Electron beam curing compound adhesive, flexible package compound film and preparation method thereof

An electron beam curing, flexible packaging film technology, applied in the field of curing glue, can solve the problems of low efficiency, limited use time of mixed glue, etc., and achieve the effect of strong penetration, excellent coating performance and wetting performance, and high energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

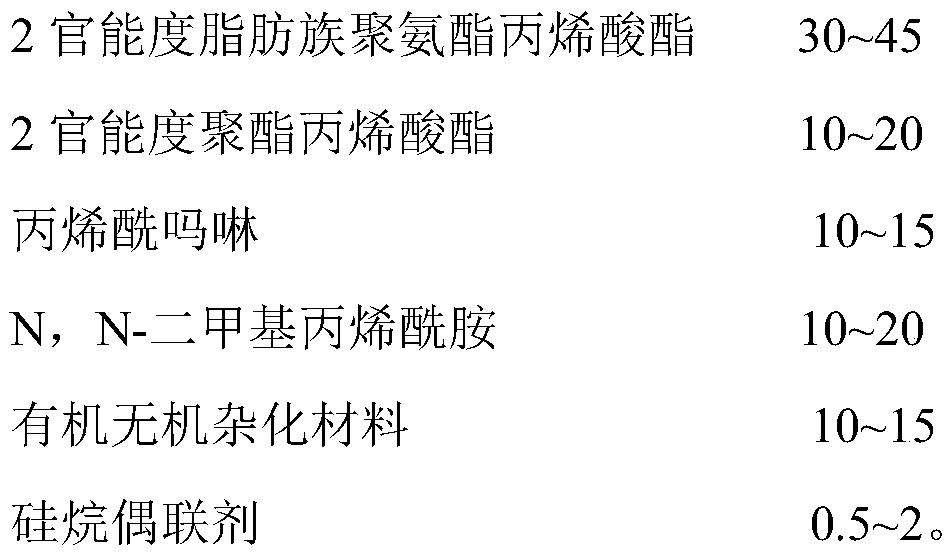

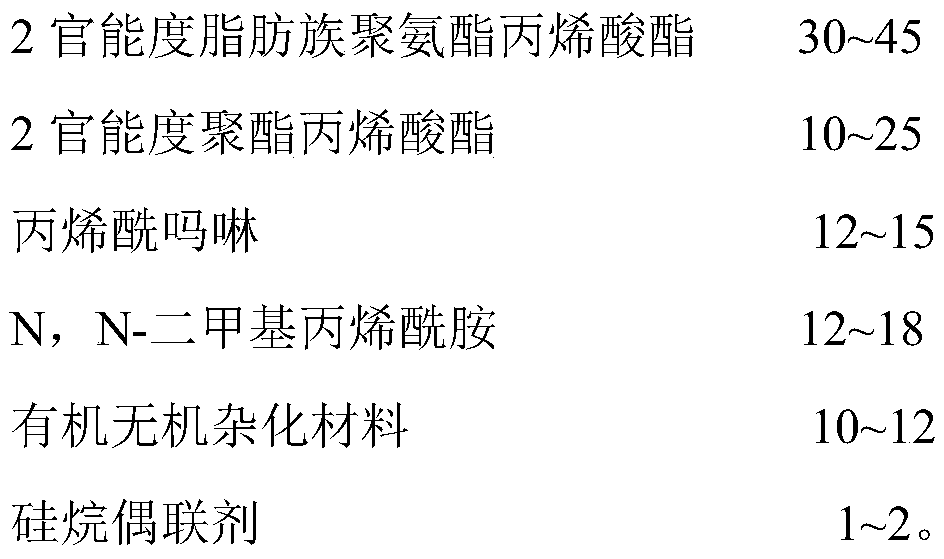

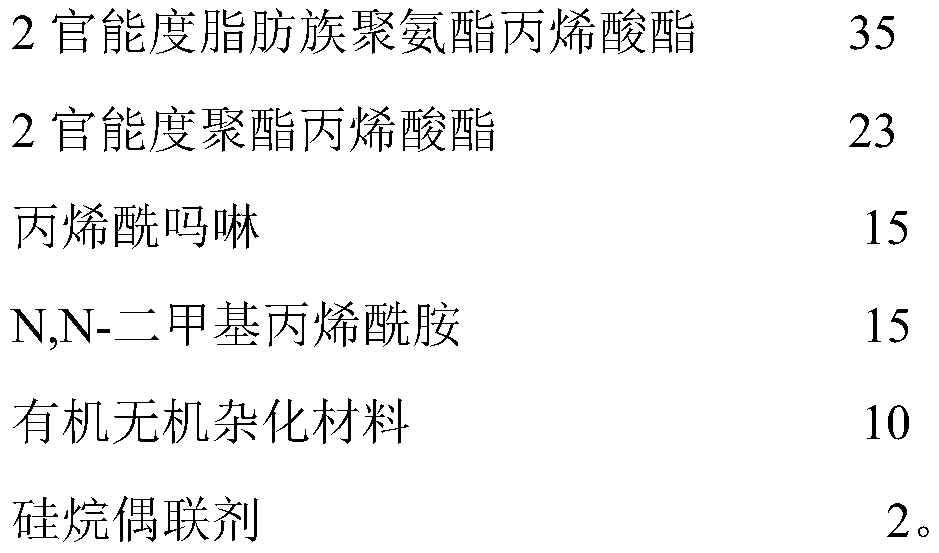

[0057] The electron beam curing composite glue provided in this embodiment is made of the following raw materials with the following mass ratios:

[0058]

[0059] in:

[0060] The bifunctional aliphatic urethane acrylate is purchased from Taiwan Changxing Chemical Eternal, the model is DR-U301, and the weight average molecular weight is 15,000-20,000.

[0061] The 2-functionality polyester acrylate is a modified 2-functionality polyester acrylate resin, which is purchased from Foshan Dechuang United Polymer Material Co., Ltd., and the model is UV938A.

[0062] The organic-inorganic hybrid material 604X35 was purchased from Taiwan Changxing Chemical.

[0063] Silane coupling agent SN-7535 was purchased from Shanghai Shenzhu Chemical Industry.

[0064] The flexible packaging composite film prepared by the above-mentioned electron beam curing composite glue can be used.

[0065] The preparation method of the flexible packaging composite film comprises the following steps: ...

Embodiment 2

[0073] Different from Example 1, the first flexible packaging film is polyethylene terephthalate film (PET) in the step (2), and the second flexible packaging film is polyethylene film (PE), and what makes is PET / PE.

Embodiment 3

[0075] The difference from Example 1 is that in step (2), the first flexible packaging film is a biaxially oriented polyamide film (NY), and the second flexible packaging film is a polyethylene film (PE), which is NY / PE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com