A kind of heat-resistant PVC laminated board and preparation method thereof

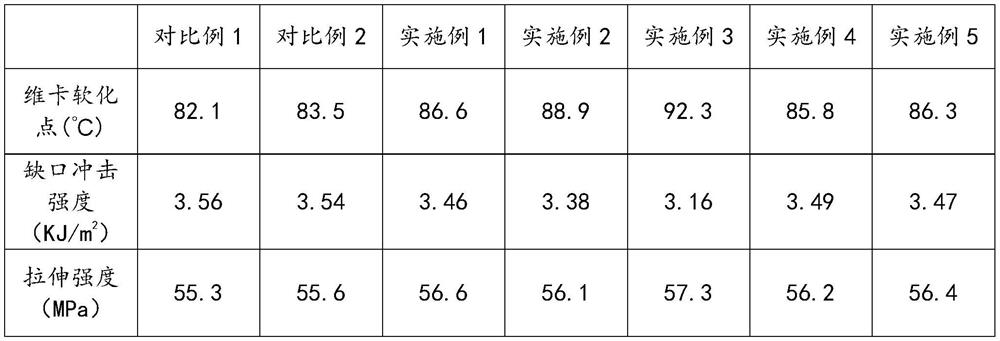

A technology for laminates and PVC resin powder, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem that the heat resistance can not be reliably used for long-term use, and achieve scientific and reasonable raw material formulations. Meet the requirements of the national standard, the effect of little change in impact strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. The heat-resistant PVC laminate of this embodiment is made of the following raw materials in parts by weight: 100 parts of PVC resin powder (SG-5 resin produced by Shandong Qilu Petrochemical), 4.1 parts of stabilizer (calcium-zinc composite thermally stable agent), lubricant (PE wax) 0.7 parts, filler (1250 mesh calcium carbonate) 15 parts, heat-resistant agent 5 parts.

[0014] The heat-resistant agent is prepared from styrene, oleic acid and acrylonitrile by suspension polymerization. The preparation method of the heat-resistant agent is as follows: add styrene to oleic acid and keep stirring for 2 hours, heat to 88°C, add acrylonitrile several times, keep stirring at 88°C for 2 hours; then cool to below 40°C, wash, It can be filtered and dried; the volume ratio of oleic acid to styrene is 4:1; the total mass of acrylonitrile added is 8% of the mass of styrene.

[0015] 2. The preparation method of the heat-resistant PVC laminate is as follows: add all the raw ma...

Embodiment 2

[0017] 1. The heat-resistant PVC laminate of the present embodiment is made of the following raw materials in parts by weight: 100 parts of PVC resin powder (SG-5 resin produced by Shandong Qilu Petrochemical Co., Ltd.), stabilizer (calcium-zinc composite heat stabilizer) 3.6 parts, 0.6 parts of lubricant (PE wax), 14 parts of filler (1250 mesh calcium carbonate), 10 parts of heat-resistant agent.

[0018] The heat-resistant agent is prepared from styrene, oleic acid and acrylonitrile by suspension polymerization. The preparation method of the heat-resistant agent is: add styrene to oleic acid and continue to stir for 30 minutes, heat to 88°C, add acrylonitrile several times, keep stirring at 86°C for 1 hour; then cool to below 40°C, wash, It can be filtered and dried; the volume ratio of oleic acid to styrene is 3:1; the total mass of acrylonitrile added is 5% of the mass of styrene.

[0019] 2. The preparation method of the heat-resistant PVC laminate is as follows: add all...

Embodiment 3

[0021] 1. The heat-resistant PVC laminate of the present embodiment is made of the following raw materials in parts by weight: 100 parts of PVC resin powder (SG-5 resin produced by Shandong Qilu Petrochemical Co., Ltd.), stabilizer (calcium-zinc composite heat stabilizer) 3.6 parts, 0.6 parts of lubricant (PE wax), 18 parts of filler (clay, silica-alumina carbon black, rubber powder), 15 parts of heat-resistant agent.

[0022] The heat-resistant agent is prepared from styrene, oleic acid and acrylonitrile by suspension polymerization. The preparation method of the heat-resistant agent is as follows: add styrene to oleic acid and continue to stir for 2 hours, heat to 86°C, add acrylonitrile several times, keep stirring at 88°C for 2 hours; then cool to below 40°C, wash, It can be filtered and dried; the volume ratio of oleic acid to styrene is 4:1; the total mass of acrylonitrile added is 8% of the mass of styrene.

[0023] 2. The preparation method of the heat-resistant PVC l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com