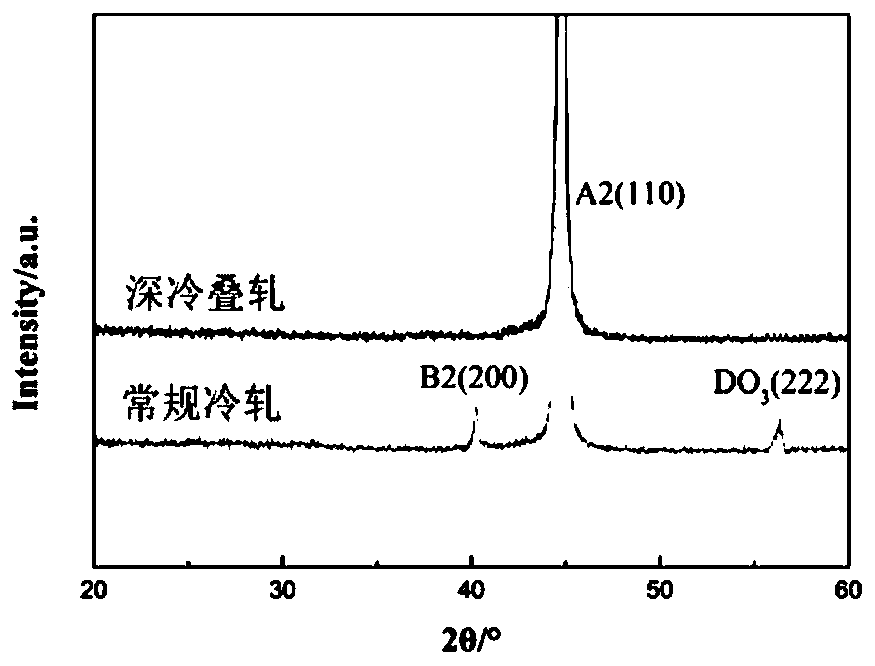

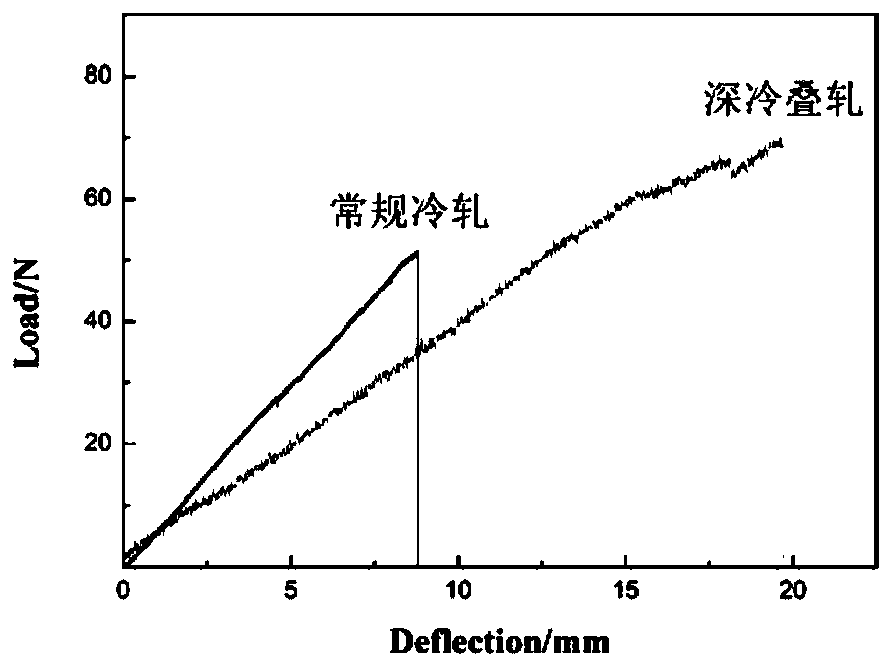

High-silicon steel sheet and cryogenic pack rolling technology for preparing same

A high-silicon steel and sheet technology, applied in the field of steel rolling, can solve the problems of difficult cold rolling deformation, large deformation resistance, coarse grain size, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 6.91%, Al 0.4%, Y 0.008%, Zr 0.05%, C 0.007%, Mn 0.008%, P 0.005%, S 0.004% , N0.002%, O 0.002%, the balance Fe.

[0030] At a temperature of 1200°C, after holding for 140 minutes, the billet is free forged into a 40mm thick billet by air. The heating temperature of the slab hot rolling is 1150°C, and the heat preservation is 100min. After the heat preservation, the non-lubricated hot rolling is carried out on the two-roller reversible experimental hot rolling mill and hot rolled to 3.5mm by 12 passes. The starting rolling temperature is 1150°C, and the final rolling is The temperature was 900°C, and then cooled to room temperature in air. The hot-rolled plate was pickled with 5% hydrochloric acid solution, the pickling temperature was 50°C, and the pickling time was 10 min to remove the surface oxide scale.

[0031] The pickled plate is heated t...

Embodiment 2

[0035] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 6.95%, Al 0.55%, Y 0.015%, Zr 0.065%, C 0.007%, Mn 0.008%, P 0.005%, S 0.004% , N0.002%, O 0.002%, the balance Fe. At a temperature of 1230°C, after 90 minutes of heat preservation, air free forging was used to form a 35mm thick billet. The heating temperature of the slab hot rolling is 1180°C, and it is kept for 90 minutes. Then, it is hot-rolled without lubrication on a two-roll reversible experimental hot rolling mill and hot-rolled to 3.0mm after 11 passes. The starting rolling temperature is 1130°C, and the final rolling temperature is to 880°C, then air-cooled to room temperature. Use 6% concentration of hydrochloric acid solution to pickle the hot-rolled plate, the pickling temperature is 60°C, and the pickling time is 15min to remove the surface oxide scale.

[0036] Put the pickled plate in a heating furnace and heat it to 580°C. After ...

Embodiment 3

[0040] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 6.98%, Al 0.7%, Y 0.02%, Zr 0.08%, C 0.008%, Mn 0.007%, P 0.005%, S 0.004% , N0.002%, O 0.002%, the balance Fe. At a temperature of 1250°C, after holding for 80 minutes, the billet was free-forged into a 30mm-thick billet by air. The heating temperature of the slab hot rolling is 1200°C, and it is kept for 80 minutes. Then it is hot-rolled without lubrication on a two-roll reversible experimental hot rolling mill and hot-rolled to 2.5mm after 12 passes. The starting rolling temperature is 1100°C, and the final rolling temperature is to 870°C, then air-cooled to room temperature. Use 8% hydrochloric acid solution to pickle the hot-rolled plate, the pickling temperature is 70°C, and the pickling time is 20min to remove the surface oxide scale.

[0041] Put the pickled plate in a heating furnace and heat it to 620°C. After holding for 5 minutes, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com