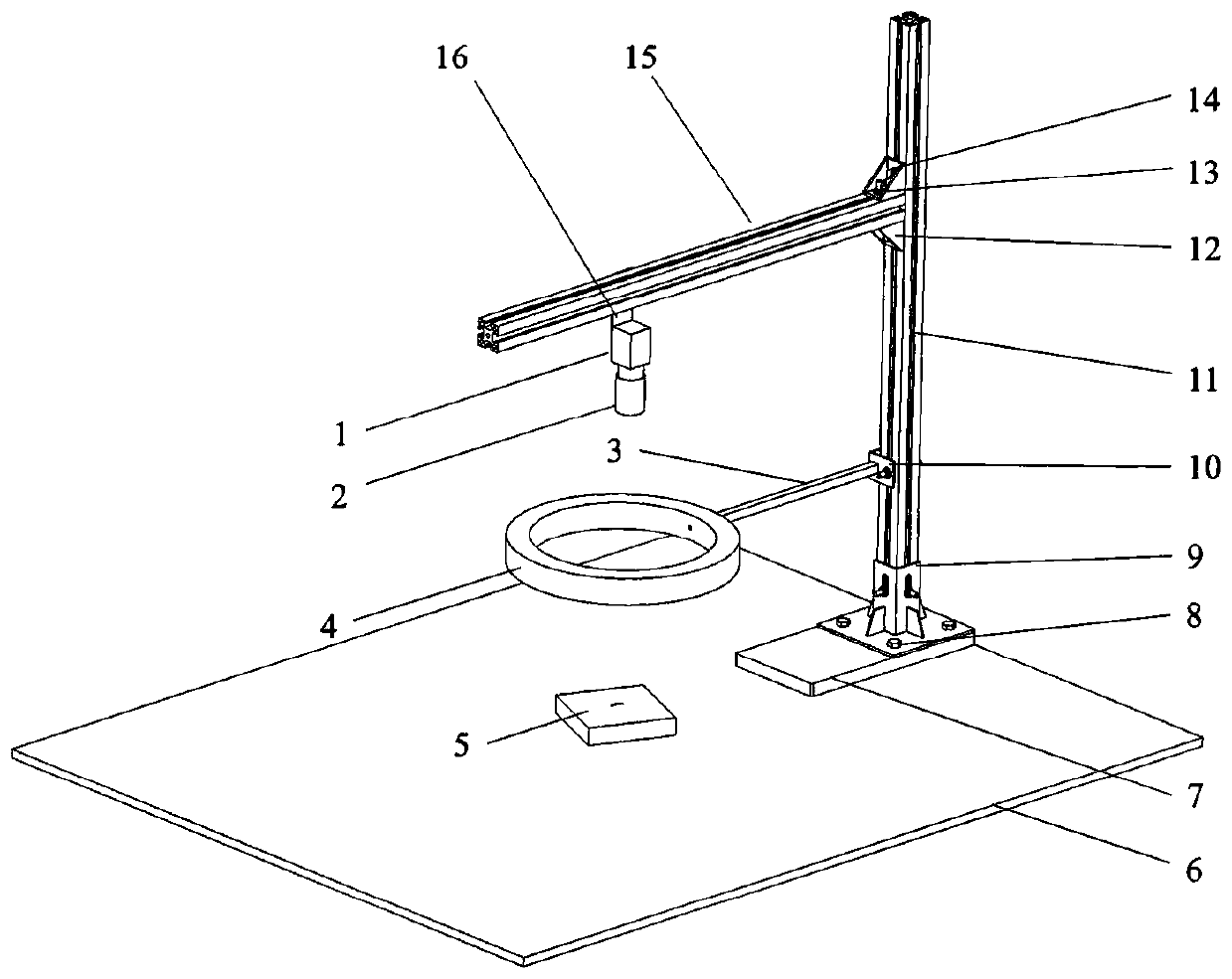

Metal ceramic part identification and surface defect detection system and method

A defect detection and cermet technology, which is applied in the direction of optical defect/defect test, measuring device, image data processing, etc., can solve the problems of inability to realize part recognition, low sensitivity, instability, etc., and achieve the effect of high-efficiency automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

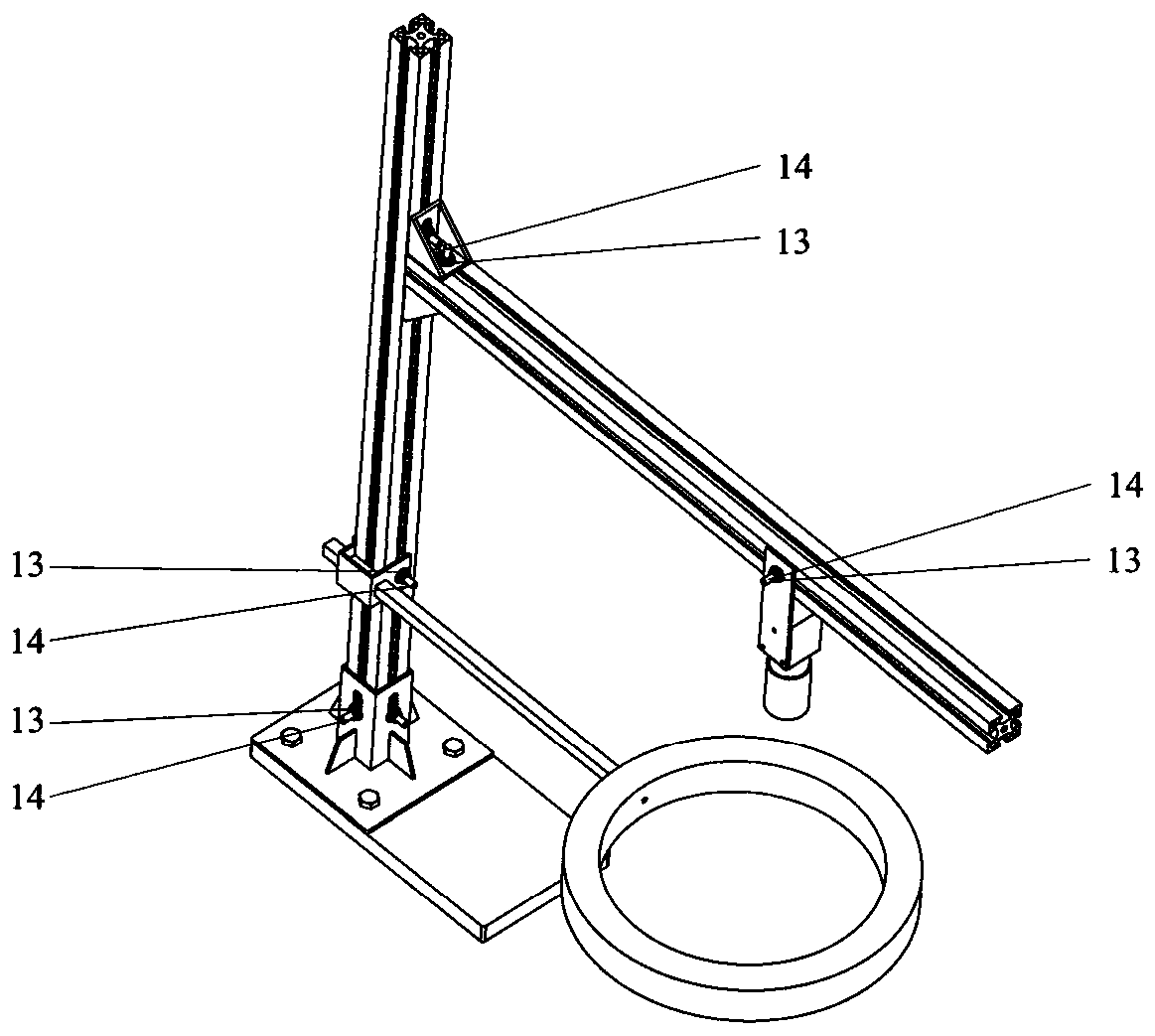

Method used

Image

Examples

specific Embodiment

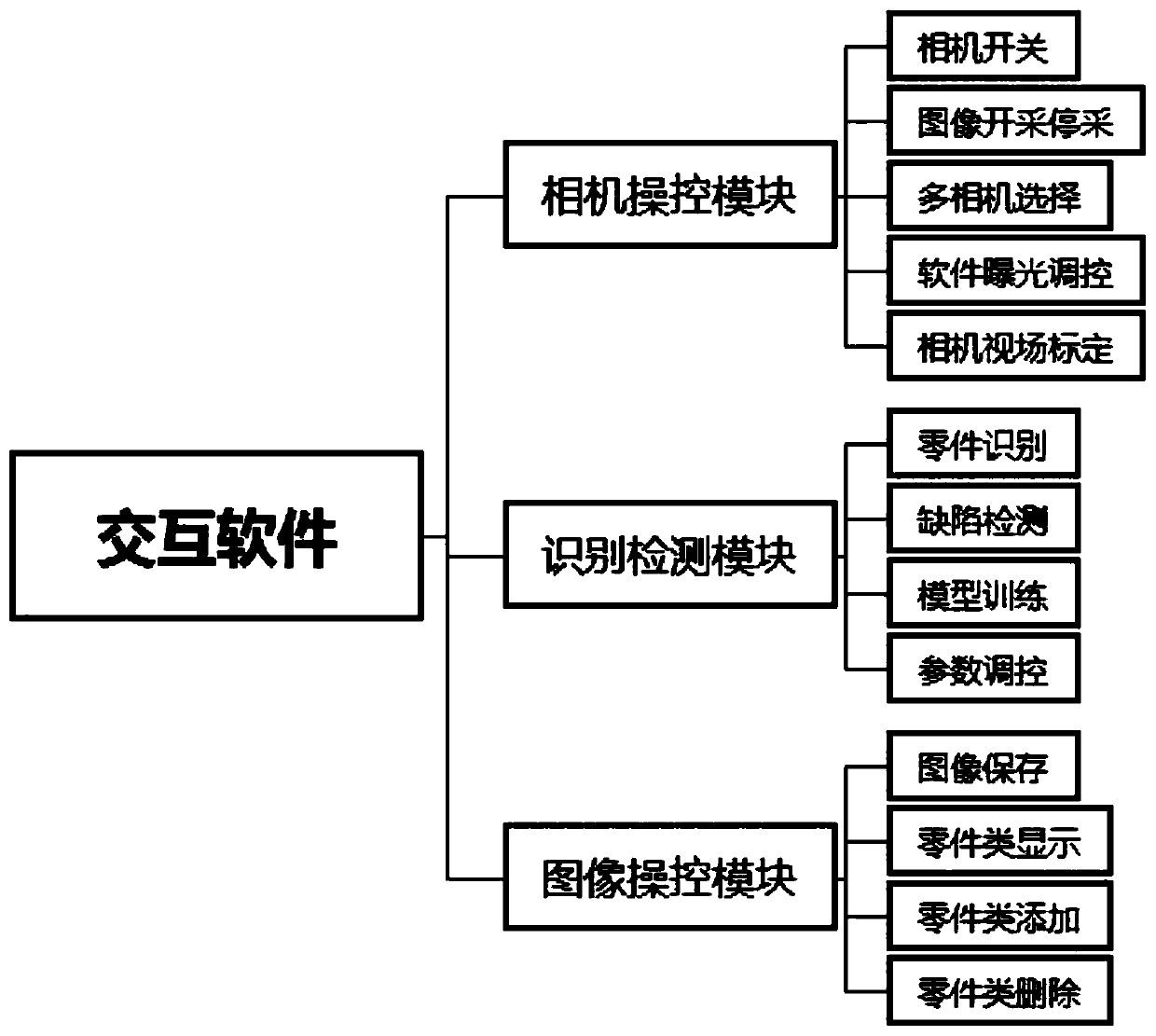

[0061] Step 1: Collect the original RGB color image through the camera control module

[0062] Click the Open Camera and Start Acquisition buttons successively in the camera control module, and select the camera number to be used from the multi-camera selection drop-down list, and the original image returned by the camera can be received and displayed in real time. Adjust the lens aperture or use the software exposure control function to process the original image brightness to ensure that the obtained original image will not be overexposed or too dark. If the field of view of the camera has changed a lot after the last system use, you can use the camera calibration function to realize automatic calibration of the field of view by using the double circle diagram and Hough circle detection and distance mapping method, and write the calibration coefficient to Enter the local configuration file for easy calling. After the above operations are completed, high-quality original RGB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com