A Modification Technology of Small Pressure Mold

A pressure mold and process technology, applied in the field of small pressure mold transformation technology, can solve the problems of reduced mold service life, many pressing variables, blurred handwriting, etc., and achieve the effect of improving service life, ensuring safe production, and reducing the number of pressing times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

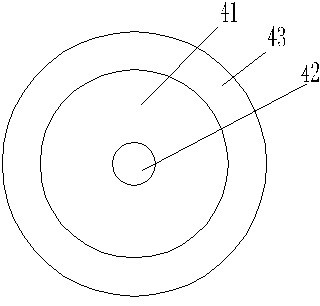

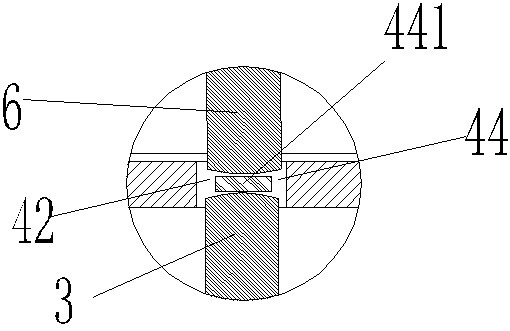

[0023] like Figure 1-4 A small pressure mold modification process shown includes the following steps:

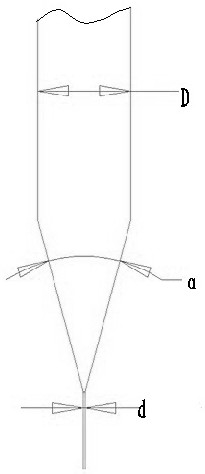

[0024] 1) Tool processing: Use a 1200-mesh oilstone to manually form a micro-arc knife tip with an end diameter of 0.04mm under a microscope. The diameter D of the tapered flat-bottomed knife is 3mm, the taper α is 30 degrees, and the bottom diameter d is 0.04mm;

[0025] 2) Processing of the lower spherical surface: The lower spherical surface is processed with a tapered flat-bottomed knife. In the processing of the lower spherical surface, the arc surface model is first established, and the text or relief pattern is projected onto the arc surface design path, and the path distance is 0.01mm. The dense path distribution is conducive to the smoothness of the engraving plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com