Preparation method of anti-wrinkle antibacterial fabric

An antibacterial and fabric technology, applied in enzyme/microbial biochemical treatment, textile, biochemical fiber treatment, etc., can solve problems such as poor anti-wrinkle performance and antibacterial performance, poor antibacterial fabric effect, shortened service life of fabrics, etc., to achieve slow down Aging speed, good UV shielding performance, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

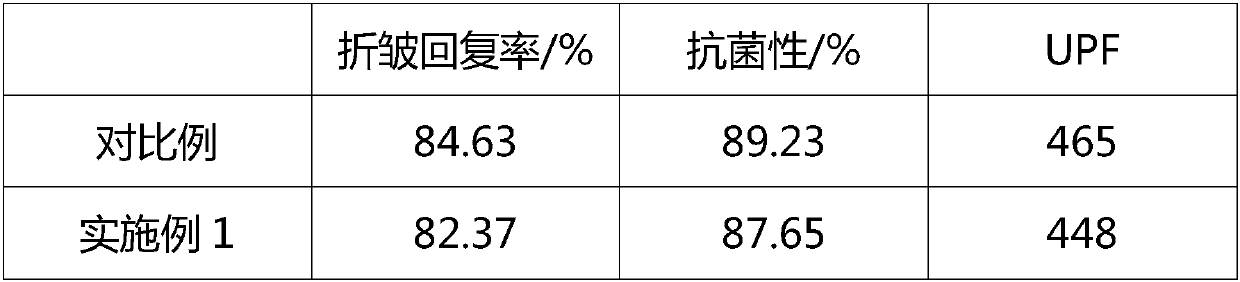

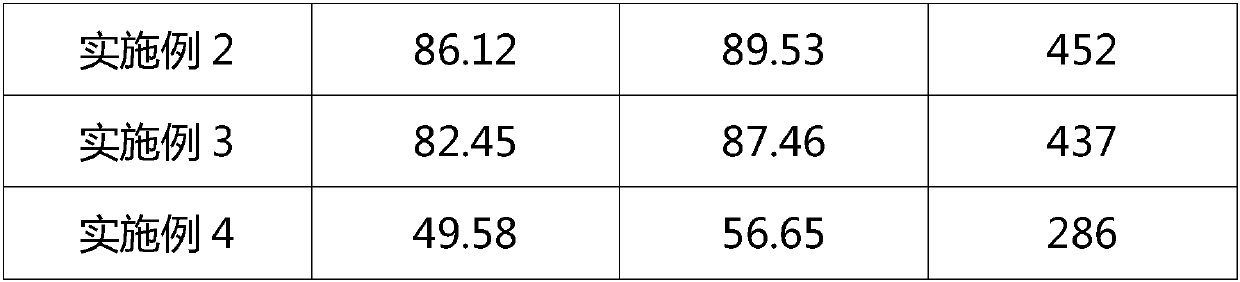

Examples

Embodiment 1

[0030] A preparation method of anti-wrinkle antibacterial fabric, comprising the following steps:

[0031] S1. Accurately weigh 36 parts of kapok fiber and 20 parts of apocynum fiber by weight, and then soak the two in the biological enzyme soaking solution with a temperature of 30°C for 4 hours, and at low speed every 30 minutes during the soaking process Stir for 3 minutes;

[0032] S2, after kapok fiber and apocynum fiber are pulled out, soak in the ethanol solution that temperature is 45 ℃, then add 5 parts of nano-mixed fine powder thereinto, and add 0.5 part of sodium dioctyl succinate sulfonate, After ultrasonic dispersion for 5 minutes, add 2 parts of azobisisopropylimidazoline hydrochloride, 3 parts of hexamethyldisiloxane and 0.7 parts of sodium dioctyl succinic acid sulfonate, and ultrasonically disperse for 10 minutes , and then stand still at room temperature for 5 hours and then roll the liquid;

[0033] S3. Rinse the kapok fiber and apocynum fiber with clean w...

Embodiment 2

[0045] A preparation method of anti-wrinkle antibacterial fabric, comprising the following steps:

[0046] S1. Accurately weigh 40 parts of kapok fiber and 22 parts of apocynum fiber by weight, and then soak the two in the biological enzyme soaking solution with a temperature of 32 ° C for 5 hours, and at low speed every 35 minutes during the soaking process Stir for 5 minutes;

[0047] S2, after kapok fiber and apocynum fiber are pulled out, soak in the ethanol solution that temperature is 50 ℃, then add 7 parts of nano-mixed fine powder thereinto, and add 0.7 part of sodium dioctyl succinate sulfonate, After ultrasonic dispersion for 6 minutes, add 2.5 parts of azobisisopropyl imidazoline hydrochloride, 3.5 parts of hexamethyldisiloxane and 0.9 parts of sodium dioctyl succinic acid sulfonate, and ultrasonically disperse for 15 minutes , and then stand at room temperature for 6 hours and then roll the liquid;

[0048] S3. Rinse the kapok fiber and apocynum fiber with clean ...

Embodiment 3

[0060] A preparation method of anti-wrinkle antibacterial fabric, comprising the following steps:

[0061] S1. Accurately weigh 43 parts of kapok fiber and 24 parts of apocynum fiber by weight, and then soak the two in the biological enzyme soaking solution with a temperature of 34 ° C. The soaking time is 7 hours. During the soaking process, every 38 minutes at a low speed Stir for 7 minutes;

[0062] S2, after kapok fiber and apocynum fiber are pulled out, soak in the ethanol solution that temperature is 52 ℃, then add 8 parts of nano-mixed fine powder thereinto, and add 0.8 part of sodium dioctyl sulfosuccinate, After ultrasonic dispersion for 8 minutes, add 3.5 parts of azobisisopropylimidazoline hydrochloride, 4.5 parts of hexamethyldisiloxane and 1.0 part of sodium dioctyl succinic acid sulfonate, and ultrasonically disperse for 18 minutes , and then stand at room temperature for 7 hours and then roll the liquid;

[0063] S3. Rinse the kapok fiber and apocynum fiber wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com