Efficient compatilizer for polyolefin-based wood-plastic composite

A wood-plastic composite material and polyolefin-based technology, which is applied in the field of high-efficiency compatibilizers for polyolefin-based wood-plastic composite materials, can solve problems such as increased costs, uneven melting, and insufficient heating, so as to prolong service life and improve compatibility. Capacitive, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

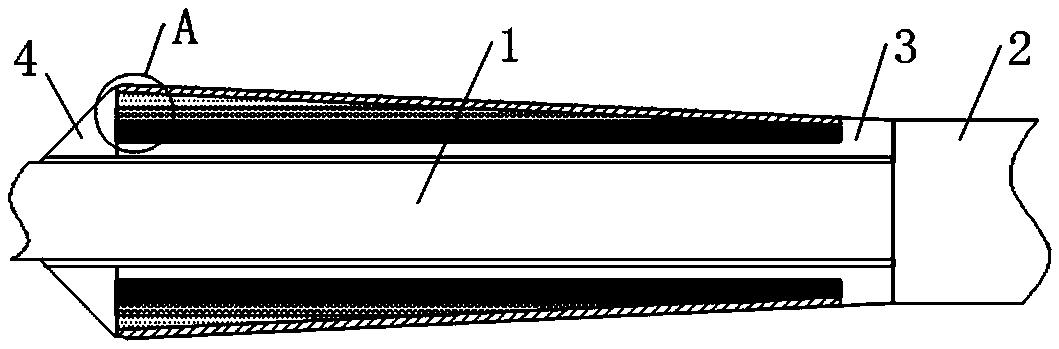

[0041] see Figure 1-2 , a high-efficiency compatibilizer for polyolefin-based wood-plastic composites, including the following components in parts by mass: 100 parts of EAA, 5 parts of 2-acrylic acid-2-hydroxyl-3-phenoxy Propyl ester, 3 parts of cetyl methacrylate, 0.5 part of DCP, 0.6 part of tetraisopropyl titanate.

Embodiment 2

[0043] see Figure 1-2 , a high-efficiency compatibilizer for polyolefin-based wood-plastic composites, including the following components in parts by mass: 100 parts of EAA, 6 parts of 2-acrylic acid-2-hydroxyl-3-phenoxy Propyl ester, 4 parts of cetyl methacrylate, 0.3 part of DCP, 0.5 part of tetraisopropyl titanate.

Embodiment 3

[0045] see Figure 1-2 , a high-efficiency compatibilizer for polyolefin-based wood-plastic composites, including the following components in parts by mass: 100 parts of EAA, 5 parts of 2-acrylic acid-2-hydroxyl-3-phenoxy Propyl ester, 5 parts of cetyl methacrylate, 0.4 parts of DCP, 0.7 parts of tetraisopropyl titanate.

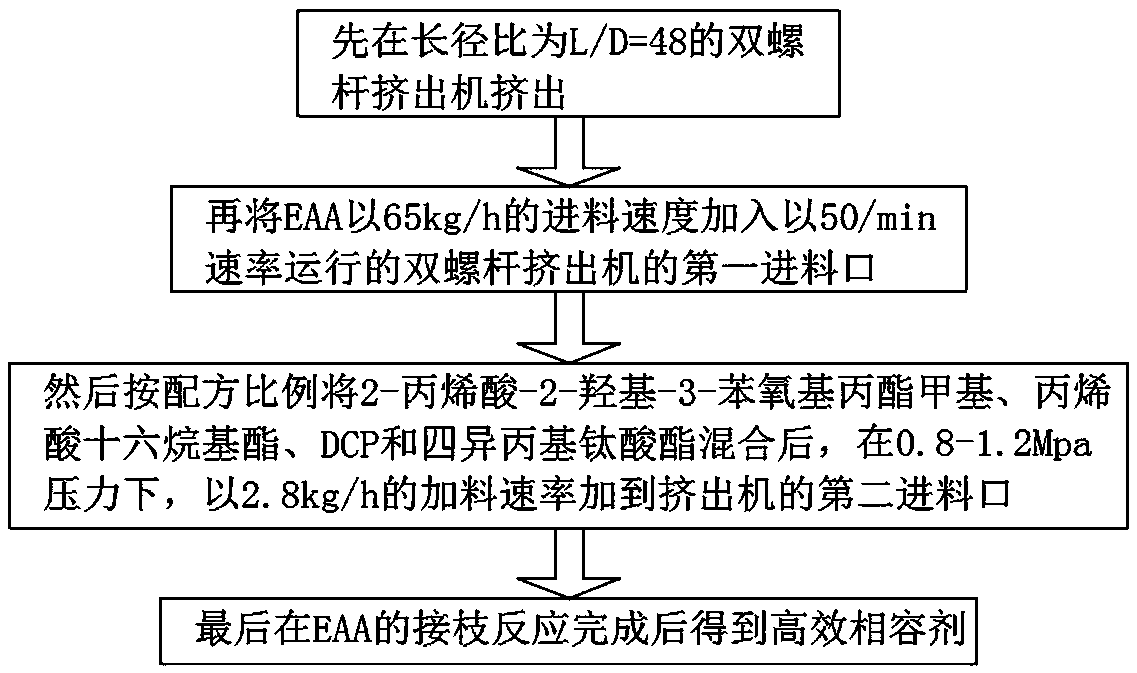

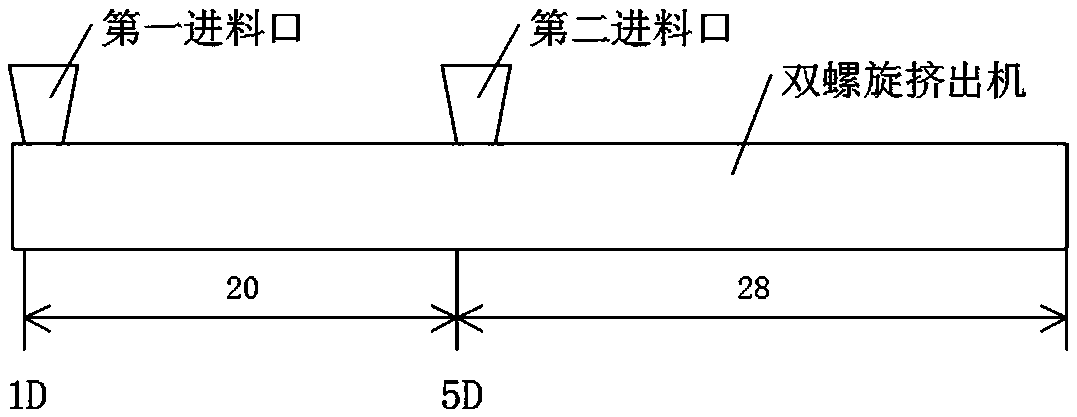

[0046] The preparation method of the high-efficiency compatibilizer is to first extrude the extruder with a twin-screw with a length-to-diameter ratio of L / D=48, the extruder includes a first feed port and a second feed port, and then EAA Add the first feeding port of the twin-screw extruder that moves with 50 / min speed with the feeding speed of 65kg / h, then by formula ratio, 2-acrylic acid-2-hydroxyl-3-phenoxypropyl ester methyl , hexadecyl acrylate, DCP and tetraisopropyl titanate are mixed, under the pressure of 0.8-1.2Mpa, add to the second feeding port of the extruder at a feeding rate of 2.8kg / h, and finally After the grafting reaction of EAA is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com