A solid material permittivity sensor based on siw-csrr structure

A solid material, dielectric constant technology, applied in the direction of dielectric property measurement, instrument, measurement of electrical variables, etc., can solve the problem of low test accuracy, and achieve the effect of low sample preparation requirements, simple experimental process, and simple test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

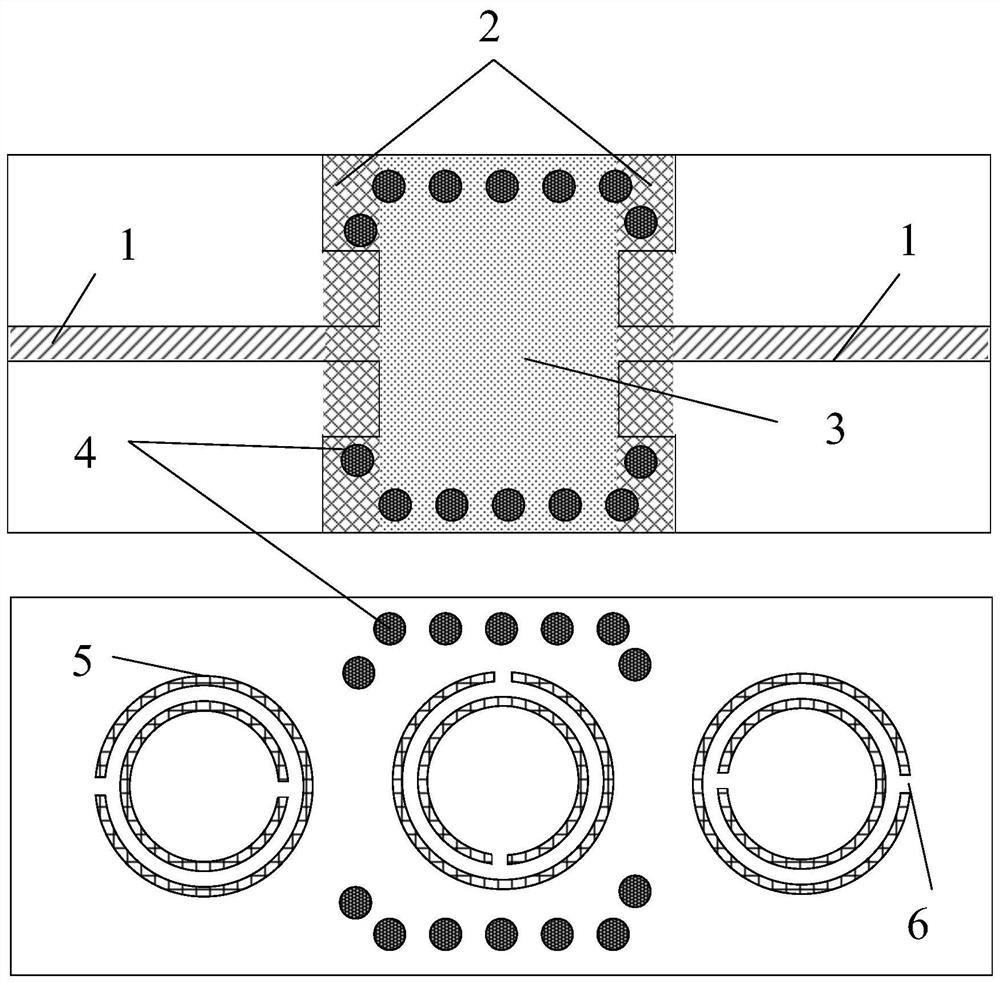

[0026] figure 1 The schematic diagram of the solid material dielectric constant sensor structure based on the SIW-CSRR structure provided by the present invention, as shown in the figure, the sensor includes a front microstrip line structure, a dielectric substrate in the middle and a back ground metal plate; the front microstrip structure is up and down Symmetrical structure, including input microstrip line as 50 ohm microstrip line and 50 ohm output microstrip line, line width 1.1mm, length 10mm, followed by coplanar waveguide structure, coplanar waveguide central conduction bandwidth 1.1mm, length 1.8 mm, the width of the transverse slit in the middle is 2.4mm; both sides of the dielectric substrate in the middle are metallized via holes, the diameter of the via hole is 1mm, the distance between adjacent via holes is 1.8mm, and the inner wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com