Cyclodextrin modified composite organic solvent nanofiltration membrane and preparation method thereof

A compound organic solvent and cyclodextrin technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor selectivity, unsuitable alkane solvent, non-polar solvent without flux, etc., to achieve The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The polyacrylonitrile ultrafiltration membrane with a molecular weight cut off of 10,000 was submerged to 2.0 mol. L -1 Sodium hydroxide aqueous solution, submerged at 50° C. for 1 hour, then taken out and fully washed with deionized water at room temperature to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane.

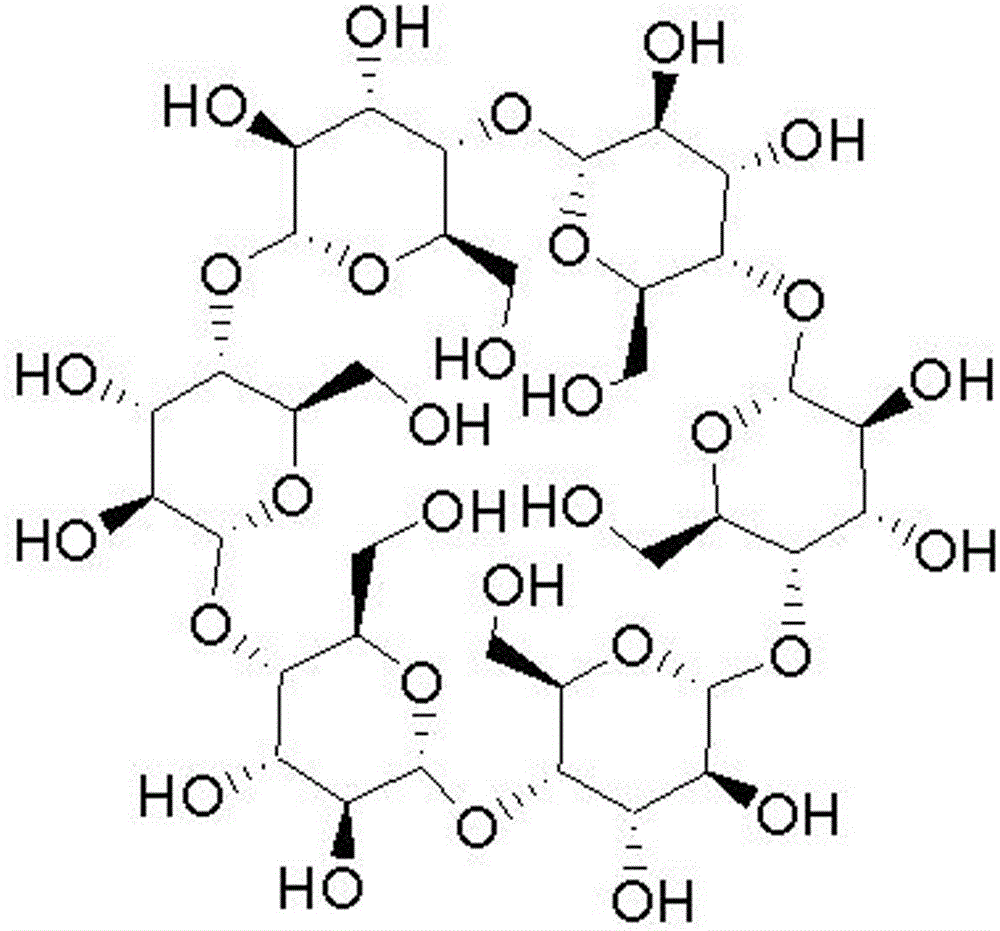

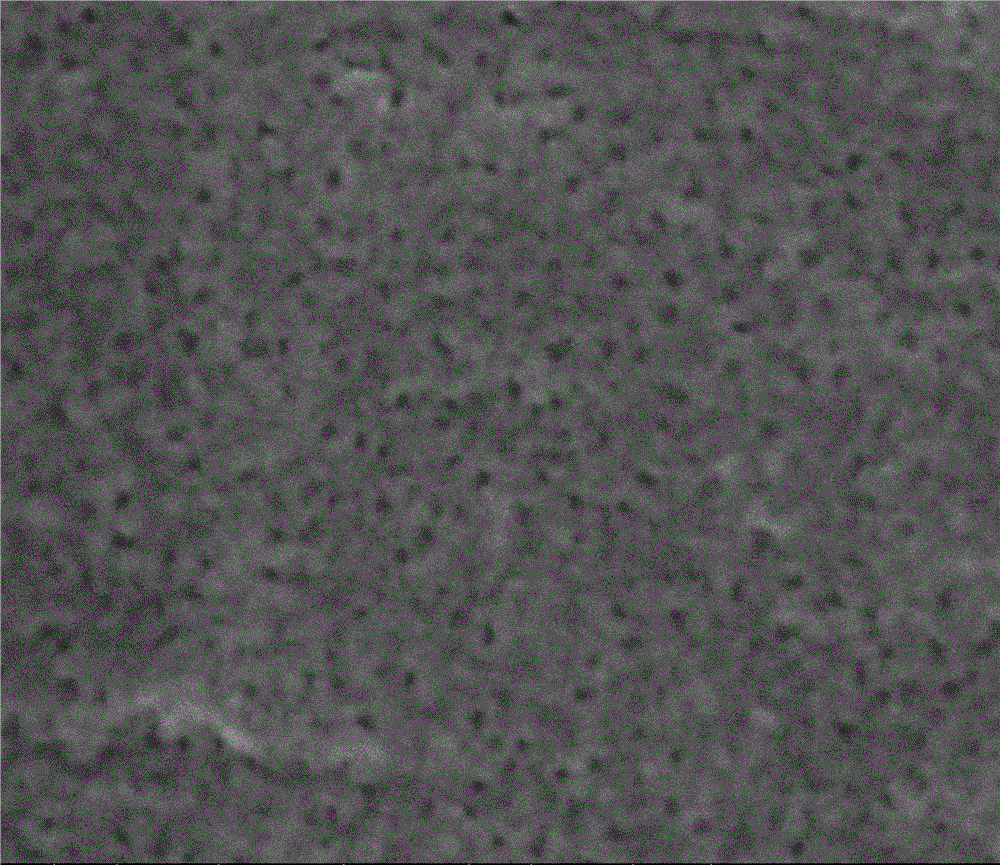

[0027] Add α-cyclodextrin to deionized water, and ultrasonically treat it at room temperature for 1 h; then add piperazine to the above-mentioned cyclodextrin aqueous solution, and continue ultrasonic stirring for 1 h to obtain an aqueous phase solution, wherein the amount of piperazine added is 2% of the weight of the solution. 3%, and the amount of α-cyclodextrin added is 0.03% of the solution weight. Cast the obtained aqueous phase solution on a hydrolyzed polyacrylonitrile ultrafiltration membrane, soak at room temperature for 20 minutes, remove excess solution on the surface of the membrane, and dry at room temperature to remove water from t...

Embodiment 2

[0030] Immerse the polyacrylonitrile ultrafiltration membrane with a molecular weight cut off of 100,000 to 1.0 mol. L -1 Sodium hydroxide aqueous solution, submerged at 50° C. for 1 hour, then taken out and fully washed with deionized water at room temperature to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane.

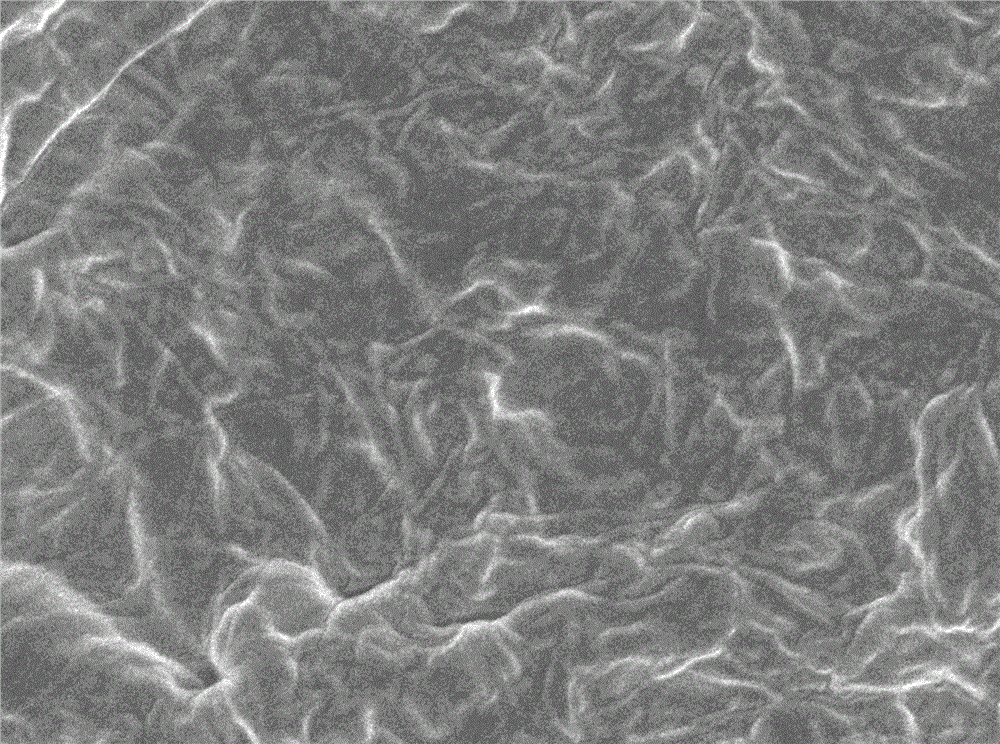

[0031] Add β-cyclodextrin to deionized water, and ultrasonically treat it at room temperature for 2 h; then add polyethyleneimine to the above cyclodextrin aqueous solution, and continue ultrasonic stirring for 1 hour to obtain an aqueous phase solution, in which water: polyethyleneimine :β-cyclodextrin=25:1:0.03 (mass ratio). Cast the obtained casting solution on a hydrolyzed polyacrylonitrile ultrafiltration membrane, soak at room temperature for 10 minutes, remove excess solution on the surface of the membrane, and dry at room temperature to remove water from the membrane surface; then use 4% by mass of trimesoyl chloride The n-hexane solution obt...

Embodiment 3

[0034]A polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 200,000 was selected, and the membrane was prepared according to the method and steps described in Example 2, but the cyclodextrin dissolved in the aqueous solution was γ-cyclodextrin, and its consumption was the same as in Example 2. The film produced is denoted as γ-cyclodextrin film.

[0035] The area swelling degree of γ-cyclodextrin film in isopropanol, ethyl acetate, butanone, n-heptane and toluene is less than 4.5%. Thermogravimetric analysis (TGA) shows that the initial degradation temperature of the film is 328.1°C, that is, the film has Good thermal stability. At room temperature and 1 MPa, the rejection rate of γ-cyclodextrin membrane to PEG4000 was higher than 90%; the fluxes of γ-cyclodextrin membrane to isopropanol, ethyl acetate, butanone and n-heptane were 44.6, 27.6, 24.1 and 48.1 L. m -2 ﹒ h -1 , the flux of toluene reaches 25.6 L. m -2 ﹒ h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com