A COP/CO with high HER and OER catalytic activity 2 The preparation method of p composite catalyst

A composite catalyst and a technology of catalytic activity, applied in the field of electrocatalysis, can solve the problems of unsatisfactory catalytic activity of transition metal phosphide electrocatalysts, etc., and achieve the effects of high electrochemical stability and ignition point, low cost, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

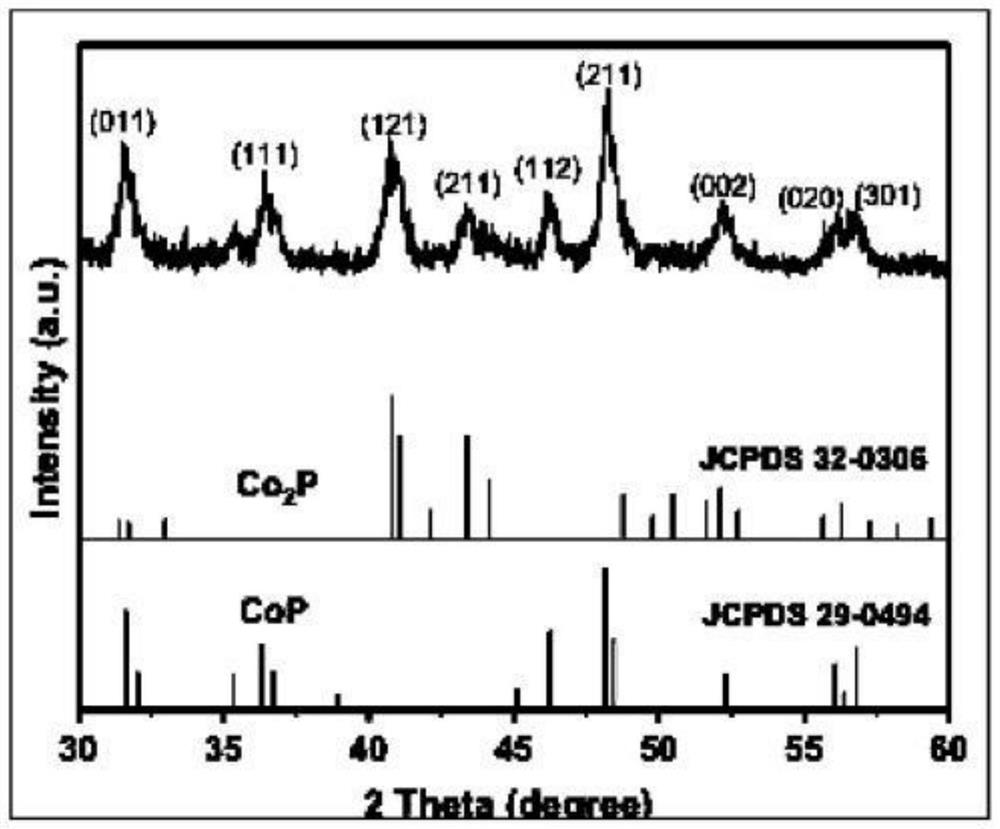

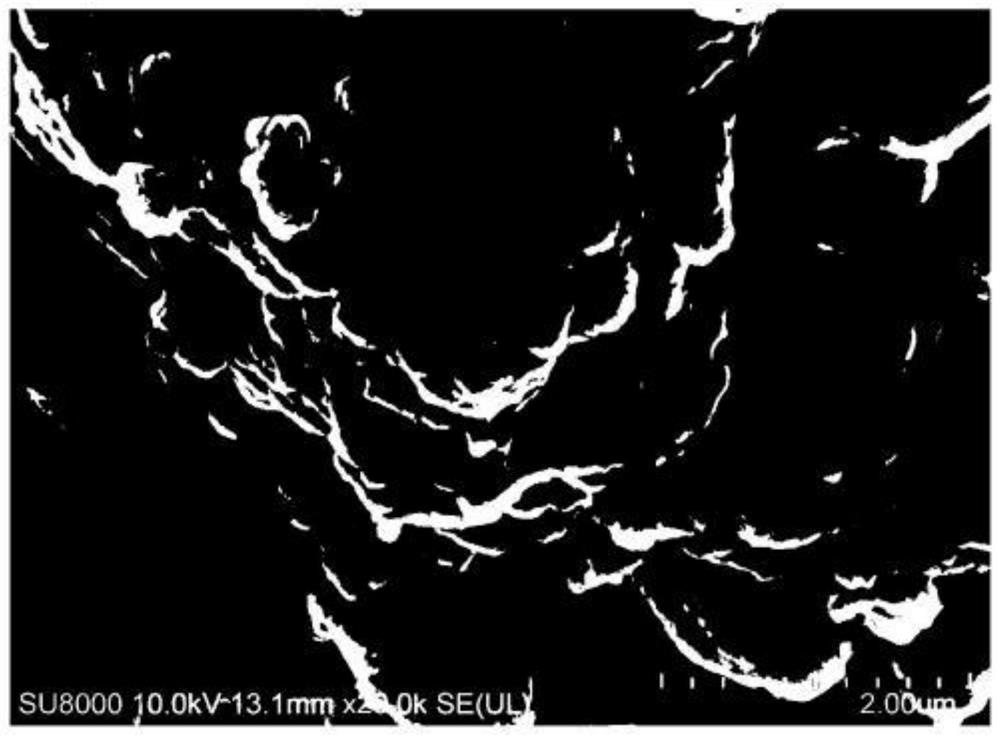

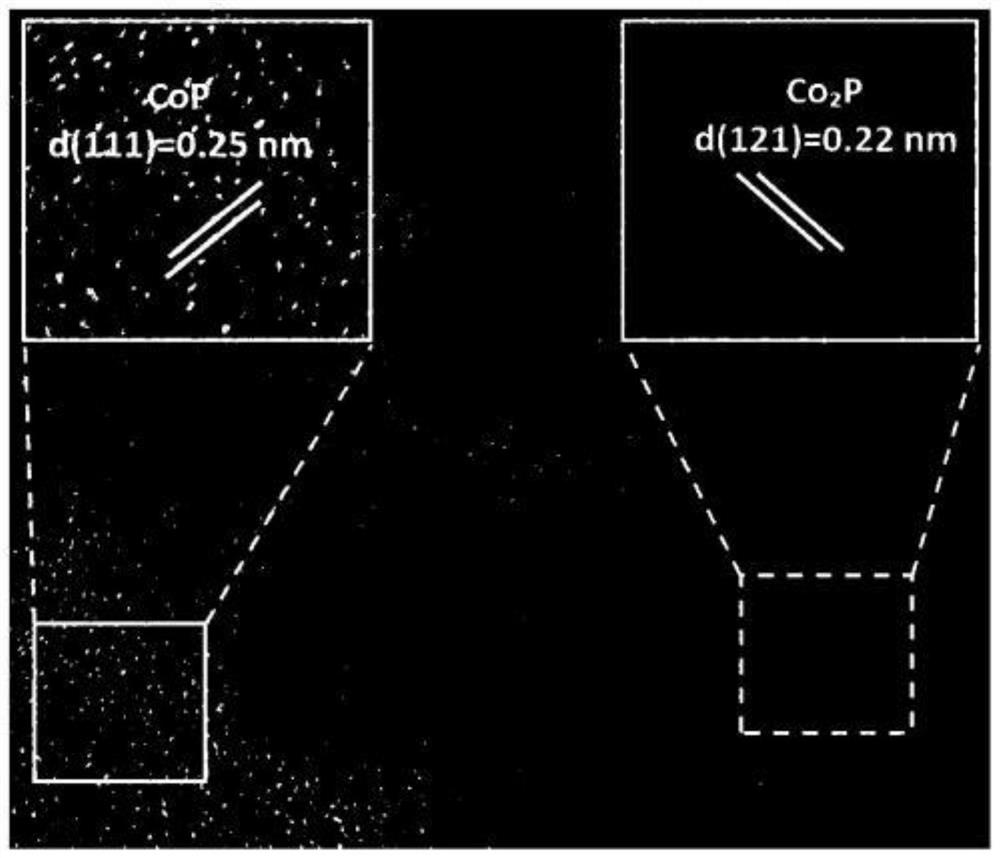

[0023] Weigh 2.5g of cobalt trioxide powder and 1.0g of self-made black phosphorus into a high-energy ball mill jar, add 72g of stainless steel balls, and seal. Set the low temperature to 25°C, the high temperature to 45°C, the rotation speed to 1200r / min, and ball mill for 2 hours to obtain 3.23g CoP / Co 2 P composite electrocatalyst.

[0024] Take 10mg of the resulting CoP / Co 2 The P composite electrocatalyst was placed in the sample tube, followed by adding 450 μL of isopropanol and 50 μL of naphthol solution, and ultrasonicated for 1 h to prepare a suspension. The suspension was drop-coated on a rotating disk electrode (platinum carbon), with Ag / AgCl as the reference electrode and platinum wire as the counter electrode, and its electrocatalytic HER was measured. The suspension was drop-coated on graphite sheets, one as the cathode and the other as the anode, and its catalytic performance for total water splitting was measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com