Recycled concrete from construction waste

A technology for recycled concrete and construction waste, applied in the field of concrete, can solve the problems of low bulk density of recycled fine aggregate, affect the impermeability of recycled concrete, rough surface of recycled coarse aggregate, etc., so as to accelerate the hydration speed and prolong the hydration time, the effect of improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

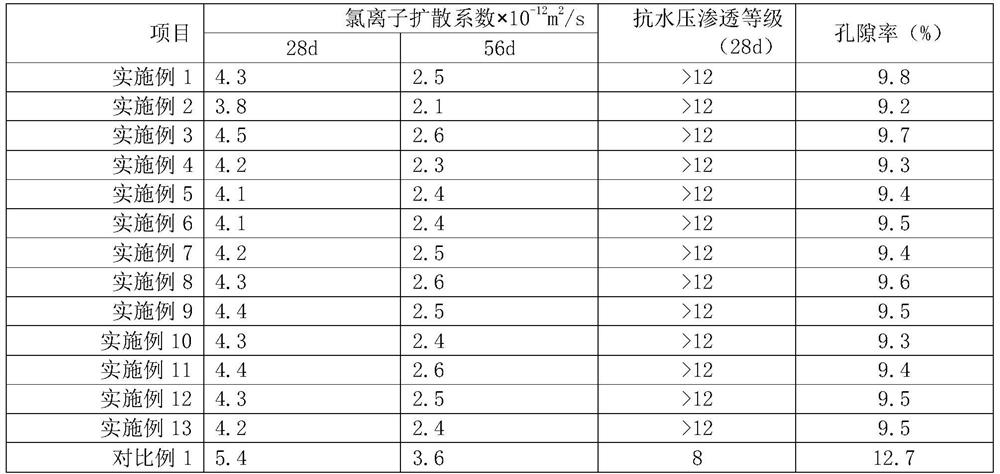

Examples

Embodiment 1

[0039] A construction waste regenerated concrete. The preparation raw materials include 65 parts of fly ash, 25 parts of stone powder, 350 parts of recycled coarse aggregate, 320 parts of recycled fine aggregate, 28 parts of early strength agent, polycarboxylate 0.5 part of water agent, 3 parts of fatty alcohol sulfonate, 2 parts of reinforcing component, 0.2 part of sodium gluconate; among them, the regenerated coarse aggregate is obtained by crushing and screening waste bricks, and the regenerated fine aggregate is obtained by crushing waste concrete Screened; the early strength agent is a mixture of sodium sulfate and triethanolamine 1:1.5; the reinforcing component is basalt fiber, polypropylene mesh fiber, metakaolin, and CABR-MS605 rust inhibitor 1:1.1:1.2:0.2 mixture.

Embodiment 2

[0041] A construction waste regenerated concrete, prepared according to parts by weight, the preparation raw materials include 74 parts of fly ash, 28 parts of stone powder, 375 parts of recycled coarse aggregate, 345 parts of recycled fine aggregate, 32 parts of early strength agent, polycarboxylic acid reducing 0.9 parts of water agent, 4 parts of fatty alcohol sulfonate, 5 parts of reinforcing components, and 0.5 parts of sodium gluconate; among them, the recycled coarse aggregate is obtained by crushing and screening waste bricks, and the recycled fine aggregate is obtained by crushing waste concrete Screened; the early strength agent is a mixture of sodium sulfate and triethanolamine 1:1.6; the reinforcing component is basalt fiber, polypropylene mesh fiber, metakaolin, and CABR-MS605 rust inhibitor 1:1.5:1.5:0.6 mixture.

Embodiment 3

[0043] A construction waste regenerated concrete, prepared according to parts by weight, the preparation raw materials include 85 parts of fly ash, 34 parts of stone powder, 390 parts of recycled coarse aggregate, 370 parts of recycled fine aggregate, 40 parts of early strength agent, polycarboxylic acid reducing 1.3 parts of water agent, 5 parts of fatty alcohol sulfonate, 7 parts of reinforcing components, and 0.8 parts of sodium gluconate; among them, the recycled coarse aggregate is obtained by crushing and screening waste bricks, and the recycled fine aggregate is obtained by crushing waste concrete Screened; the early strength agent is a mixture of sodium sulfate and triethanolamine 1:1.8; the reinforcing component is basalt fiber, polypropylene mesh fiber, metakaolin, and CABR-MS605 rust inhibitor 1:1.9:1.7:0.9 mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com