Special material for corrosion resistant communication cable protective sleeve and preparation method thereof

A communication optical cable and sheathing technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor corrosion resistance, affecting optical fiber transmission, etc., and achieve the effect of long service life, wide application range and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

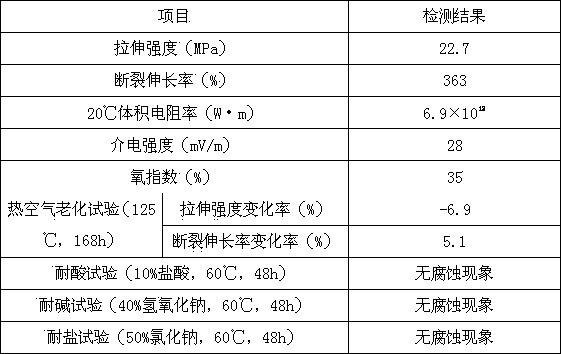

[0012] A special material for corrosion-resistant communication optical cable sheath tube, made of the following raw materials in weight (kg): nylon 66 54, tetrafluoroethylene alkoxy resin 32, chloroether resin 18, zinc behenate 4, hexachlorocycline Triphosphazene 14, hollow glass microspheres 12, magnesium strong powder 18, lithium lanolate 3, o-diallyl bisphenol A 4, antimony trioxide 16, butyl phthalyl glycolate butyl ester 18, hard Fatty acid diethanolamine 4, sorbitan monolaurate 1.5, stearyl benzoyl methane 3, oleic acid amide 4.5, vinyl ferrocene 2.5, expandable graphite powder 12, 4.4'-bis(α. α-Dimethylbenzyl) diphenylamine 1.5, flame retardant 15;

[0013] The preparation method of the auxiliary agent is as follows: a. Take the following raw materials by weight (kg): calcium zirconate 12, methylene bis(2,4-di-tert-butylphenoxy)aluminum phosphate 4, titanium oxalate 3.5, Tourite 10, 3,5-di-tert-butyl-4-hydroxybenzoic acid methyl ester 2.5, dodecyl glucoside 1.5, N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com