Forming process of anti-corrosion concrete prefabricated square pile

A molding process and concrete technology, which is applied in the direction of manufacturing tools, pretreatment control, ceramic molding machines, etc., can solve the problems of poor additive effects and difficulty in mixing uniformly, so as to inhibit expansion damage, delay erosion damage, and increase compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

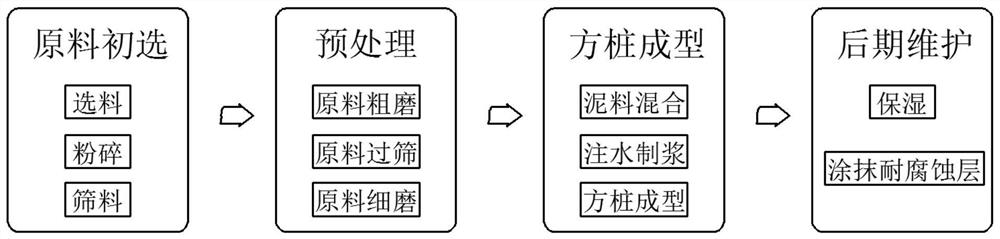

[0045] see figure 1 , S1, primary selection of raw materials, select additives with appropriate size and good appearance, fly ash blocks and mineral powder blocks, and crush the additive blocks, crush the additives into fragments of similar size, and sieve the fragments , to sieve the oversized fragments, and re-crunch until the fragment size reaches the standard. In the primary selection of S1 raw materials, it is necessary to use dry additive blocks. Before the primary selection, the additives need to be dried to facilitate subsequent crushing and grinding. Fine, so that the fragments and fine powder are not easy to bond together;

[0046] S2, pretreatment, separate the different raw materials for rough grinding, then sieve the powder obtained from the coarse grinding to obtain coarse powder, then mix the coarse powder of different raw materials and then finely grind to obtain the additive fine powder mixed with raw materials. In the S2 pretreatment, ball milling is used in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com