Patents

Literature

33results about How to "Improve sunlight resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-wear resistance cable sheath material

ActiveCN103265738AGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsWaxPolypropylene

The invention discloses a high-wear resistance cable sheath material. The high-wear resistance cable sheath material comprises the following raw materials by weight: 90 to 100 parts of chloroprene rubber DCR114, 10 to 20 parts of EPDM 4770R, 15 to 20 parts of nanometer bauxite, 20 to 30 parts of a modification filling material, 8 to 10 parts of dioctyl sebacate, 3 to 4 parts of polypropylene adipate, 4 to 6 parts of acetyl triethyl citrate, 2 to 4 parts of zinc oxide, 6 to 8 parts of chlorinated paraffin, 2 to 3 parts of antimony trioxide, 2 to 4 parts of triphenyl phosphite, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of the promoter CZ and 0.8 to 1 part of sulphur. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

Flame retardant cable sheath material

ActiveCN103265739AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPolymer scienceCompression set

The invention discloses a flame retardant cable sheath material. The flame retardant cable sheath material comprises the following raw materials by weight: 97 to 100 parts of chloroprene rubber SN23, 10 to 15 parts of chlorinated polyethylene, 15 to 20 parts of hydrotalcite, 8 to 10 parts of magnesium carbonate, 18 to 25 parts of a modification filling material, 4 to 5 parts of trioctyl trimellitate, 3 to 4 parts of methylpentachlorostearate, 1 to 2 parts of an anti-aging agent ODA, 1 to 2 parts of a promoter TMTM, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 3 to 4 parts of ethylene bis stearamide, 2 to 4 parts of aluminum tripolyphosphate, 1 to 2 parts of ferrocene, 1 to 2 parts of an anti-oxidant 168 and 1 to 3 parts of benzotriazole. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

Ageing resistant cable sheath material

ActiveCN103242574AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesCross-linkDispersity

The invention discloses an ageing resistant cable sheath material which comprises the following raw materials in parts by weight: 95-101 parts of neoprene A-30, 20-30 parts of nano calcium carbonate, 10-16 parts of modified filler, 6-9 parts of ethylene bis stearamide, 4-6 parts of epoxidized soybean oil, 15-20 parts of chlorinated polyethylene, 2-3 parts of diphenylamine, 10-15 parts of potassium feldspar powder, 2-4 parts of dibasic lead phosphate, 2-3 parts of antioxygen DSTP, 3-5 parts of barium stearate, 0.8-1 part of a cross-linking agent ATC, 0.8-1 part of an accelerant TMTD and 1-2 parts of dipentamethylenethiuram. The prepared ageing resistant cable sheath material has excellent performance, size stability, low shrinking percentage, has strong tensile strength, strong tearing strength, strong resilience force performance and also has good oil resistance, heat resistance, sunlight resistance, ozone resistance, acid / alkali resistance and chemical reagent resistance; and the modified filler has good dispersity and surface tension, can further improve the tensile strength and stress at definite elongation of the cable sheath material and reduce heating and compression set of the cable sheath material, is capable of slowing down the aging speed of the cable sheath material, resisting acid and alkali corrosion and reducing production cost.

Owner:ANHUI KANGLIYA CO LTD

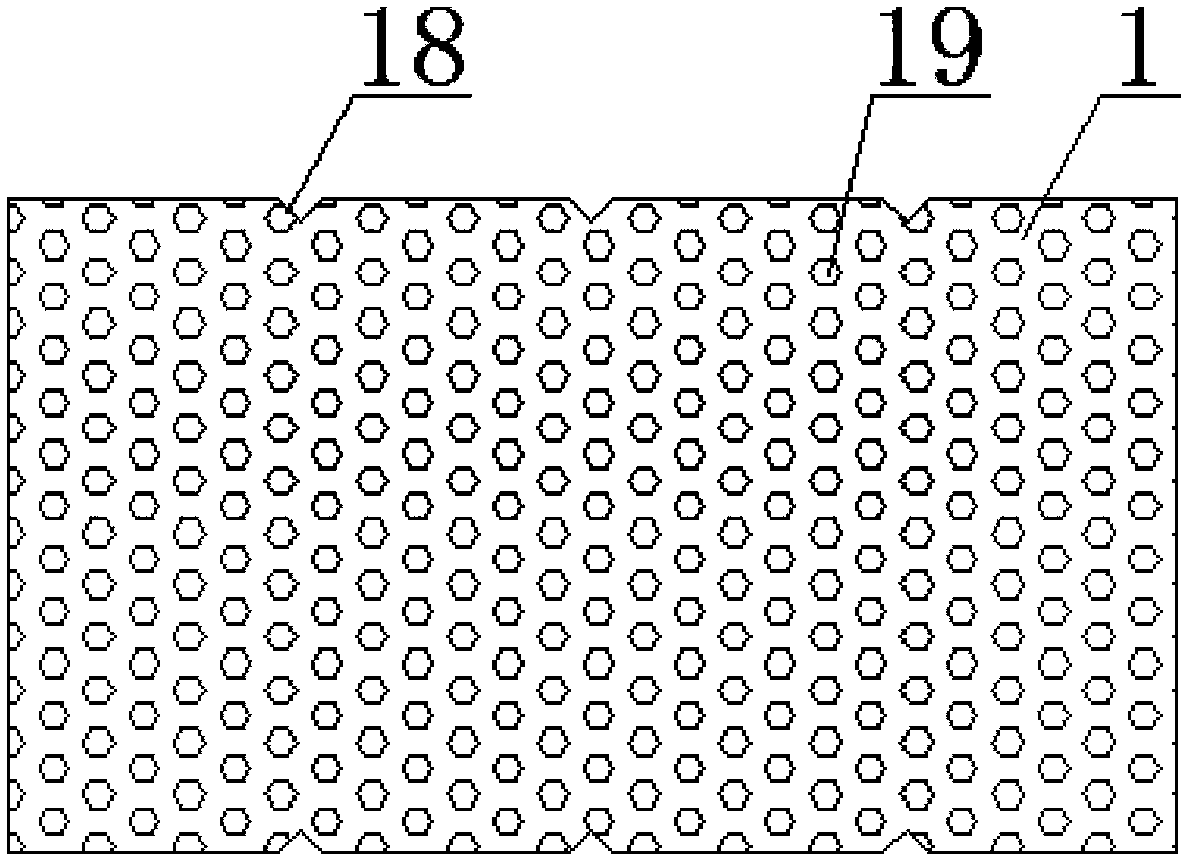

High-speed rail rubber microporous cushion and manufacturing method thereof

InactiveCN105602127AEasy to makeOptimized for shock absorption and lightnessDomestic articlesCushionPlasticizer

The invention discloses a high-speed rail rubber microporous cushion and a manufacturing method thereof. The high-speed rail rubber microporous cushion which is composed of the following components in percentage by mass: 25-50% of synthetic rubber, 16-26% of reinforcing agent, 19-27% of filler, 1.2-2.4% of activator, 10-12% of plasticizer, 2.5-3.5% of foaming agent and 1.0-1.5% of crosslinking agent. The manufacturing method comprises the following steps: (1) compounding; (2) discharging; and (3) vulcanizing. The manufacturing method is simple. The prepared high-speed rail rubber microporous cushion has the advantages of favorable mechanical properties, excellent heat resistance, excellent aging resistance and excellent water resistance, and is suitable to be used under different climatic conditions in different areas.

Owner:HAINING HAIXIANG SHOE MATERIAL

Novel conductive and flame retardant mining tread mix formula of solid tyre and production process

InactiveCN104744750AGood physical and mechanical propertiesImprove heat resistanceSpecial tyresNeopreneMining industry

The invention relates to a novel conductive and flame retardant mining tread mix formula of a solid tyre and a production process. 5-8% of 60-150-mesh swarf is doped into the tread mix, so that the conductive performance and the wear resistance of the tyre are improved. A certain proportion of an environmental flame retardant is added into the tread mix formula, and chloroprene rubber which is excellent in flame retardance and natural rubber which is excellent in comprehensive performance are simultaneously used, so that the problem that the existing mining solid tyre is inflammable and poor in conductivity is solved. The tyre can be widely applied to occasions related to high-temperature combustible environments in mining industry, coal mining industry, metal smelting industry and the like.

Owner:JIANGSU SENGUANG RUBBER PROD

Corrosion-resistant cable sheath material

ActiveCN103360650AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesDispersityCompression set

The invention discloses a corrosion-resistant cable sheath material which is prepared from the following raw materials in parts by weight: 100-102 parts of neoprene CR121, 3-4 parts of aluminum oxide, 4-6 parts of diisobutyl phthalate, 3-4 parts of acetyl triethyl citrate, 1-2 parts of dibasic lead phosphite, 1-2 parts of acetylacetone titanium, 1-2 parts of ethylene glycol dimethacrylate, 2-3 parts of ammonium dihydrogen phosphate, 3-5 parts of ethylene bis stearamide, 25-30 parts of silica powder, 18-24 parts of modified filler, 1-2 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 1-2 parts of anti-aging agent ippd, 3-4 parts of diethanolamine and 0.8-1 part of lead oxide. The modified filler disclosed by the invention has the advantages of favorable dispersity and low surface tension, further enhances the tensile strength and stress at definite elongation of the cable material, lowers the heat generation and permanent compression set, can postpone the aging rate of the cable material, can resist acid / alkali corrosion, and lowers the production cost.

Owner:ANHUI KANGLIYA CO LTD

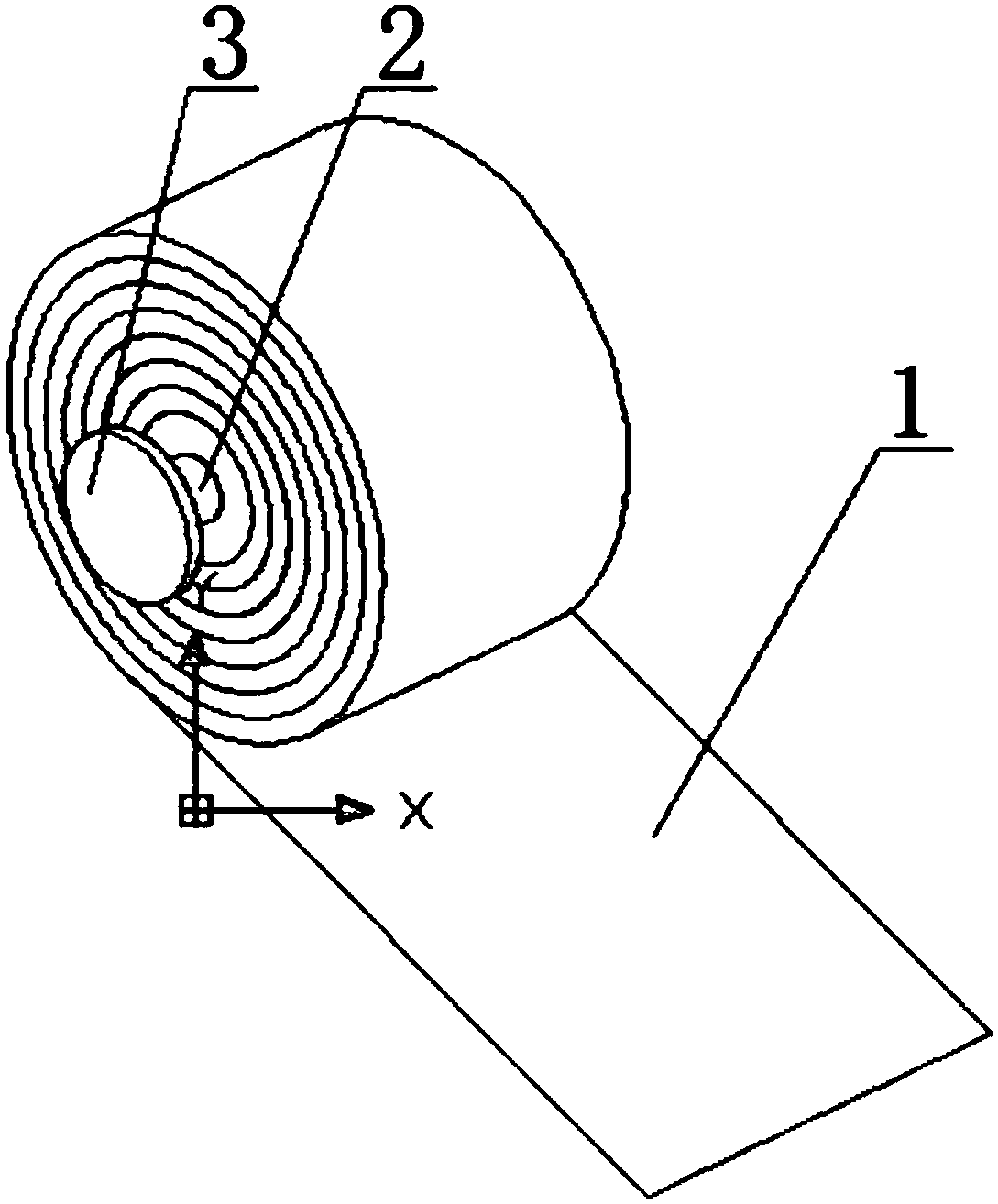

Flexible polyester fiber packing belt and preparation method thereof

The invention particularly relates to a flexible polyester fiber packing belt and a preparation method thereof and belongs to the technical filed of packing materials. The flexible polyester fiber packing belt comprises raw materials in parts by mass as follows: 30-45 parts of PET (polyethylene glycol terephthalate) fibers, 5-8 parts of pectin, 2-6 parts of carbon fibers, 6-10 parts of polyethylene glycol, 0.3-1 part of a fire retardant, 0.5-2 parts of lignin, 1-3 parts of Chinese yam juice, 0.1-0.5 parts of an ultraviolet absorbent UV-531, 0.1-0.5 parts of a light stabilizer 744, 1-4 parts of talcum powder and 0.5-2.5 parts of nanometer titania. The flexible polyester fiber packing belt is high in strength and good in sunlight resistance, and is not prone to pilling.

Owner:SUZHOU DINGLI PACKAGING

Ageing-resisting cable sheath

InactiveCN105504560AGood heat resistanceImproved tear strength and resilience propertiesPlastic/resin/waxes insulatorsInsulated cablesChemistryCarbon black

The invention discloses an ageing-resisting cable sheath. The ageing-resisting cable sheath is prepared from, by weight, 42-52 parts of chlorinated polyethylene, 8-12 parts of epoxidized natural rubber, 1-3 parts of antimonous oxide, 1-4 parts of sulfonamide vulkacit, 15-20 parts of nano calcium carbonate, 3-5 parts of zinc oxide, 1-4 parts of stearic acid, 2-5 parts of ethylene bis stearamide, 0.5-1 part of bis(pentamethylenethiocarbamoyl) hexasulfide, 2-4 parts of cross-linking agent, 2-5 parts of nanosilicon dioxide, 0.5-1 part of pentaerythritol, 2-5 parts of carbon black and 3-7 parts of talcum powder. The ageing-resisting cable sheath is excellent in heat resistance, the tearing strength and resilience force performance are improved, and good heat resistance, inflaming resistance, sunlight resistance and acid and alkali resistance are achieved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

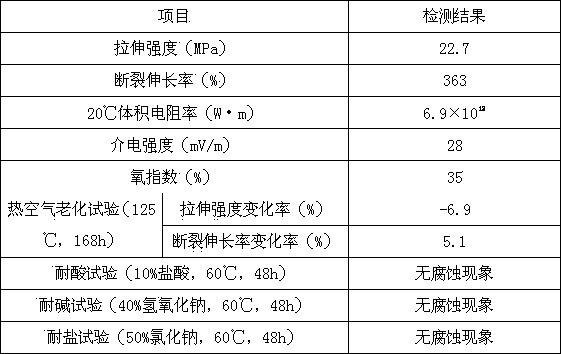

Preparation method of high-strength flame retardant building electrical sleeve material

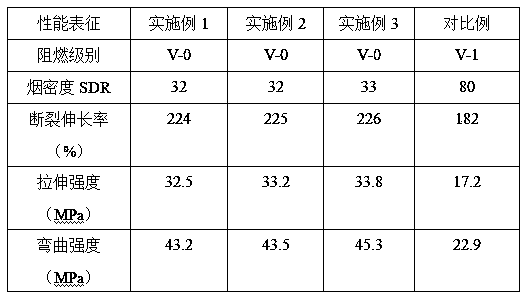

InactiveCN110408146AGood physical and mechanical propertiesImprove sunlight resistancePolymer sciencePolyvinyl chloride

The invention relates to a preparation method of a high-strength flame -retardant building electrical sleeve material, and belongs to the technical field of electrical sleeves. In the invention, chloroprene rubber is used to modify polyvinyl chloride in order to form a main body resin, magnesium hydroxide is intercalated into kaolin in order to form a filler, the filler is surface-treated with a silane coupling agent, and then is compounded with the main body resin, and a dispersant, a stabilizer and other additives are added to prepare the high-strength flame retardant building electrical sleeve material; the chloroprene rubber has a high tensile strength, a high elongation, a reversible crystallinity and a good adhesion; and the chloroprene rubber and polyvinyl chloride form a bicontinuous phase, and form an interpenetrating network structure in the material, the network material greatly deforms and consumes energy under the action of an external force the network structure in orderto achieve the toughening effect, the rubber network can transmit, disperse, buffer and absorb energy under the action of the external force, and the rubber deformation displays a high elongation at break, so the impact resistance of the material is greatly improved.

Owner:陈小强

Dyeable polypropylene modified fiber for satin cloth

InactiveCN112030253AHigh coloring rateFully integratedElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsPolymer scienceOrganotitanium compound

The invention discloses a dyeable polypropylene modified fiber for satin cloth, relates to the technical field of polypropylene modified fibers, and aims to solve the problem of low market value caused by low functionality of an existing dyeable polypropylene modified fiber. The dyeable polypropylene modified fiber is prepared from the following components in percentage by weight: 30%-50% of a fiber body, 10%-15% of silver fibers, 20%-25% of protein fibers and 10%-40% of an additive, wherein the additive is prepared from the following components in percentage by weight: 30%-50% of polypropylene resin, 10%-15% of an organic titanium compound, 10%-40% of a polyethylene compound, 5%-30% of a compatilizer, 10%-50% of functional micro-powder, 5%-10% of an anti-mite agent and 1%-5% of an auxiliary agent.

Owner:江苏瑞康安全装备有限公司

Cable sheath material with high storage stability

ActiveCN103265741AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesDiamineAmmonium polyphosphate

The invention discloses a cable sheath material with high storage stability. The cable sheath material comprises the following raw materials by weight: 98 to 104 parts of chloroprene rubber CR322, 7 to 9 parts of diethylene glycol benzoate, 3 to 4 parts of coumarone, 17 to 20 parts of meerschaum powder, 24 to 30 parts of a modification filling material, 1 to 2 parts of ethene diamine, 3 to 4 parts of phthalate, 3 to 5 parts of ammonium polyphosphate, 1 to 2 parts of N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane, 1 to 2 parts of bis(2,4-dichlorobenzoyl) peroxide, 0.8 to 1 part a promoter TMTD, 2 to 4 parts of talcum powder, 3 to 4 parts of stearic acid and 1 to 2 parts of a promoter M. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

Mobile phone plastic-part material with good heat-dissipation effect

The invention discloses a mobile phone plastic-part material with a good heat-dissipation effect, and belongs to the technical field of mobile phone parts. The mobile phone plastic-part material is prepared from the following components in parts by weight: 10-25 parts of polyformaldehyde plastic, 20-40 parts of ethylene propylene diene monomer rubber, 10-15 parts of white carbon black, 5-15 partsof glycerol monostearate, 1-5 parts of an antibacterial agent, 5-8 parts of glass fibers, 15-30 parts of PVC plastic, , 1-8 parts of zinc stearate, 2-8 parts of polycarbonate, 1-6 parts of paraffin, 5-10 parts of a polyethylene octylene elastomer, 1-4 parts of polyolefin and 1-3 parts of an antioxidant. The mobile phone plastic-part material provided by the invention is high in strength, is not easily cracked, and has good radiation resistance, good waterproof effect, good antibacterial and anti-mildew performance, high aging resistance and excellent flame retardance of products. The productshave high-temperature resistance, good strength and impact strength, low cost, simple operation, and corrosion resistance.

Owner:芜湖辉灿电子科技有限公司

A low temperature resistant cable sheathing material

ActiveCN103342840BGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsPolymer scienceDecabromodiphenyl ether

The invention discloses a low temperature resistant cable sheath material comprises the following raw materials, in parts by weight: 95-102 parts of chloroprene rubber A90, 12-14 parts of polyurethane, 17-20 parts of bauxite, 6-7 parts of an alum powder, 16-24 parts of a modified filler, 3-6 parts of oxidized polyethylene wax, 5-7 parts of poly(1,2-propylene glycol adipate), 1-2 parts of an anti-aging agent MB, 1-2 parts of magnesium oxide, 1-2 parts of anilino-methyl-triethoxysilane, 3-4 parts of extylene diamine tetra (mextylene phosphonic acid) sodium, 1-2 parts of 1,6-hexanediamine, 0.8-1 part of a vulcanizing agent DCBP, and 1-2 parts of decabromodiphenyl ether. The produced cable sheath material is excellent in physical properties, stable in size and low in shrinkage rate, has strong pulling and promoting strength, strong anti-tear strength and strong resilience force performance, and has good properties of oil resistance, heat resistance, flame resistance, sunlight resistance, ozone resistance, acid and alkali resistance, and chemical reagent resistance. The modified filler has good dispersion and low surface tension, and thus the modified filler further improves the tensile strength and the stress at definite elongation of the cable material, reduces heat-generating and compression permanent deformation, not only can delay aging speed of the cable material, but also can resist acid and alkali corrosion and reduce production cost.

Owner:跃进电缆有限公司

Modified filler-containing electric cable sheath material

ActiveCN103351494AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPhosphateMagnesium stearate

The invention discloses a modified filler-containing electric cable sheath material, which comprises the following raw materials, by weight: 97-102 parts of a chloroprene rubber CR121, 2-3 parts of melamine borate, 4-6 parts of magnesium stearate, 2-4 parts of zinc stannate, 1-2 parts of tris(nonylphenyl) phosphate, 2-3 parts of hydrated zinc borate, 1-2 parts of decabromodiphenylethane, 1-2 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 3-4 parts of isocyanate, 2-4 parts of dioctyl phthalate, 6-10 parts of asbestos powder, 10-16 parts of montmorillonite powder, 20-24 parts of a modified filler, 1-2 parts of an anti-aging agent MB, and 0.8-1 part of 2,4-dichlorobenzoyl peroxide. The modified filler-containing electric cable sheath material has characteristics of excellent physical property, stable size, low shrinkage rate, strong tensile strength, strong tearing resistance strength, strong resilience, good oil resistance, good heat resistance, good flame resistance, good sunlight resistance, good ozone resistance, good acid resistance, good alkali resistance, and good chemical reagent resistance.

Owner:ANHUI KANGLIYA CO LTD

Cable protector preparation formula

The invention discloses a cable protector preparation formula which is composed of the following raw materials in parts by weight: 42-52 parts of chlorinated polyethylene, 8-12 parts of epoxidized natural rubber, 1-3 parts of antimonous oxide, 1-4 parts of a sulfonamide vulcanizing accelerator, 15-20 parts of nano calcium carbonate, 3-5 parts of zinc oxide, 1-4 parts of stearic acid, 2-5 parts ofethylene bistearamide, 0.5-1 part of dipentamethylene thiuram hexasulfide, 2-4 parts of a cross-linking agent, 2-5 parts of nano-silica, 0.5-1 part of pentaerythritol, 2-5 parts of carbon black and 3-7 parts of talcum powder. The protector has the characteristics of excellent heat resistance and improved tearing strength and resilience.

Owner:江苏华雄电气有限公司

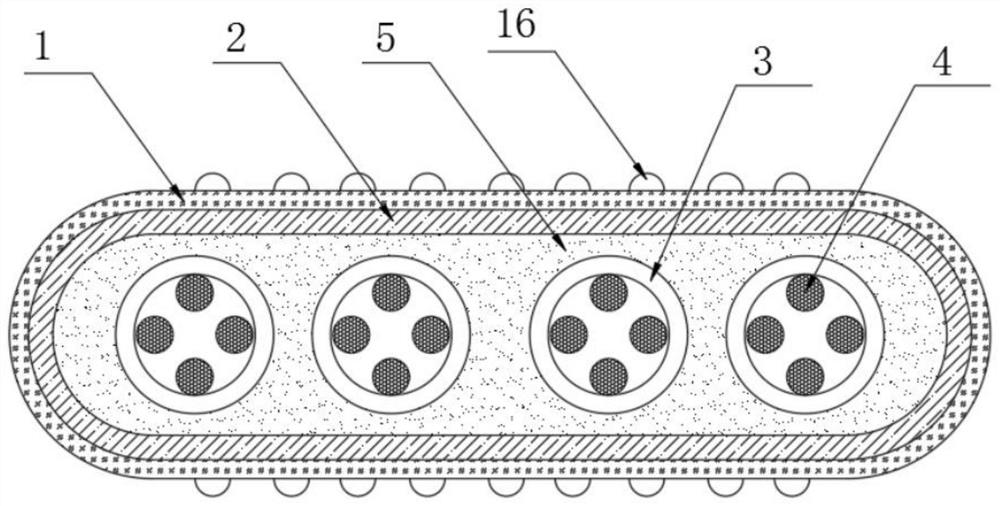

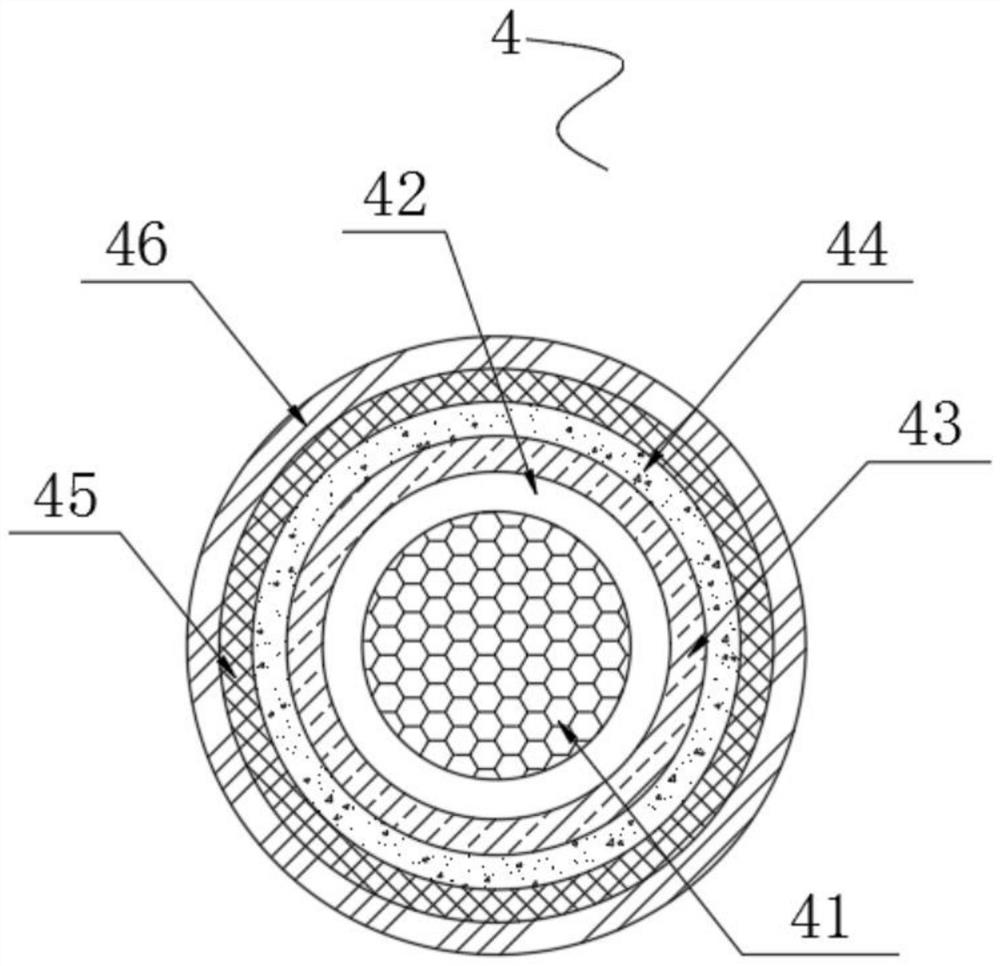

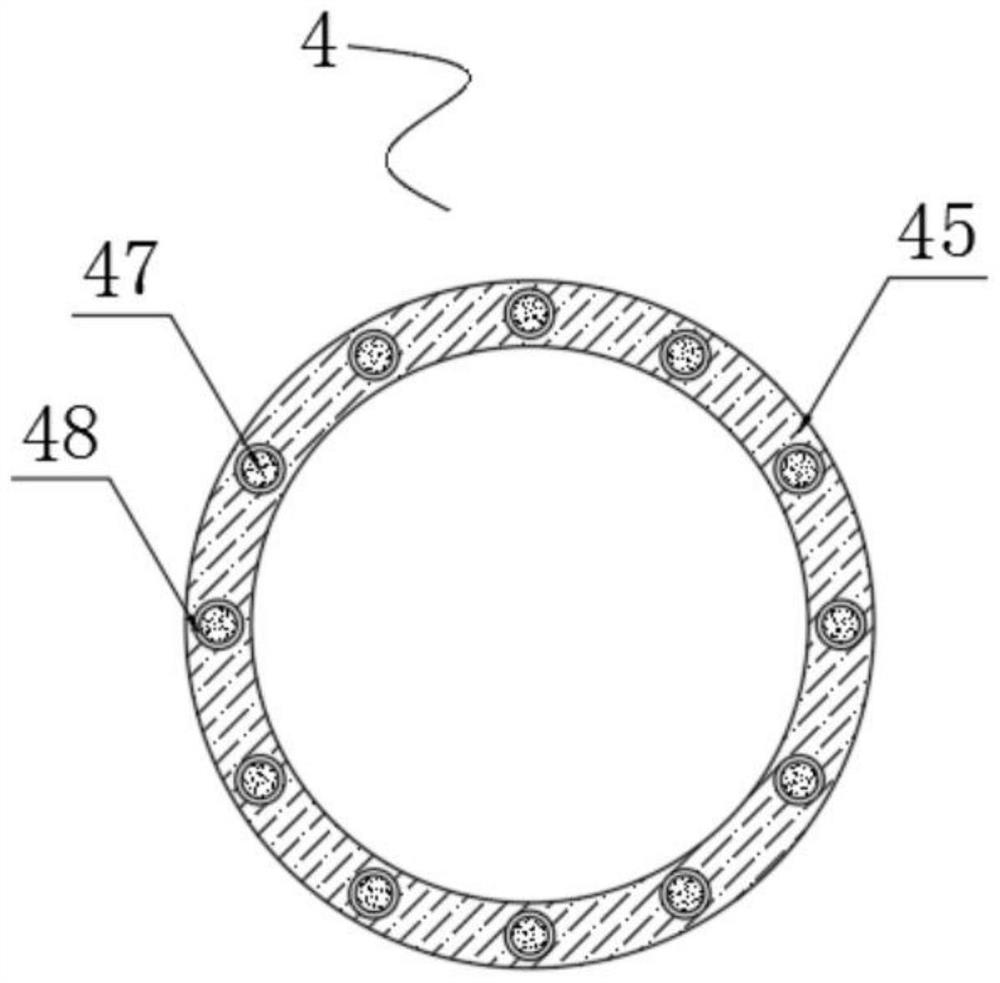

Flat torsion-resistant silicone rubber cable

InactiveCN111755150AHigh tensile strengthEnhance "flexibilityFlat/ribbon cablesInsulated conductorsNeopreneChemical corrosion

The invention discloses a flat torsion-resistant silicone rubber cable, which comprises a protective layer, wherein a flame-retardant layer is adhered to the inner wall of the protective layer throughan adhesive, a sheath is arranged on the inner wall of the flame-retardant layer, cable cores are arranged in the sheath, a gap formed by the flame-retardant layer and the sheath is filled with a filling layer, the number of the cable cores arranged in the sheath is four, the sheath comprises a central pipe arranged in the center of the four cable cores, and a tensile rope is arranged in the central pipe. The invention relates to the technical field of cables. According to the flat torsion-resistant silicone rubber cable, the flame-retardant layer is adhered to the inner wall of the protective layer through the adhesive; the chloroprene rubber block has high tensile strength and excellent oil resistance, heat resistance, flame resistance, sunlight resistance, ozone resistance, acid and alkali resistance, chemical reagent resistance and chemical corrosion resistance, and shielding ropes are arranged in the shielding layer, so that friction generated between a woven mesh layer and the shielding layer when the cable is twisted can be reduced.

Owner:ANHUI DUJIANG CABLE GROUP

A high wear-resistant cable sheathing material

ActiveCN103265738BGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsPolyesterAntimony trioxide

Owner:ANHUI KANGLIYA CO LTD

A flame-retardant cable sheathing material

ActiveCN103265739BGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPolymer scienceCompression set

The invention discloses a flame retardant cable sheath material. The flame retardant cable sheath material comprises the following raw materials by weight: 97 to 100 parts of chloroprene rubber SN23, 10 to 15 parts of chlorinated polyethylene, 15 to 20 parts of hydrotalcite, 8 to 10 parts of magnesium carbonate, 18 to 25 parts of a modification filling material, 4 to 5 parts of trioctyl trimellitate, 3 to 4 parts of methylpentachlorostearate, 1 to 2 parts of an anti-aging agent ODA, 1 to 2 parts of a promoter TMTM, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 3 to 4 parts of ethylene bis stearamide, 2 to 4 parts of aluminum tripolyphosphate, 1 to 2 parts of ferrocene, 1 to 2 parts of an anti-oxidant 168 and 1 to 3 parts of benzotriazole. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

A Corrosion-resistant Cable Sheathing Material

ActiveCN103360650BGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesDispersityCompression set

The invention discloses a corrosion-resistant cable sheath material which is prepared from the following raw materials in parts by weight: 100-102 parts of neoprene CR121, 3-4 parts of aluminum oxide, 4-6 parts of diisobutyl phthalate, 3-4 parts of acetyl triethyl citrate, 1-2 parts of dibasic lead phosphite, 1-2 parts of acetylacetone titanium, 1-2 parts of ethylene glycol dimethacrylate, 2-3 parts of ammonium dihydrogen phosphate, 3-5 parts of ethylene bis stearamide, 25-30 parts of silica powder, 18-24 parts of modified filler, 1-2 parts of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 1-2 parts of anti-aging agent ippd, 3-4 parts of diethanolamine and 0.8-1 part of lead oxide. The modified filler disclosed by the invention has the advantages of favorable dispersity and low surface tension, further enhances the tensile strength and stress at definite elongation of the cable material, lowers the heat generation and permanent compression set, can postpone the aging rate of the cable material, can resist acid / alkali corrosion, and lowers the production cost.

Owner:ANHUI KANGLIYA CO LTD

Rubber material of bearing used in water

The invention discloses a rubber material of a bearing used in water. The rubber material comprises the following raw materials: chloroprene rubber, natural rubber, magnesium oxide, zinc oxide, high-abrasion furnace black, a vulcanizing agent, softening heavy oil, stearic acid, Vaseline, an anti-aging agent D, light calcium carbonate, an accelerant CBS and microcrystalline wax. The rubber material for a rubber bearing is obtained by respectively plastifying the chloroprene rubber and the natural rubber by using an internal mixer, then, mixing the plastified product with the residual raw materials, removing rubber in the mixed material, then, carrying out batching-off, cooling and standing, cutting a rubber sheet, then, placing the rubber sheet into a rubber bearing die, vulcanizing the rubber sheet together with a steel jacket of the rubber bearing in a vulcanizing machine, and deburring the vulcanized rubber bearing. The rubber material has the advantages that the rubber material for the rubber bearing has the characteristics of excellent corrosion resistance such as temperature resistance, heat resistance, sunlight resistance, oxygen resistance, acid and alkali resistance and chemical resistance, the service life of the rubber bearing is prolonged, and a water pump is enabled to be suitable for different liquid media.

Owner:JINZHOU HEAVY WATER PUMP

A kind of cable sheath material containing modified filler

ActiveCN103351494BGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPhosphateMagnesium stearate

The invention discloses a modified filler-containing electric cable sheath material, which comprises the following raw materials, by weight: 97-102 parts of a chloroprene rubber CR121, 2-3 parts of melamine borate, 4-6 parts of magnesium stearate, 2-4 parts of zinc stannate, 1-2 parts of tris(nonylphenyl) phosphate, 2-3 parts of hydrated zinc borate, 1-2 parts of decabromodiphenylethane, 1-2 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole, 3-4 parts of isocyanate, 2-4 parts of dioctyl phthalate, 6-10 parts of asbestos powder, 10-16 parts of montmorillonite powder, 20-24 parts of a modified filler, 1-2 parts of an anti-aging agent MB, and 0.8-1 part of 2,4-dichlorobenzoyl peroxide. The modified filler-containing electric cable sheath material has characteristics of excellent physical property, stable size, low shrinkage rate, strong tensile strength, strong tearing resistance strength, strong resilience, good oil resistance, good heat resistance, good flame resistance, good sunlight resistance, good ozone resistance, good acid resistance, good alkali resistance, and good chemical reagent resistance.

Owner:ANHUI KANGLIYA CO LTD

A kind of high tensile cable sheath material

ActiveCN103242575BGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsEthylene thioureaAccelerant

The invention discloses a high-stretchproof cable sheath material. The material consists of the following raw material in parts by weight: 90-100 parts of chloroprene rubber CR121, 6-8 parts of di(2-ethylhexyl)-4,5-epoxytetrahydrophthalate, 4-6 parts of isophthalic acid ester, 5-7 parts of oxidized polyethylene wax, 2-3 parts of magnesium fluoride, 3-5 parts of ferrocene, 1-2 parts of an anti-aging agent aw, 1-2 parts of 2-benzimidazolethiol, 5-8 parts of dioctyl maleate, 1-2 parts of an accelerator DM, 3-4 parts of zinc borate, 20-30 parts of nano silicon dioxide, 2-3 parts of an antioxidant DSTP, 2-3 parts of ethylene thiourea and 25-35 parts of a modified filler. The produced cable sheath material has excellent physical performance, dimension stability, low shrinkage, strong product stretching accelerant strength, anti-tearing strength and elastic force and good oil resistance, heat resistance, burning resistance, sun light resistance, ozone resistance, acid and alkali resistance and chemical reagent resistance; and the modified filler has good dispersibility and low surface tension, so that the tensile strength and stress at definite elongation of the cable sheath material are further improved, the heat generation and compression permanent deformation are reduced, the aging speed of the cable sheath material can be slowed down, and the cable sheath material can resist acid and alkaline corrosion and is low in production cost.

Owner:ANHUI KANGLIYA CO LTD

A heat-resistant cable sheath material

ActiveCN103265737BGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsPolymer scienceSilanes

The invention discloses a heatproof cable sheath material. The heatproof cable sheath material comprises the following raw materials by weight: 95 to 105 parts of chloroprene rubber S40V, 15 to 20 parts of semi-reinforcing carbon black N774, 20 to 30 parts of a modification filling material, 4 to 7 parts of polyethylene wax, 7 to 10 parts of dibutyl maleate, 4 to 6 parts of itaconate, 2 to 3 parts of magnesium oxide, 2 to 4 parts of ammonium biphosphate, 1 to 2 parts of 4-methylbenzenesulfonyl hydrazide, 1 to 2 parts of anilmomethyl triethoxy silane, 1 to 2 parts of the promoter DM, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of the antioxidant 1010 and 1 to 2 parts of dipentamethylenethiuram hexasulfide. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

An ozone-resistant cable sheath material

ActiveCN103265740BGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesBenzoyl peroxideCis-Butenedioic Acid

The invention discloses an ozone-resistant cable sheath material. The ozone-resistant cable sheath material comprises the following raw materials by weight: 93 to 100 parts of chloroprene rubber M-40, 14 to 19 parts of an SG-4 type PVC resin, 20 to 30 parts of mica powder, 15 to 25 parts of a modification filling material, 4 to 7 parts of glass powder, 4 to 6 parts of dibutyl maleate, 3 to 5 parts of oxidized polyethlene wax, 1 to 2 parts of hydroquinones, 1 to 2 parts of the antioxidant 1010, 2 to 4 parts of borax, 1 to 2 parts of isopropyl tri(dioctylpyrophosphate) titanate, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of benzoyl peroxide, 0.8 to 1 part of sulphur and 0.6 to 1 part of ziram. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

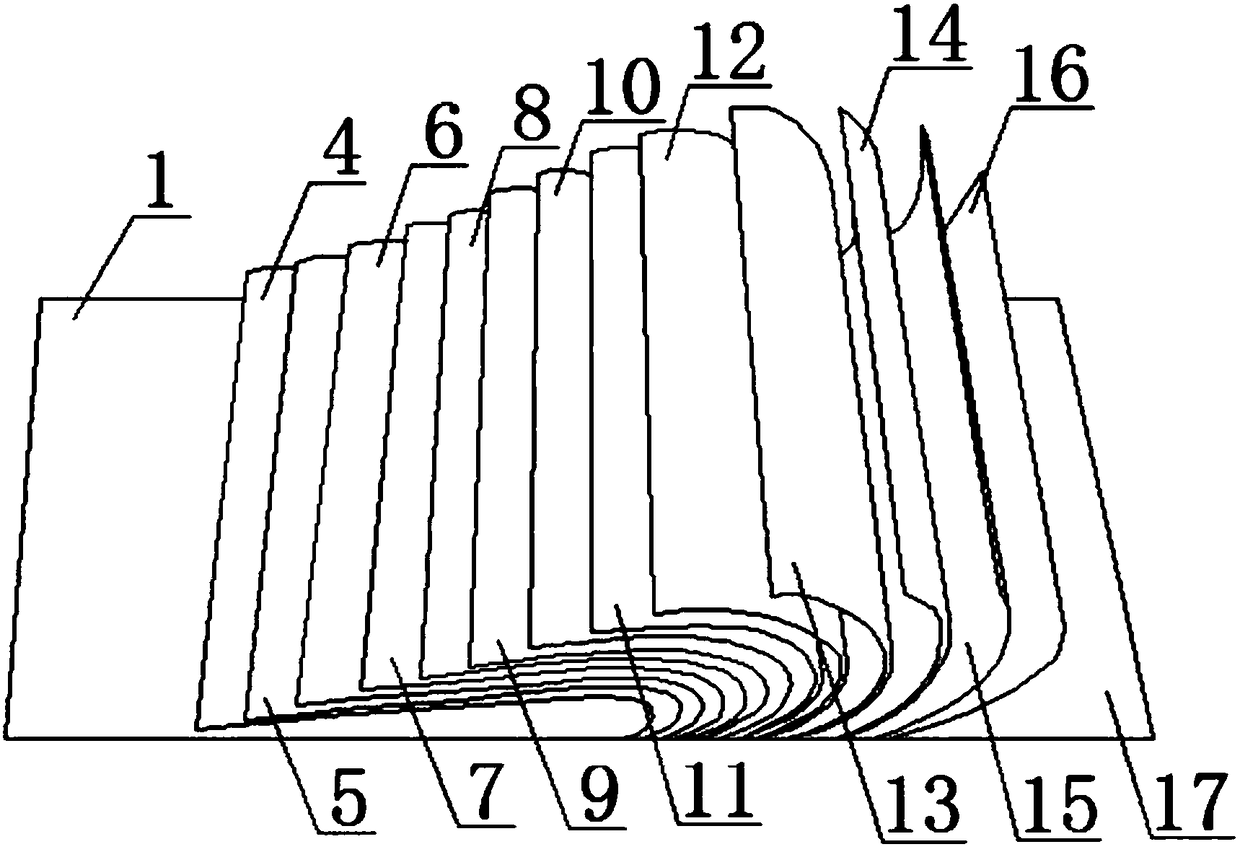

Non-woven fabric for high-stiffness mesh base fabric

PendingCN108582933AStrong stainingImprove dyeing effectSynthetic resin layered productsCellulosic plastic layered productsPolyesterHigh stiffness

The invention discloses a non-woven fabric for a high-stiffness mesh base fabric. The non-woven fabric comprises a non-woven fabric body. A first viscose layer is arranged at the upper surface of thenon-woven fabric body, an adhesive sticker layer is arranged below the first viscose layer, a first chinlon layer is arranged below the adhesive sticker layer, a first polyester layer is arranged below the first chinlon layer, a first acrylic fiber layer is arranged below the first polyester layer, a first vinylon layer is arranged below the first acrylic fiber layer, a first spandex layer is arranged below the first vinylon layer, and a fiber net is arranged below the first spandex layer. The non-woven fabric has the various advantages of being good in hygroscopicity, dyeing property, impactresistance, heat resistance and corrosion resistance, easy to clean, capable of being dried rapidly, durable, solid, good in chemical stability, sunlight resistance, using comfort and elasticity and the like.

Owner:浙江明盛达医用材料科技股份有限公司

Special material for corrosion resistant communication cable protective sleeve and preparation method thereof

InactiveCN104312146AImprove corrosion resistanceImprove water resistancePlastic/resin/waxes insulatorsAntimony trioxideButyl phthalyl butyl glycolate

The invention discloses a special material for a corrosion resistant communication cable protective sleeve and a preparation method thereof. The special material is made from the following raw materials in parts by weight: 46-62 parts of nylon 66, 28-36 parts of tetrafluoroethylene alkoxy resin, 16-24 parts of chlorinated polyether resin, 3-5 parts of docosanoic acid zinc, 11-16 parts of phosphonitrilic chloride trimer, 10-15 parts of hollow glass beads, 15-20 parts of strong magnesium powder, 2-4 parts of wool acid lithium, 3-5 parts of O-diallyl bisphenol A, 14-18 parts of antimonous oxide, 16-22 parts of butyl phthalyl butyl glycolate, 3-5 parts of stearyldiethanolamine, 1-2 parts of sorbitan monolaurate, 2-4 parts of stearoylbenzoylmethane, 3-6 parts of oleamide, 2-3 parts of vinylferrocene, 10-15 parts of expandable graphite powder, 1-2 parts of 4, 4 '-bis (alpha. alpha dimethylbenzyl) diphenylamine and 12-17 parts of flame retardant. The material of the protective sleeve provided by the invention has excellent corrosion resistance, long service life and wide application range.

Owner:安徽电信器材贸易工业有限责任公司

A cable sheath material with high storage stability

ActiveCN103265741BGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesEngineeringStearic acid

Owner:ANHUI KANGLIYA CO LTD

Method for increasing anti-sun light radiation of biological pesticide

InactiveCN1275526CWon't leaveImprove sunlight resistanceBiocideAnimal repellantsBacillus thuringiensisLength wave

Owner:UNIV OF SCI & TECH BEIJING

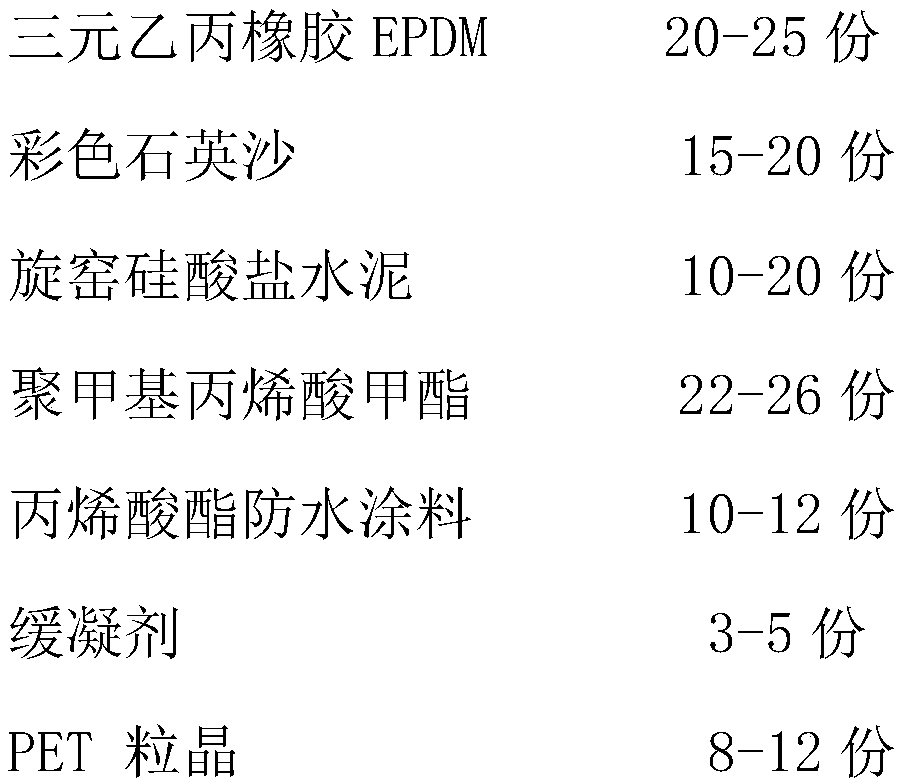

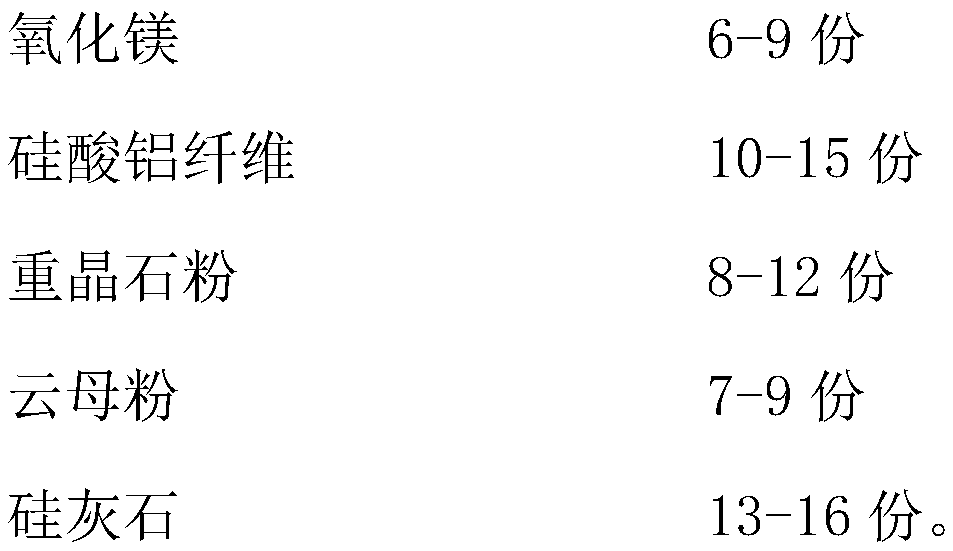

Water-based EPDM color pavement material

The invention discloses a water-based EPDM color pavement material. The water-based EPDM color pavement material consists of the following components in parts by weight: 22 parts of EPDM, 18 parts ofcolored quartz sand, 15 parts of rotary kiln silicate cement, 24 parts of polymethyl methacrylate, 11 parts of acrylate waterproof coating, 4 parts of a retarder, 10 parts of PET granular crystal, 8 parts of magnesium oxide, 13 parts of aluminum silicate fiber and the like. The water-based EPDM color pavement material has excellent aging resistance, weather resistance, ozone resistance, sunlight resistance, heat resistance, water resistance, water vapor resistance, ultraviolet resistance, radiation resistance and other properties, and EPDM can play a role of a polymer type antioxidant or anti-aging agent.

Owner:SHANGHAI SENRUI ROAD ENG TECH

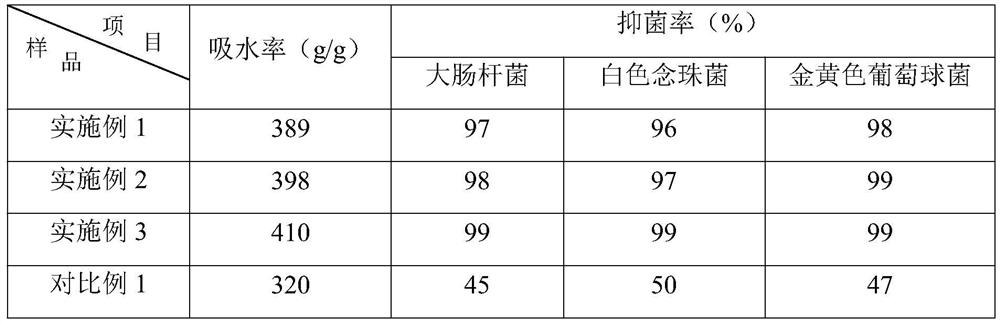

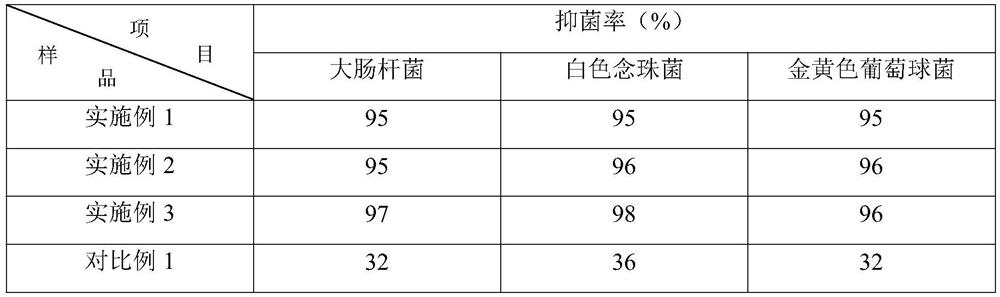

A moisture-absorbing and antibacterial insole

ActiveCN110141019BSoft and comfortable to wearHas the function of health care and skin careInsolesFiberPolymer science

The invention discloses a moisture-absorbing antibacterial insole, which comprises a surface layer, a moisture-absorbing antibacterial layer and a bottom layer, wherein the surface layer is a fiber mesh layer, and the bottom layer is a polyurethane layer; the moisture-absorbing antibacterial layer is a quantum Dot composite film, the quantum dot composite film uses polymer material as matrix material, quantum dots as filler, and is prepared by 3D printing technology; It can fundamentally solve the effect of foot sweat and foot odor, and at the same time, the insole has the health care function of promoting the blood circulation of the feet.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com