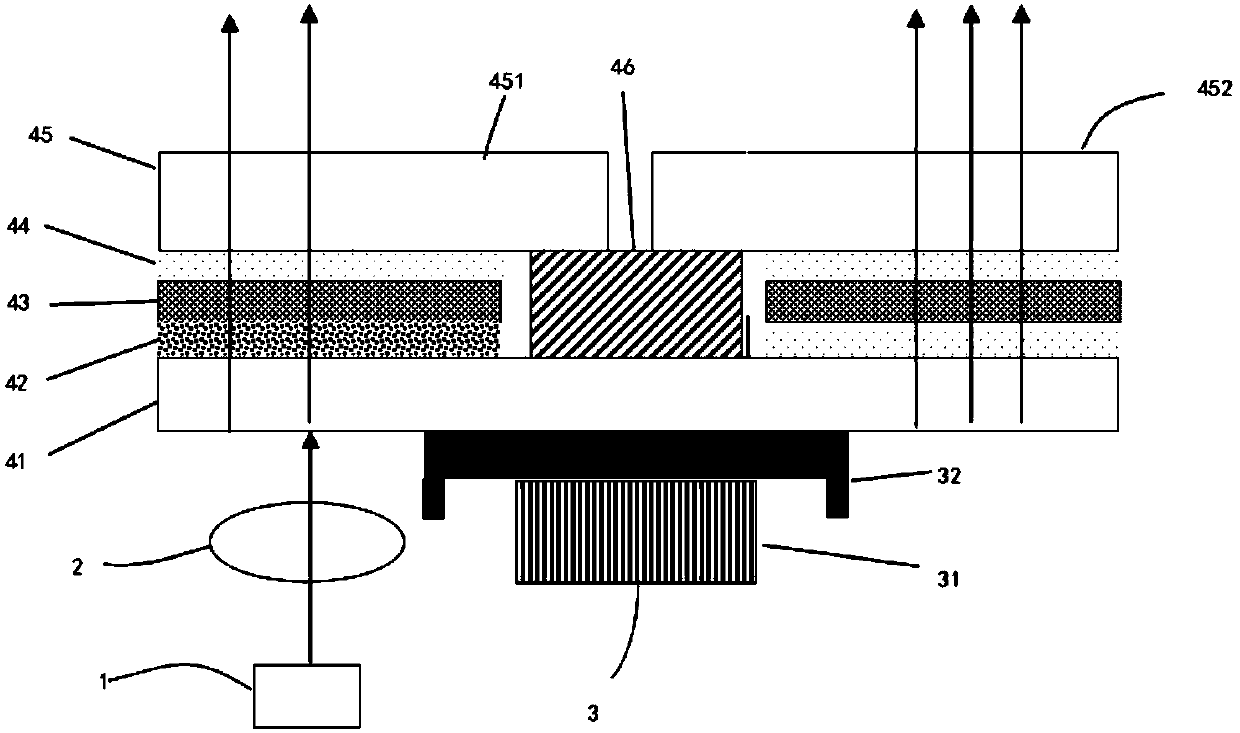

[0030] see figure 1 , The light source system of the present invention includes an excitation light source 1 , a relay lens 2 , a driving device 3 and a color wheel assembly 4 .

[0031] The excitation light source 1 is used to emit excitation light, and the excitation light is irradiated onto the color wheel assembly 4 through the adjustment of the relay lens 2 to realize wavelength conversion. The driving device 3 includes a driving motor 31 and a motor connection device 32 , and the color wheel assembly 4 rotates at a high speed driven by the driving device 3 .

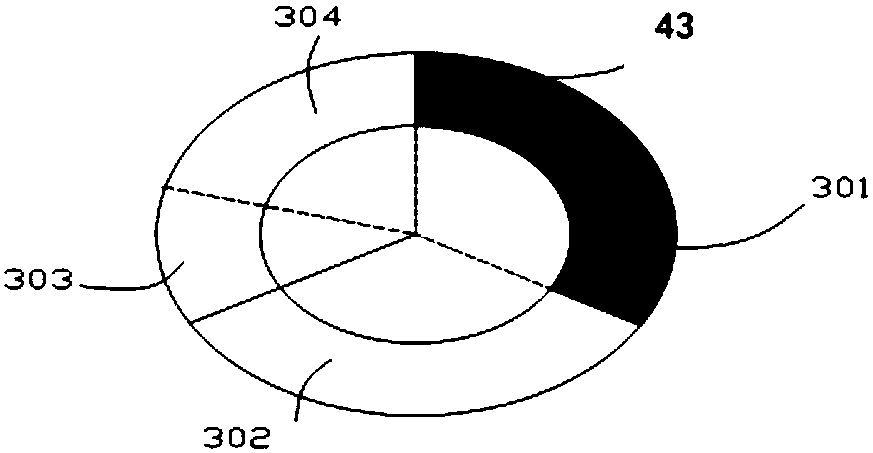

[0032] The color wheel assembly 3 includes a substrate layer 41 , a first gap layer 42 , a fluorescent layer 43 , a second gap layer 44 and a filter layer 45 arranged in sequence along the irradiation direction of the excitation light.

[0033] The substrate layer 41 is made of sapphire material, and has an anti-blue and transparent yellow layer that reflects blue light and transmits yellow light.

[0034] refer ...

Embodiment 2

[0045] This embodiment is substantially the same as the first embodiment, except that in this embodiment, the boron nitride and glass frit on the first void layer 42 are sprayed on the upper surface of the substrate layer 41, wherein the boron nitride The spraying thickness is 0.01-0.050um, and the spraying thickness of the glass powder is 0.01-0.050um.

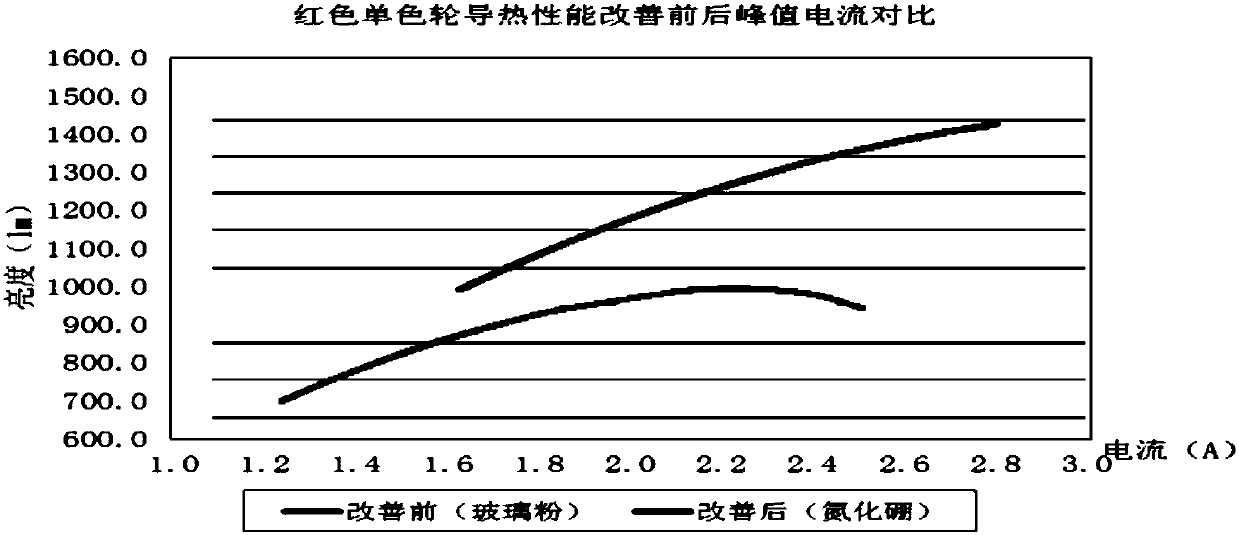

[0046] The beneficial effects of the present invention are: different from the situation of the prior art, one side of the light source system of the present invention corresponding to the red fluorescent area is provided with a boron nitride coating, the other side is provided with glass frit, and both sides of the non-red fluorescent area are uniform. Set with glass powder coating. By setting the boron nitride material at the corresponding position of the red fluorescent area, compared with the glass powder, the thermal conductivity of the boron nitride material is better, and the crystal structure of boron nitride is a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com