Water-based EPDM color pavement material

A pavement material and color technology, which is applied in the field of water-based EPDM colored pavement materials, can solve the problems of aging resistance, ultraviolet radiation resistance, acid resistance, poor performance, and affecting the ground, etc., to achieve a wide range of applicable temperatures and reduce the cost of rubber materials , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

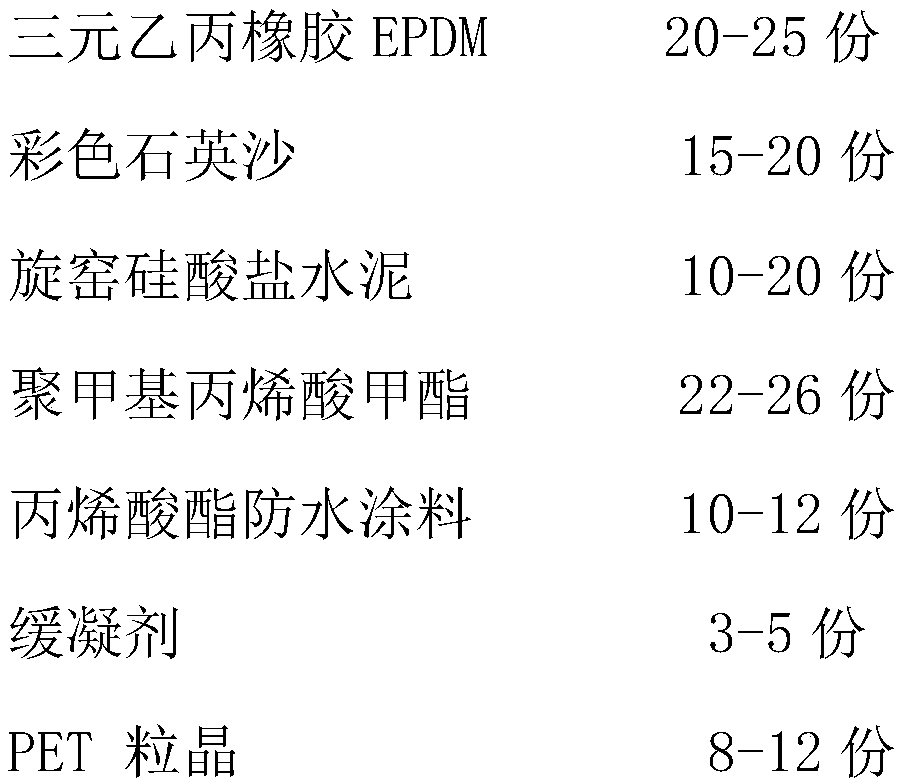

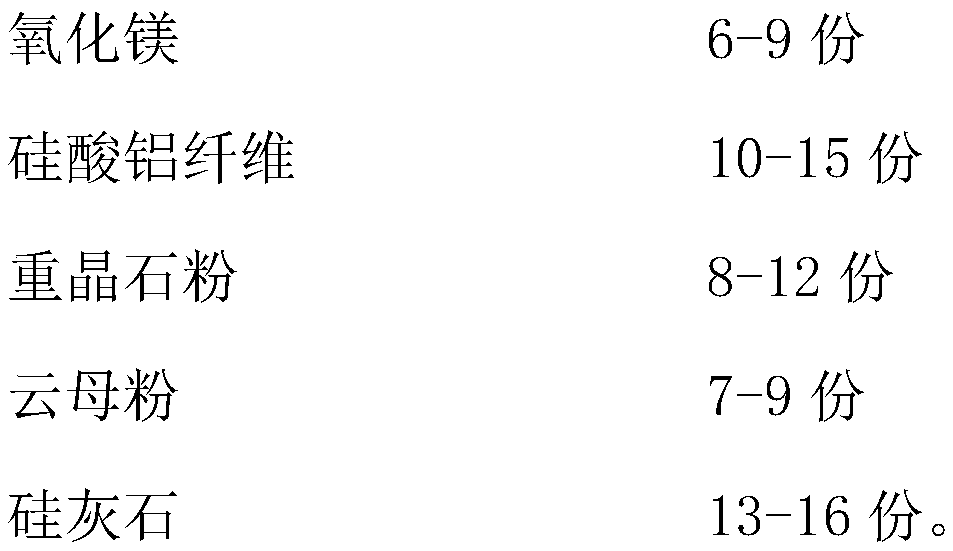

[0026] A water-based EPDM colored pavement material consists of the following parts by weight:

[0027] 20 parts of EPDM, 15 parts of colored quartz sand, 10 parts of rotary kiln portland cement, 22 parts of polymethyl methacrylate, 10 parts of acrylate waterproof coating, 3 parts of retarder, 8 parts of PET grain 6 parts, magnesium oxide 6 parts, aluminum silicate fiber 10 parts, barite powder 8 parts, mica powder 7 parts, wollastonite 13 parts.

[0028] A kind of preparation method of water-based EPDM color pavement material, comprises the following steps:

[0029] Step 1: First pass the colored quartz sand and wollastonite through the grinder to crush the large solid particles, and then pass through an 80-mesh screen to obtain coarse aggregate for later use; wollastonite is composed of CaO48.25% and SiO251.75% .

[0030] Step 2: Add a retarder to the coarse aggregate obtained in Step 1. The retarder is selected from lignin sulfonate and organic phosphonic acid (salt) and ...

Embodiment 2

[0036] A water-based EPDM colored pavement material consists of the following parts by weight:

[0037] 22 parts of EPDM, 18 parts of colored quartz sand, 15 parts of rotary kiln Portland cement, 24 parts of polymethyl methacrylate, 11 parts of acrylate waterproof coating, and 4 parts of retarder 10 parts, 10 parts of PET grain, 8 parts of magnesium oxide, 13 parts of aluminum silicate fiber, 10 parts of barite powder, 8 parts of mica powder, and 15 parts of wollastonite.

[0038] A kind of preparation method of water-based EPDM color pavement material, comprises the following steps:

[0039] Step 1: First pass the colored quartz sand and wollastonite through the grinder to crush the large solid particles, and then pass through an 80-mesh screen to obtain coarse aggregate for later use; wollastonite is composed of CaO48.25% and SiO251.75% .

[0040] Step 2: Add retarder to the coarse aggregate obtained in step 1, and use rotary kiln Portland cement as a stabilizing material ...

Embodiment 3

[0045] A water-based EPDM colored pavement material consists of the following parts by weight:

[0046] 25 parts of EPDM, 20 parts of colored quartz sand, 20 parts of rotary kiln Portland cement, 26 parts of polymethyl methacrylate, 12 parts of acrylate waterproof coating, 5 parts of retarder, 12 parts of PET grain , 9 parts of magnesium oxide, 15 parts of aluminum silicate fiber, 12 parts of barite powder, 9 parts of mica powder, and 16 parts of wollastonite.

[0047] Preferably, 22 parts of EPDM, 18 parts of colored quartz sand, 15 parts of rotary kiln portland cement, 24 parts of polymethyl methacrylate, 11 parts of acrylate waterproof coating, and 11 parts of retarded 4 parts are used as agent, 10 parts are used as PET grain, 8 parts are used as magnesium oxide, 13 parts are used as aluminum silicate fiber, 10 parts are used as barite powder, 8 parts are used as mica powder, and 15 parts are used as wollastonite.

[0048] A kind of preparation method of water-based EPDM c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com