Capacitor for connecting IGBTs in parallel and manufacturing process and application method thereof

A capacitor and parallel technology, applied in the direction of multilayer capacitors, multiple fixed capacitors, fixed capacitor terminals, etc., can solve problems such as unreasonable design of drive and DC bus capacitors, single module current overload, and uneven module current. Eliminate the process of capacitor filling process, reduce volume and mass, and optimize the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

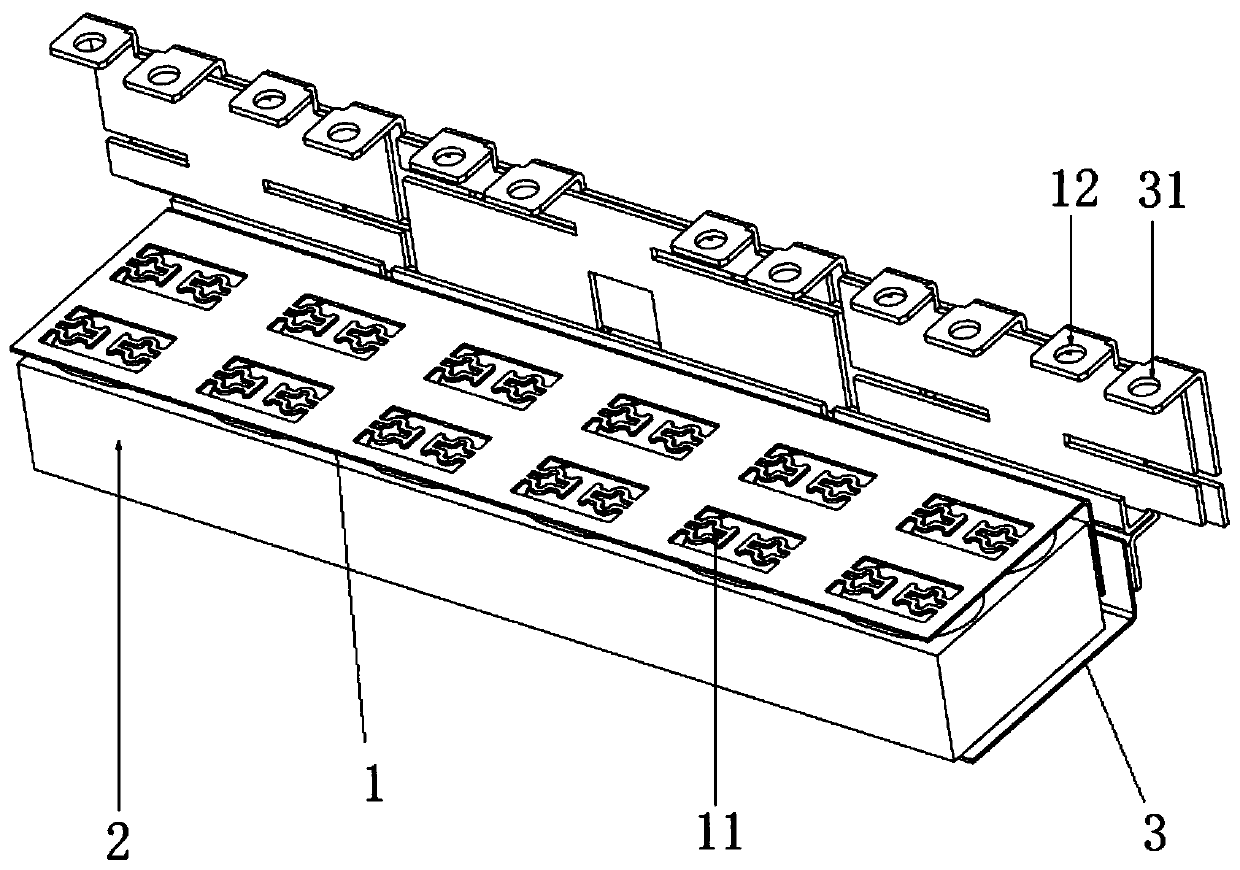

[0069] Embodiments of the present invention provide a capacitor for parallel IGBTs, including:

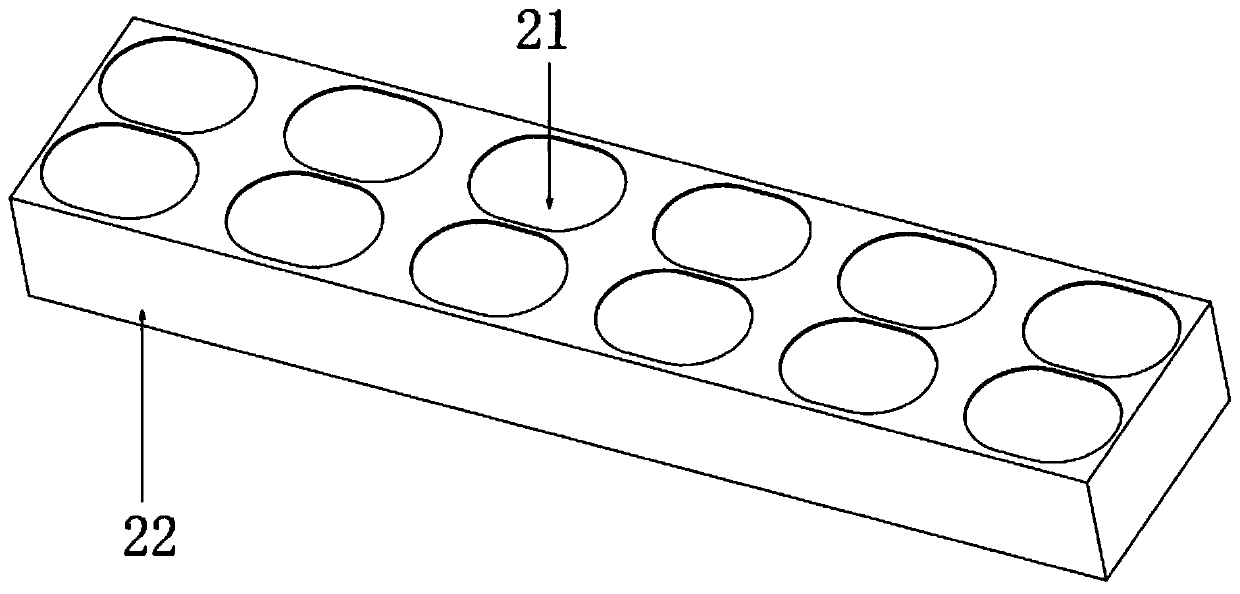

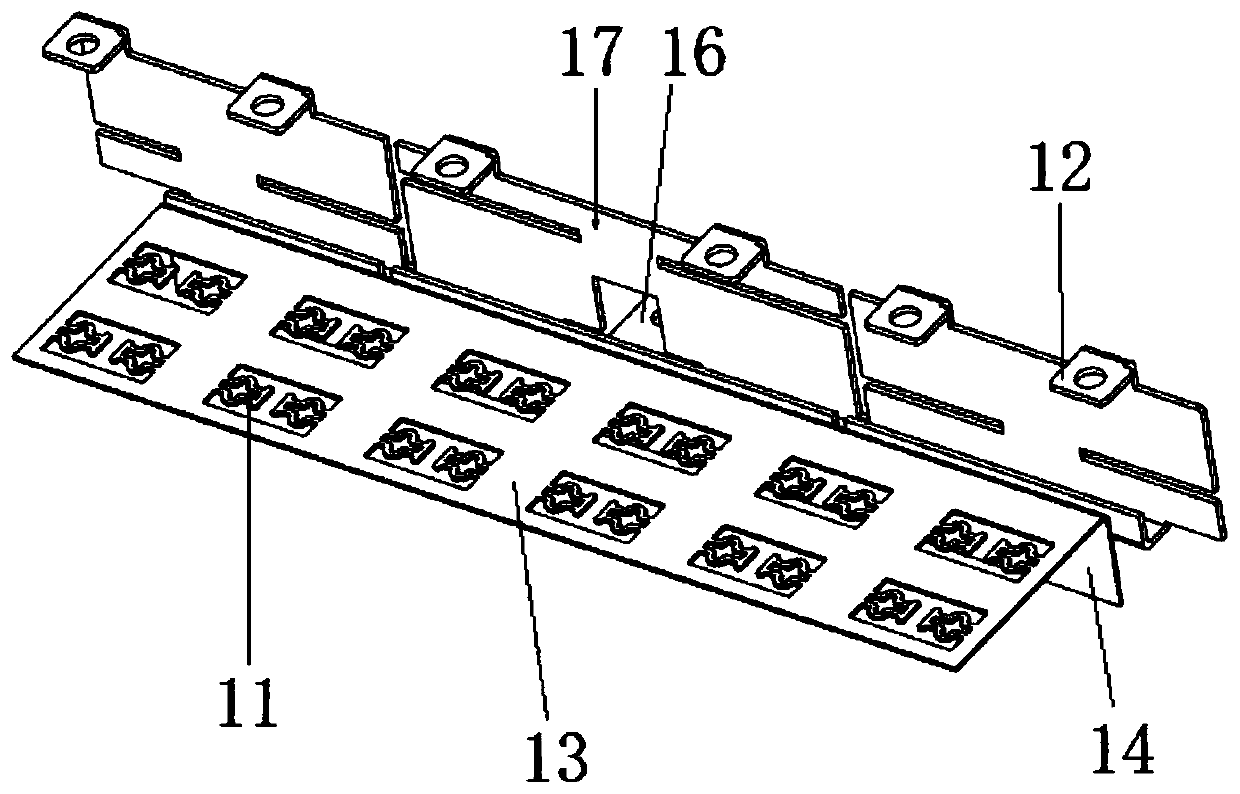

[0070] The core injection molding assembly 2, the core injection molding assembly 2 includes an injection molding body and a plurality of capacitive film cores arranged in an array and passing through the injection molding body;

[0071] The negative electrode copper bar 1 is connected to the upper surface of the core injection molding assembly 2, and the negative electrode copper bar 1 includes: a horizontally arranged negative electrode welding plate 13, a vertically arranged first connector 14, and a horizontally arranged second connection body 15, a vertically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com