Preparation method of high-strength flame retardant building electrical sleeve material

A technology for building electrical and threading pipes, which is applied in the field of preparation of high-strength flame-retardant building electrical threading pipe materials, which can solve the problems of poor pressure resistance and flame retardancy of threading pipes, achieve good physical and mechanical properties, and improve fire resistance Performance, elongation reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

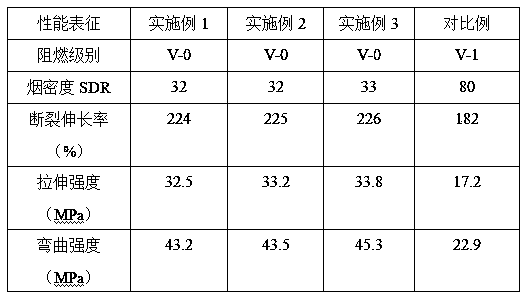

Examples

Embodiment 1

[0032] In parts by weight, weigh 20 parts of polyvinyl chloride, 1 part of chloroprene rubber, 1 part of maleic anhydride, and 0.3 parts of sodium hydride, mix polyvinyl chloride, chloroprene rubber and maleic anhydride in a torque flow In a variable instrument, react at a temperature of 100°C and a speed of 40r / min for 1h to obtain a mixed material. Add polyvinyl chloride to the mixed material, stir for 30min at a speed of 60r / min and a temperature of 60°C, and cool to At room temperature, the main resin is obtained; the mass fraction of 50% magnesium hydroxide solution and kaolin are mixed according to the mass ratio of 5:1, and the stirring speed is 300r / min. Filter to obtain the filter residue, place the filter residue in an oven at 60°C to dry to constant weight, and cool to room temperature to obtain the filler; mix the titanate coupling agent and isopropanol evenly in a mass ratio of 1:5, To obtain the modifier, mix the filler and the modifier at a mass ratio of 1:3, st...

Embodiment 2

[0034] In parts by weight, weigh 25 parts of polyvinyl chloride, 5 parts of neoprene, 2 parts of maleic anhydride, and 0.4 parts of sodium hydride, mix polyvinyl chloride, neoprene and maleic anhydride in a torque rheological In the instrument, react at a temperature of 103°C and a speed of 45r / min for 1.5h to obtain a mixed material. Add polyvinyl chloride to the mixed material, stir for 35in at a speed of 65r / min and a temperature of 65°C, and cool to At room temperature, the main resin is obtained; the mass fraction of 50% magnesium hydroxide solution and kaolin are mixed according to the mass ratio of 5:1, and the stirring speed is 350r / min. Filter to obtain the filter residue, place the filter residue in an oven at 65°C to dry to constant weight, and cool to room temperature to obtain the filler; mix the titanate coupling agent and isopropanol evenly in a mass ratio of 1:5, To obtain the modifier, mix the filler and the modifier at a mass ratio of 1:3, stir at a constant ...

Embodiment 3

[0036] In parts by weight, weigh 30 parts of polyvinyl chloride, 10 parts of neoprene rubber, 3 parts of maleic anhydride, and 0.5 parts of sodium hydride, mix polyvinyl chloride, neoprene rubber and maleic anhydride in a torque flow In a variable instrument, react at a temperature of 105°C and a speed of 50r / min for 2h to obtain a mixed material. Add polyvinyl chloride to the mixed material, stir for 40min at a speed of 70r / min and a temperature of 70°C, and cool to At room temperature, the main resin is obtained; the mass fraction of 50% magnesium hydroxide solution and kaolin are mixed according to the mass ratio of 5:1, and the stirring speed is 400r / min. Filter to obtain the filter residue, place the filter residue in an oven at 70°C to dry to constant weight, and cool to room temperature to obtain the filler; mix the titanate coupling agent and isopropanol evenly at a mass ratio of 1:5, To obtain the modifier, mix the filler and the modifier at a mass ratio of 1:3, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com