A kind of high-strength boron nitride ceramic and its preparation method

A boron nitride, high-strength technology, applied in the field of high-strength boron nitride ceramics and its preparation, can solve the problems of poor mechanical properties of hexagonal boron nitride ceramics, reduced high-temperature performance, weak van der Waals force, etc., and achieve microstructure The effect of uniform structure distribution, high density and strength, and consistent grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a high-strength boron nitride ceramic in this embodiment comprises the following steps:

[0032] A) Charging: Weigh 2g of single particle size nano cubic boron nitride powder, the particle size of single particle size nano cubic boron nitride powder is 50nm, pre-press molding, pre-press molding is two-way pressure, the size of the pressure 10MPa, put the pre-compacted preform into a sintering mold, the sintering mold is a graphite mold, and the precompact and the graphite mold are separated by graphite paper;

[0033] B) Sintering: Put the pre-compact in step A) together with the sintering mold into the spark plasma sintering equipment for sintering. The sintering method is spark plasma sintering. The sintering step is to apply a pre-pressure first, the pre-pressure is 10MPa, and vacuum to a vacuum degree higher than 1×10 -1 After Pa, the sintering pressure is applied. The sintering pressure is 30MPa. After the sintering pressure is stable, the ...

Embodiment 2

[0039] The manufacturing method of a high-strength boron nitride ceramic in this embodiment has similar process steps to that of Example 1, and the specific process parameters different from that of Example 1 are shown in column 2 of Example 1 in Table 1.

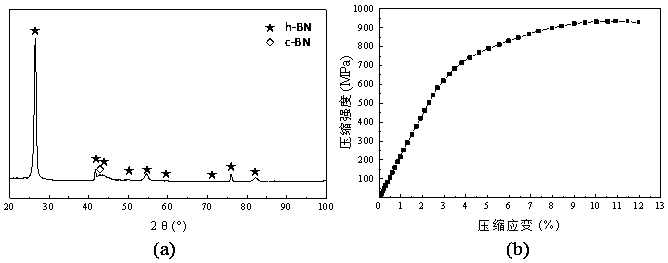

[0040] The high-strength boron nitride ceramic prepared by the preparation method of the high-strength boron nitride ceramic in this embodiment is an opaque block, such as figure 2 The X-ray diffraction spectrum shown in (a), the high-strength boron nitride ceramic block is a nano-polycrystalline block composed of hexagonal boron nitride (hBN) and a small amount of cubic boron nitride (cBN), such as figure 2 As shown in (b), the compressive strength of the high-strength boron nitride ceramic block is 820MPa, and the compressive strain is 11%.

Embodiment 3

[0042]A method for preparing a high-strength boron nitride ceramic in this embodiment has similar process steps to that of Example 1, and the specific process parameters different from that of Example 1 are shown in column 3 of Example 1 in Table 1.

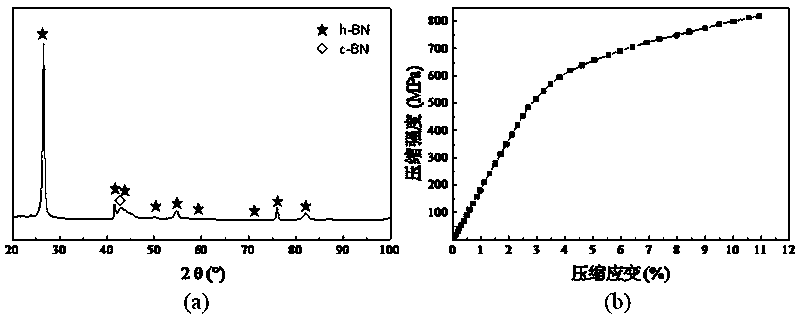

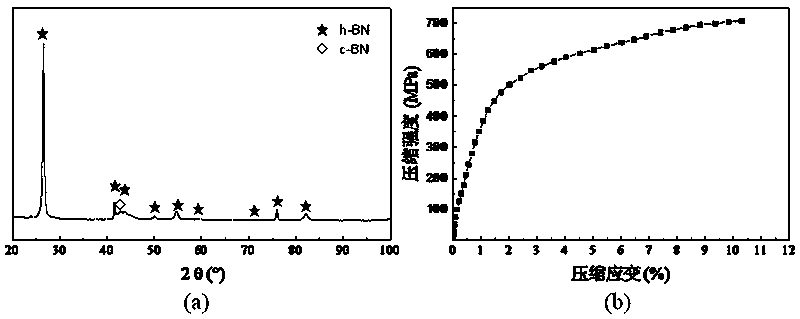

[0043] The high-strength boron nitride ceramic prepared by the preparation method of the high-strength boron nitride ceramic in this embodiment is an opaque block, such as image 3 The X-ray diffraction spectrum shown in (a), the high-strength boron nitride ceramic block is a nano-polycrystalline block composed of hexagonal boron nitride (hBN) and a small amount of cubic boron nitride (cBN), such as image 3 As shown in (b), the compressive strength of the high-strength boron nitride ceramic block is 707MPa, and the compressive strain is 10.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com