Method for preparing isocyanate with low chloride content

A technology of isocyanate and isocyanate solution, which is applied in the purification/separation of isocyanate derivatives, organic chemistry and other directions, can solve the problems of uneconomical, low chlorinated isocyanate derivatives, and complicated processes, and achieves improved reactivity and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

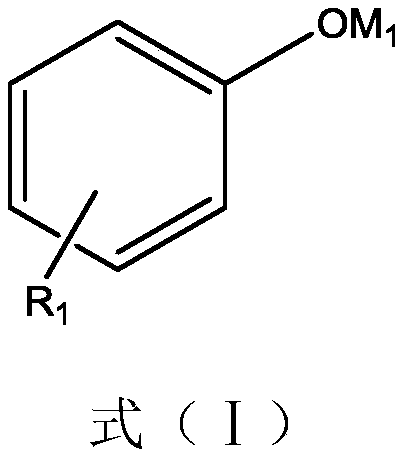

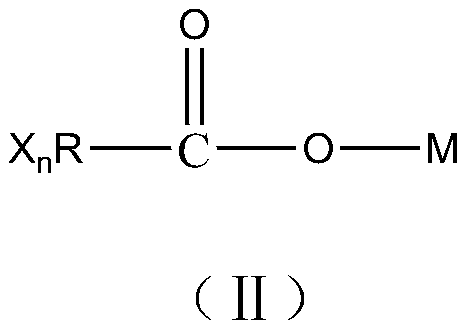

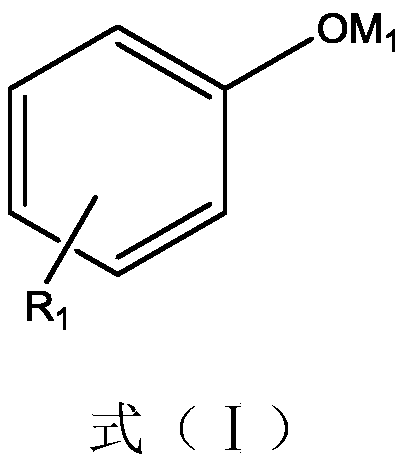

Method used

Image

Examples

Embodiment 1

[0053] 200g hexamethylene diisocyanate in N 2 Under protection, add 200g of compound solvent (the mass ratio of dichloroethane to dimethylformamide is 2:1), add aluminum trichloride after mixing to adjust the pH value to 4, weigh phenol sodium salt and 2- Add 2 g of sodium chlorobenzyl formate powder into the solution (the mass ratio of sodium phenolate to sodium chlorobenzyl formate is 2:1), heat to 60°C, react for 180 minutes and cool to room temperature, filter to remove impurities, and heat the filtrate to Nitrogen gas is passed at 100°C for stripping, and vacuum distillation is carried out after stripping. The absolute pressure of the control system is at 1kpa, and the temperature of the tower kettle is at 145°C to extract isocyanate with low chlorine content.

Embodiment 2

[0055] 200g dicyclohexylmethane diisocyanate in N 2 Under protection, add 400g of compound solvent (the mass ratio of dichloroethane to dimethylformamide is 3:1), add aluminum trichloride after mixing to adjust the pH value to 6, weigh phenol potassium salt and 2- Add 6 g of sodium chlorobenzyl formate powder into the solution (the mass ratio of potassium phenolate and sodium chlorobenzyl formate is 3:1), heat to 80°C, react for 120 minutes and cool to room temperature, filter to remove impurities, and heat the filtrate to 100 Nitrogen at ℃ for stripping, vacuum distillation after stripping, control system absolute pressure at 1kpa, tower kettle temperature at 145°C, to extract isocyanate with low chlorine content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com