Transformer oil heating device and method for large fire test

A transformer oil and heating device technology, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of slow heating rate, high oil temperature, easy accidental ignition of transformer oil, etc., and achieve fast speed and heating The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

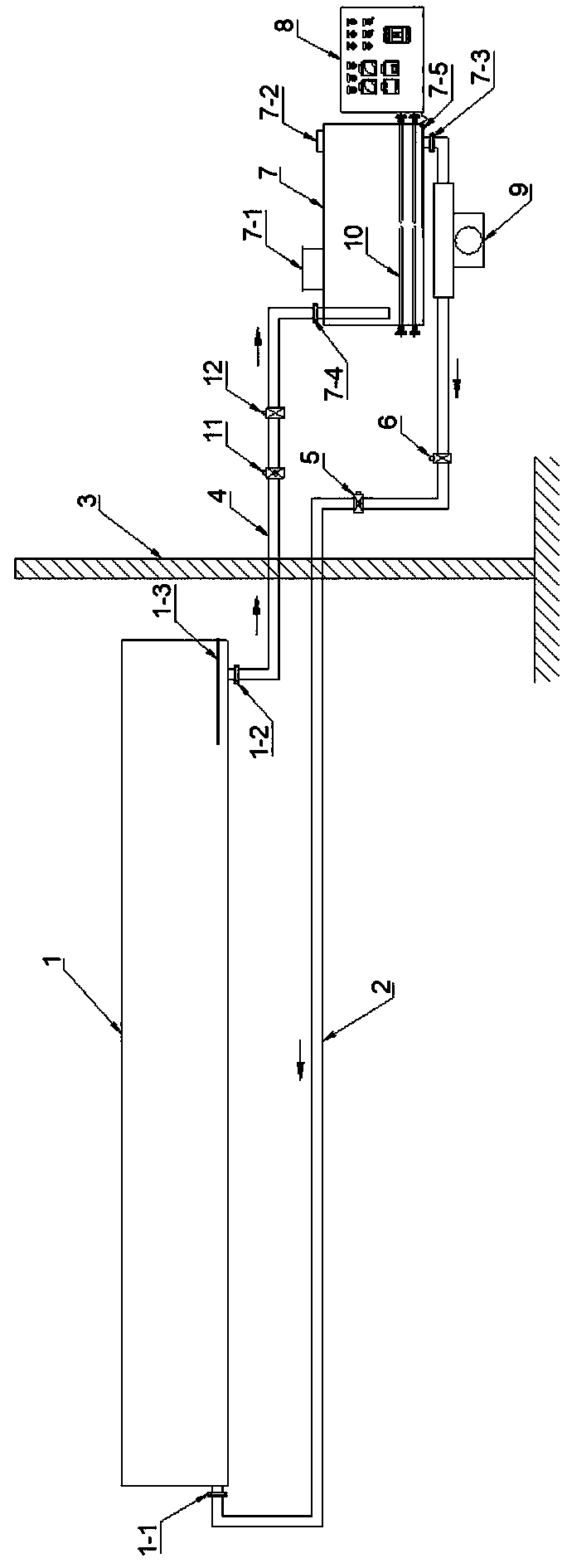

Method used

Image

Examples

Embodiment 1

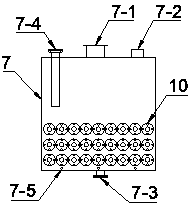

[0017] The hot oil pump adopts LQRY100 single-stage high-temperature heat-conducting oil pump.

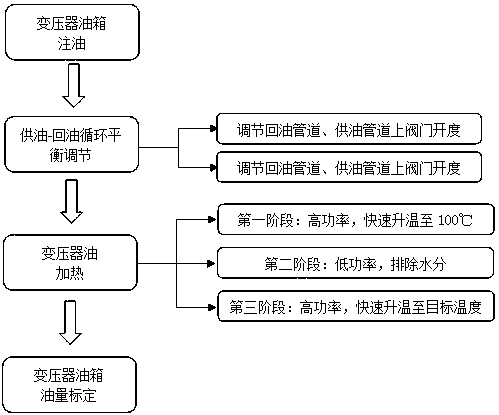

[0018] The lower part of the heating tank is evenly equipped with three sets of electric heating tubes. Each set of electric heating tubes contains twelve electric heating tubes. The electric heating tubes use EH-15 type heating rods. , the heating tank control cabinet contains three on-off switches, which are heated by the two-stage three-stage heating method as shown in Table 1. Each on-off switch controls a group of electric heating tubes, and by turning on 1 group, 2 groups or 3 groups of electric heating Tubes, so as to achieve three different heating powers, and can also use a single electric heating tube with different powers to achieve more different heating powers.

[0019] Table 1 Two-stage three-stage heating method

[0020] stage Heating power / kW Target temperature / ℃ Remark The first stage 540 100 High power heating, rapid heating second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com