Full air volume cooling system and method for coal face

A coal mining face and air volume technology, applied in mining equipment, earthwork drilling, mine/tunnel ventilation, etc., can solve problems such as high operating costs, poor cooling effect, and potential safety hazards, and reduce investment and operation cost, improve the effect of cooling and dehumidification, and reduce the effect of maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

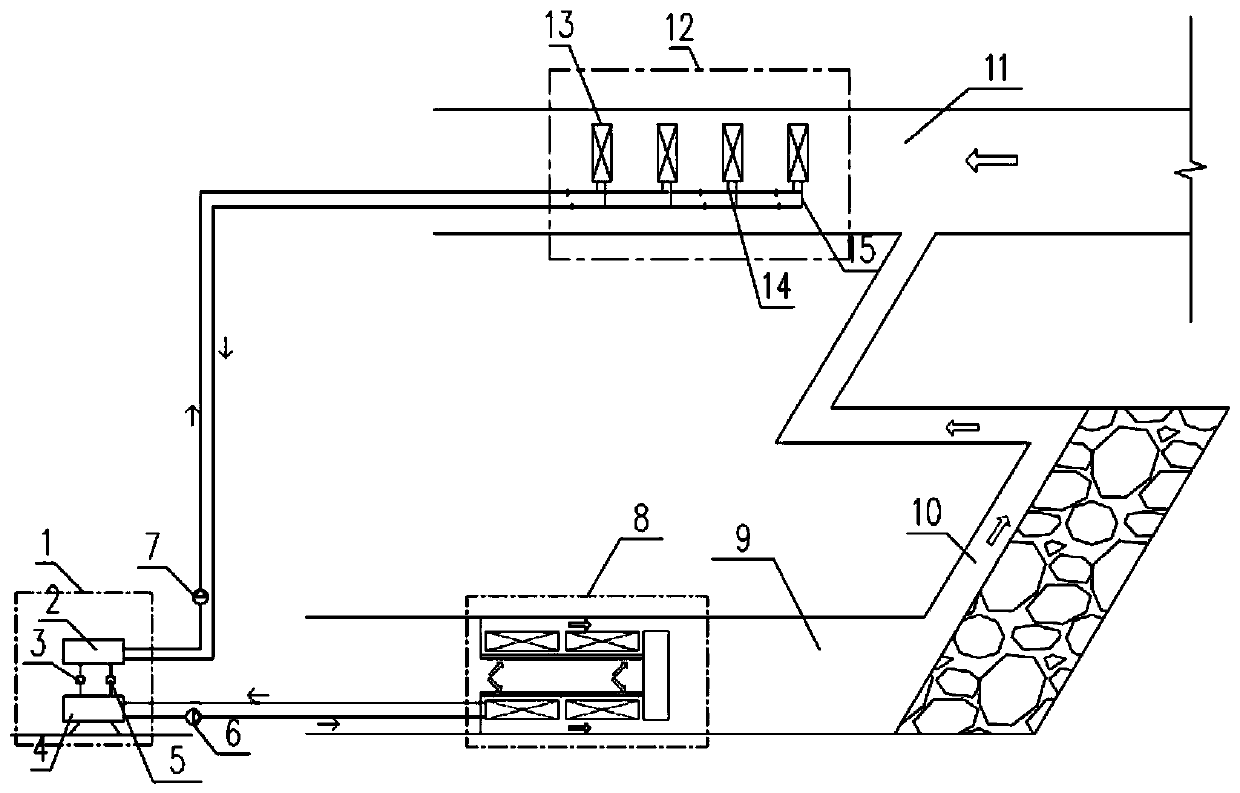

[0034] Such as Figure 1~2 As shown, the coal mining face full air volume cooling system of the present invention includes a chiller 1, an air inlet air cooling device 8 and a return air cooling device 12; the chiller 1 includes a condenser 2, a compressor 3, and an evaporator 4 and a throttle valve 5, the condenser 2 and the evaporator 4 both include two passages, the first passage of the condenser 2, the compressor 3, the first passage of the evaporator 4 and the throttle valve 5 are connected in sequence to form a loop, The inlet air cooling device 8 and the return air cooling device 12 are respectively connected with the second passage of the evaporator 4 of the chiller 1 and the second passage of the condenser 2;

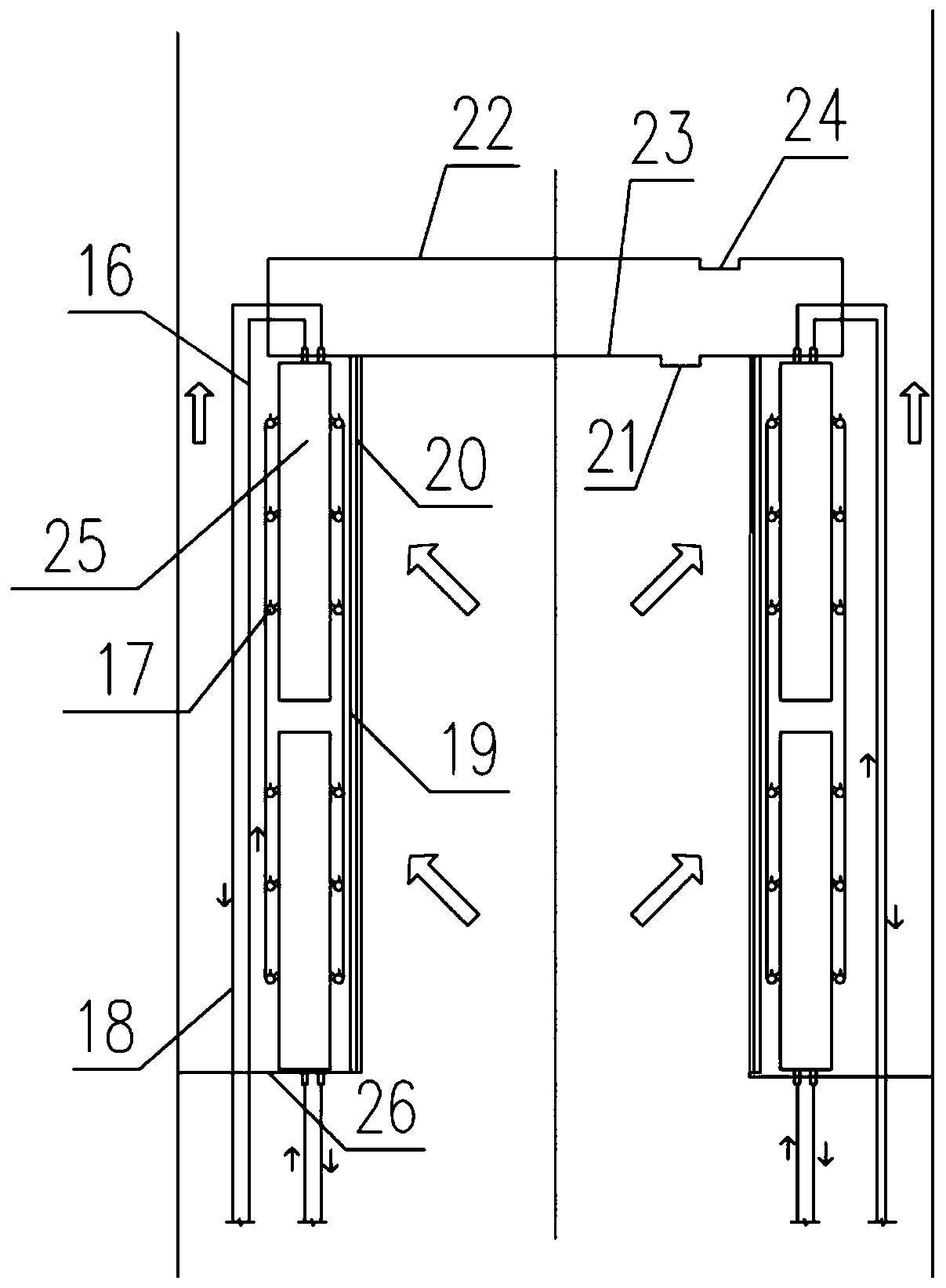

[0035]The inlet air cooling device 8 is installed in the air inlet lane 9 of the coal mining face, and the inlet air cooling device 8 includes a rear damper 22, a rear damper 24 located on the rear damper 22, and a front damper along the direction away from the...

Embodiment 2

[0048] A coal mining face has a width of 200m, an average section perimeter of 14m, an average original rock temperature of 40°C, and an unstable heat transfer coefficient of surrounding rock of 0.003856kW / (m 2 ℃), the air supply volume of the mining face is 1500m 3 / min, before cooling measures are taken, it is assumed that the dry bulb temperature of the coal mining face is 30°C, the relative humidity is 80%, the dry bulb temperature of the return air flow is 36°C, and the relative humidity is 100%; after taking cooling measures, The dry bulb temperature of the wind stream after treatment is 26°C and the relative humidity is 90%. The calculated cooling load of the working face is 2000kW. According to the method of embodiment 1, the full air volume cooling system and method of the coal mining face are installed, wherein the number of recoolers is 15, installed in the total air return lane; the number of air coolers is 8, installed on average in the mining area On both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com