Intelligent drying system for battery pole pieces and intelligent drying method for pole pieces

A battery pole piece and drying system technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of affecting the stability of the pole piece, unable to monitor the weight of the pole piece in real time, and unable to close the loop control pole Problems such as sheet drying, to achieve the effect of accurately controlling the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

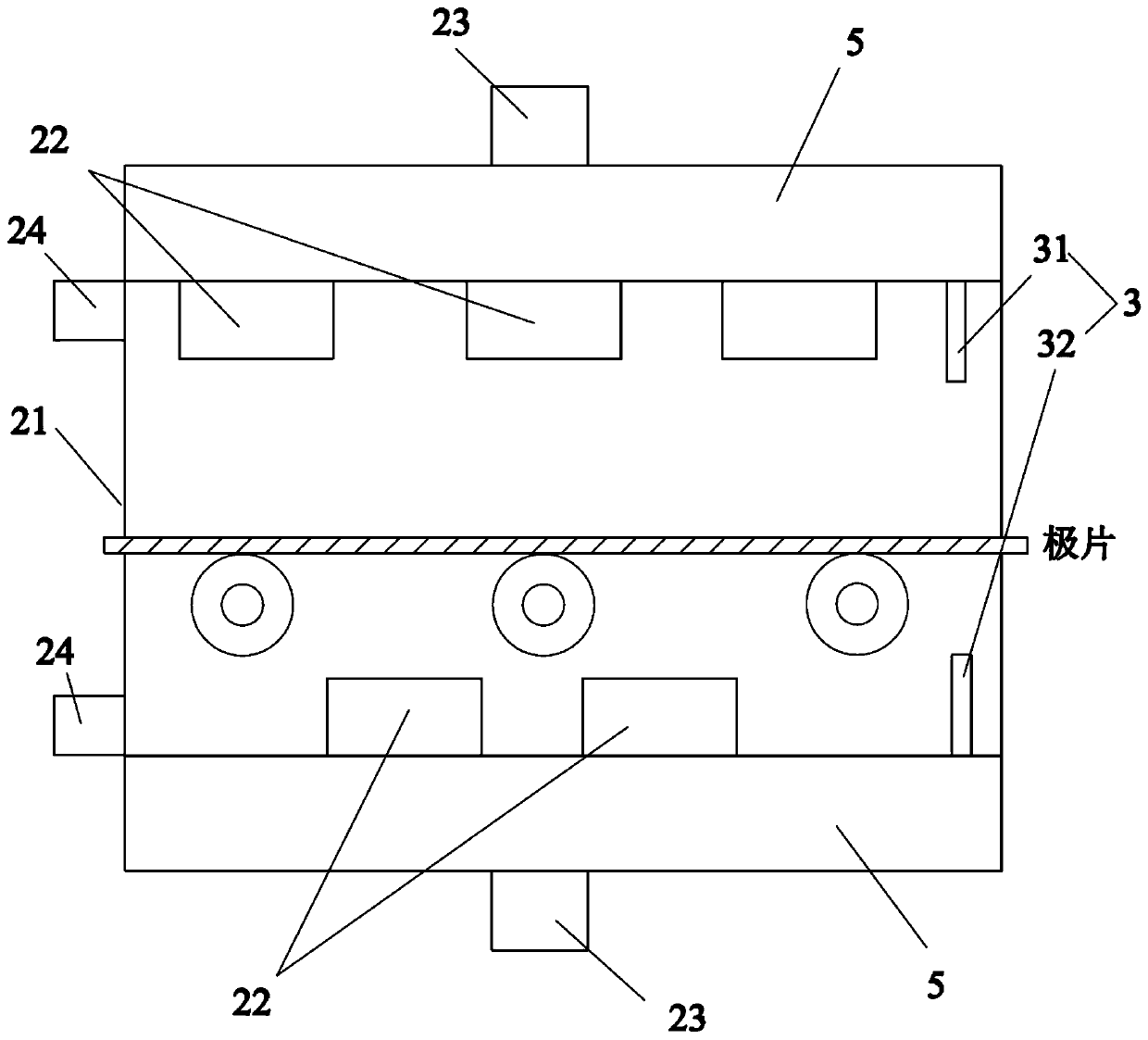

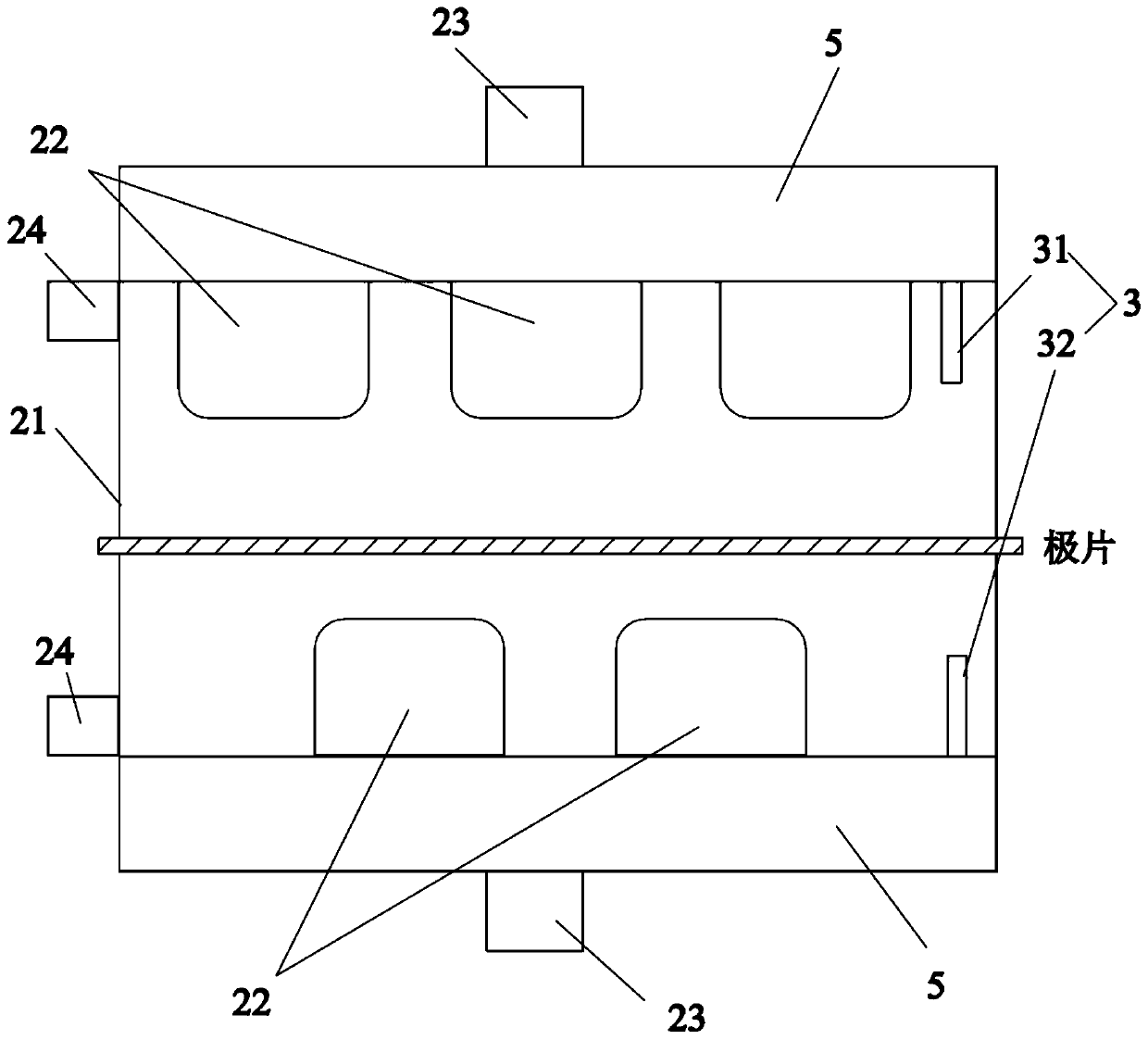

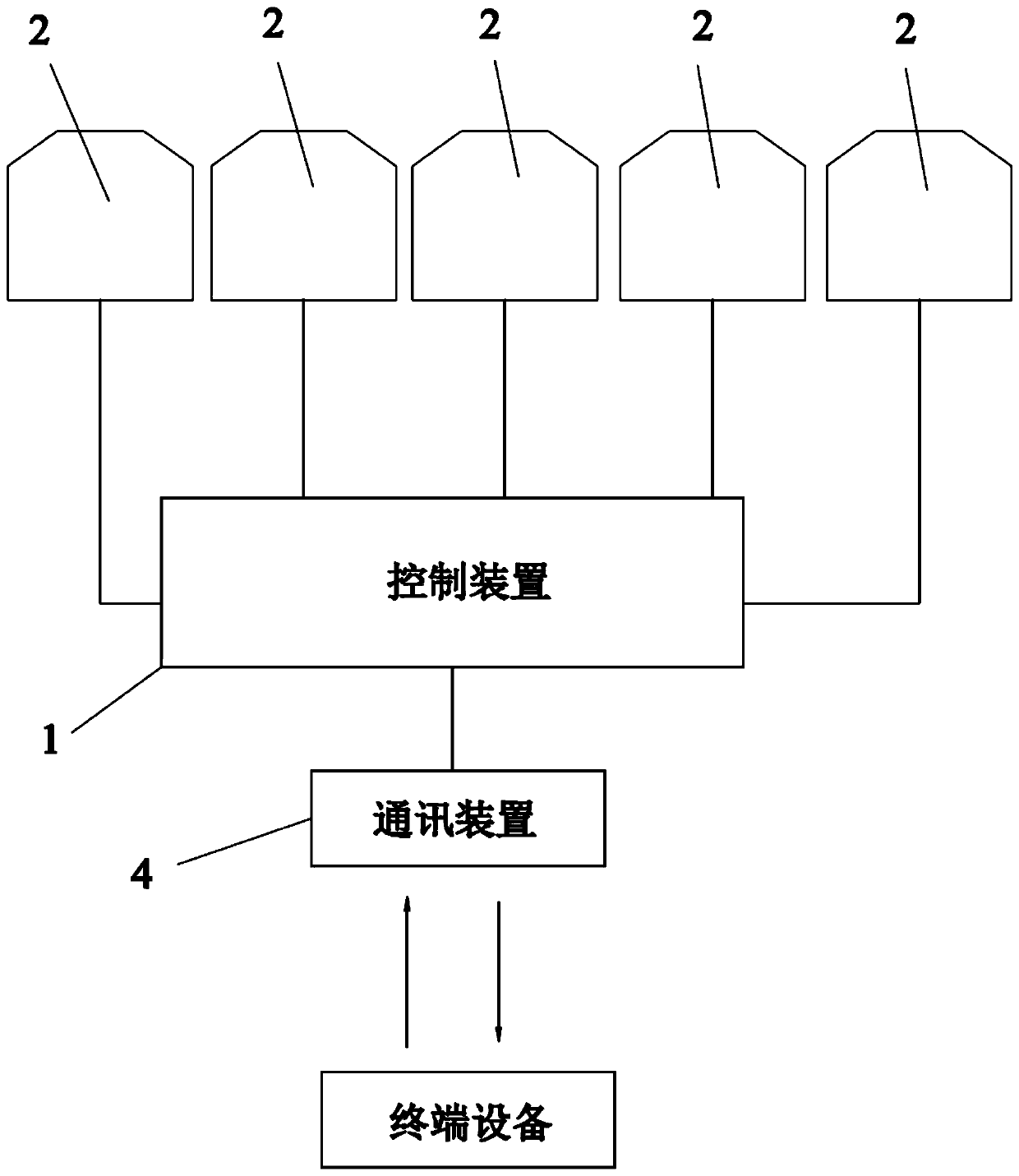

[0031]An intelligent drying system for battery pole pieces, comprising a control device 1 and several pole piece ovens 2, several pole piece ovens 2 are arranged along the pole piece moving direction, each pole piece oven 2 is equipped with a weight detection device 3, the pole piece Both the oven 2 and the weight detection device 3 are connected in communication with the control device 1; the weight detection device 3 is used to detect the weight of the pole piece, and feeds back to the control device 1; the control device 1 is used to receive the weight signal fed back by the weight detection device 3, and Control pole piece oven 2. In the existing battery pole piece coating process, the drying parameters of the oven are generally set directly, without monitoring the weight of the pole piece, the drying rate of the pole piece in the oven cannot be accurately controlled, and the adhesion of the pole piece fluctuates greatly , leading to unstable performance of the pole piece,...

Embodiment 2

[0041] The difference from Example 1 is that the pole piece oven 2 in this example is a suspension oven. In the suspension oven, the pole piece is transported by suspension, which helps to reduce the friction of the pole piece during transportation.

[0042] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0044] A method for intelligent drying of battery pole pieces, comprising the following steps:

[0045] Transfer the coated pole piece to the pole piece oven 2, and then detect the pole piece weight;

[0046] Analyze and judge whether the weight of the pole piece is within the preset range, if so, keep the drying parameters of the pole piece oven 2 unchanged; if not, adjust the drying parameters of the pole piece oven 2 until the weight of the pole piece is within the preset range. within the set range.

[0047] It should be noted that, in the drying method of the present invention, since the ratio of incident ray intensity attenuation and the weight per unit area penetrating the pole piece are in a negative exponential relationship, the ray intensity I when the incident ray is not blocked by the pole piece is collected. 0 , The ray intensity I after the incident ray penetrates the pole piece, combined with the absorption coefficient λ per unit area of the pole piece, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com