Application of organic free radicals and derivatives thereof in photovoltaic devices

A technology of photovoltaic devices and free radicals, which is applied in the application field of organic free radicals and their derivatives in photovoltaic devices, can solve the problems of restricting the development and application of organic free radical materials, and the narrow application range of organic free radicals, and achieves widespread acceptance. Body selection, widening applications, and the effect of expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

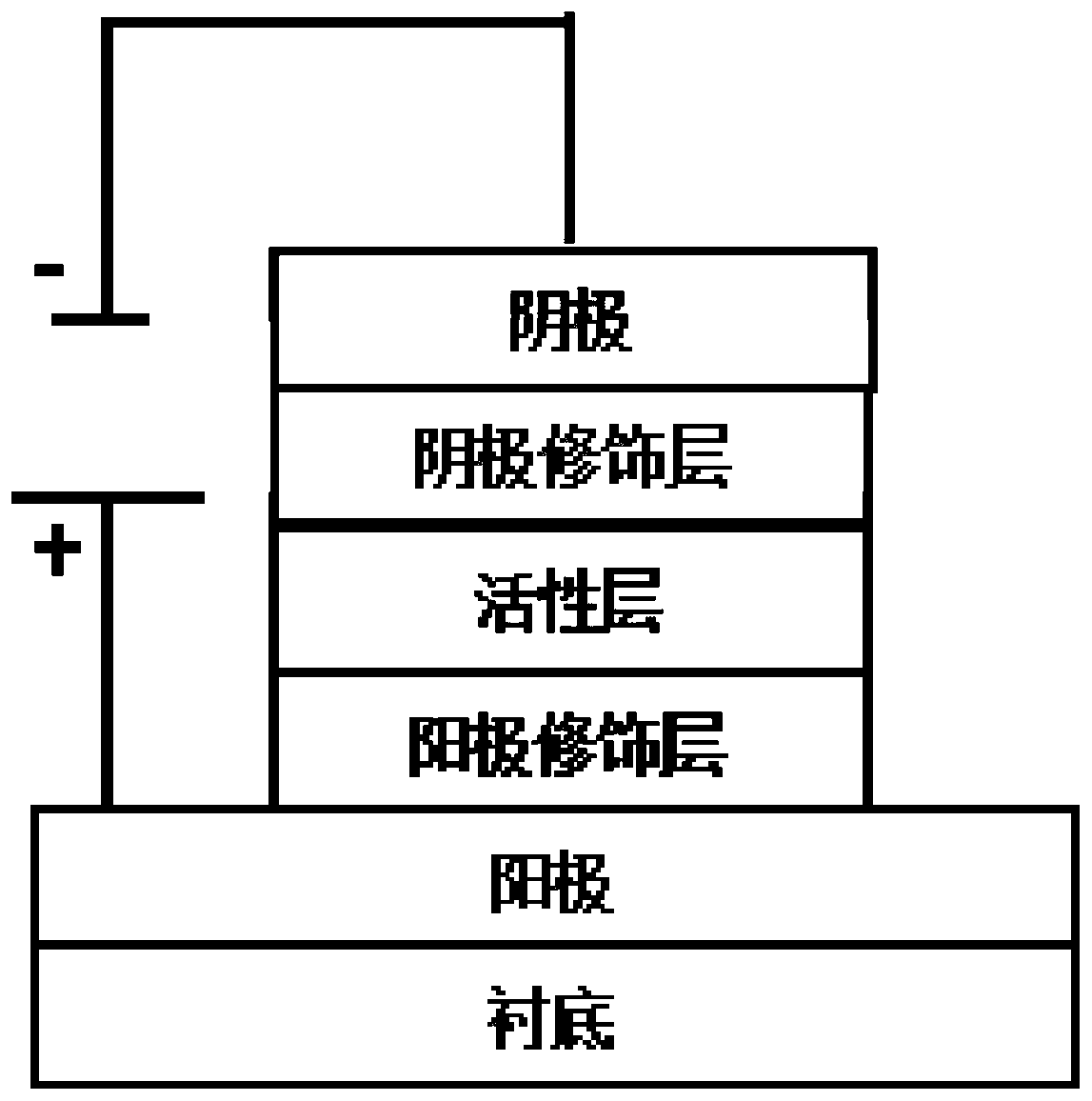

[0033] Embodiment 1 Preparation of upright organic / polymer photovoltaic device

[0034] The ITO conductive glass, with a square resistance of ~20 ohms / square meter, was pre-cut into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, and then place it in a constant temperature oven for later use after purging with nitrogen. Before use, clean ITO sheets were bombarded with plasma in an oxygen plasma etcher for 10 minutes. On the anode ITO conductive glass, use PEDOT:PSS aqueous dispersion (about 1.3-1.7%, purchased from Xi'an Baolight Optoelectronics Technology Co., Ltd.) as the anode modification layer, and pass through a homogenizer (KW-4A) at high speed (3200 rpm) per minute) spin-coating, the thickness is determined by the concentration of the solution and the rotational speed, and is measured and monitored with a probe-type surface profiler (Dektak-XT type of Bruker ...

Embodiment 2

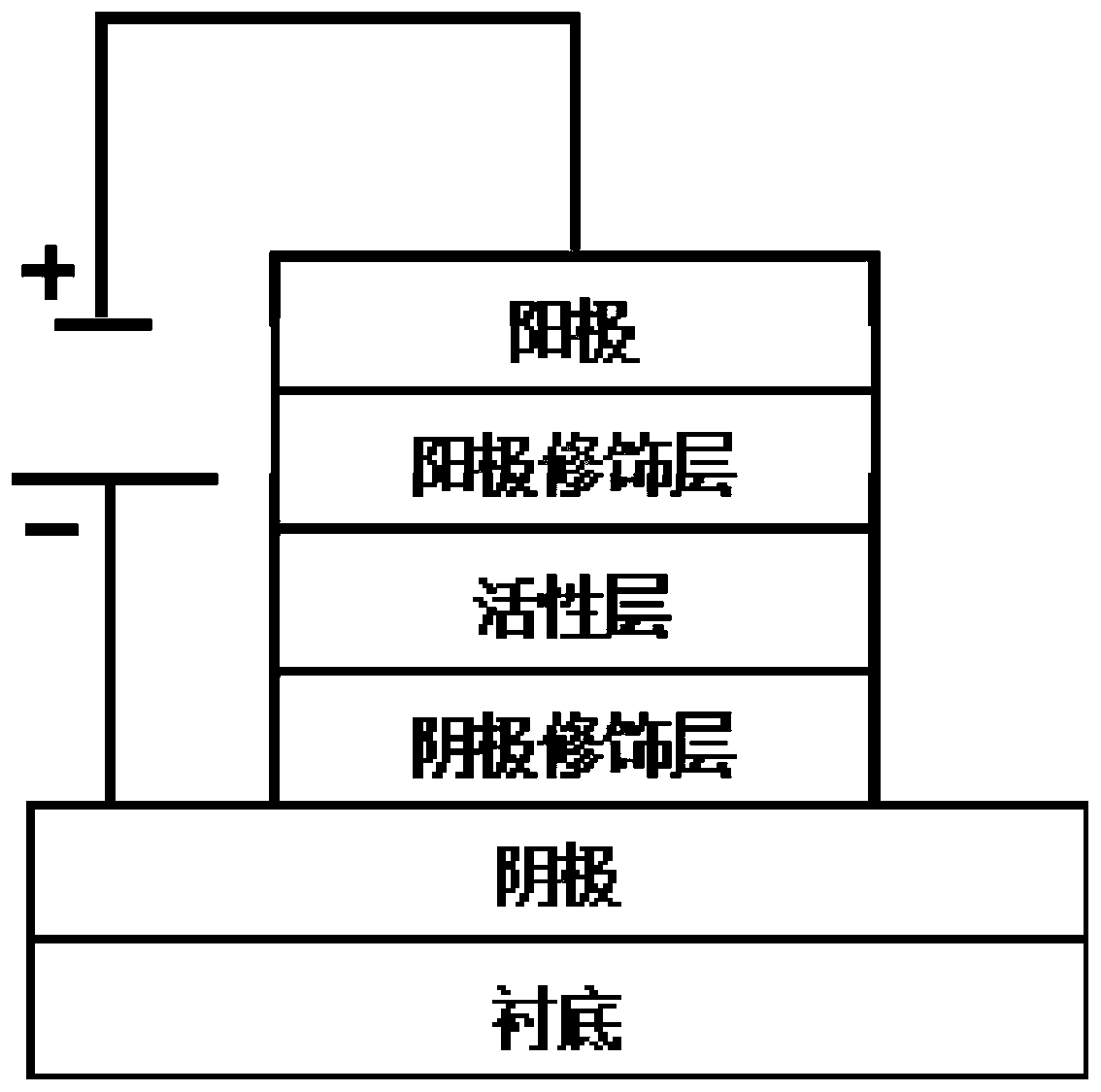

[0039] Embodiment 2 Preparation of inverted organic / polymer photovoltaic device

[0040] The ITO conductive glass, with a square resistance of ~20 ohms / square meter, was pre-cut into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, and then place it in a constant temperature oven for later use after purging with nitrogen. Before use, clean ITO sheets were bombarded with plasma in an oxygen plasma etcher for 15 minutes. First prepare the composite cathode layer (ITO / ZnO) of ITO / ZnO: spin-coat (rotating speed 3000 revolutions per minute) one deck zinc acetate solution (concentration 100 mg per milliliter) on the ITO conductive glass, heat treatment at 200 degrees Celsius for 1 hour, A layer of zinc oxide is formed as a cathode modification layer.

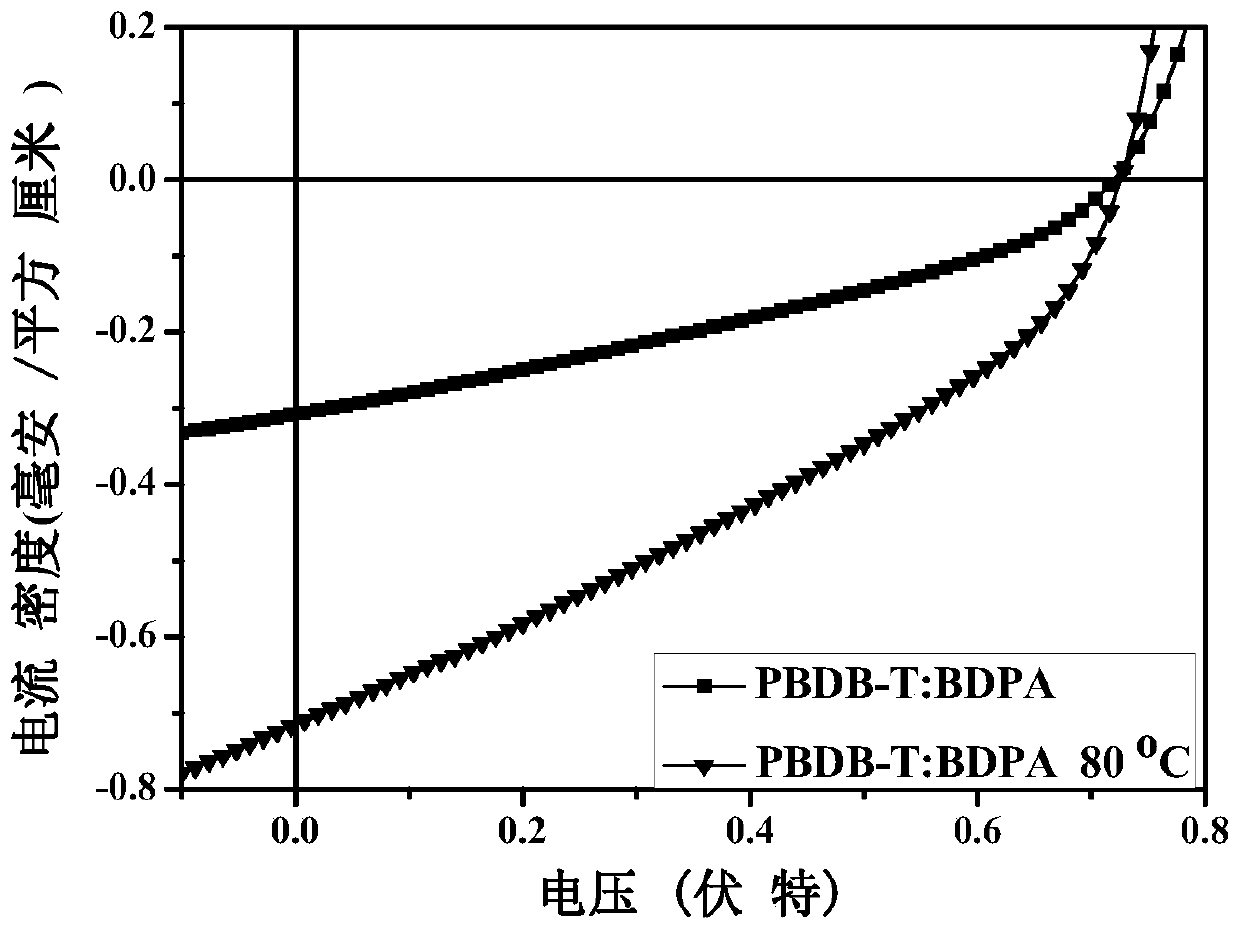

[0041] After the conjugated polymer donor material PBDB-T was weighed in a clean bottle, it was transferred to a special g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com