High pressure rotary jet grouting pile process combining PVC pipe and rotary jet grouting drill bit thereof

A technology of high-pressure rotary grouting piles and PVC pipes, which is applied in the direction of foundation structure engineering, sheet pile walls, earthwork drilling and mining, etc. It can solve problems such as water accumulation in foundation pits, inconvenient construction, and large geological particles, so as to improve construction efficiency and improve Work efficiency, water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

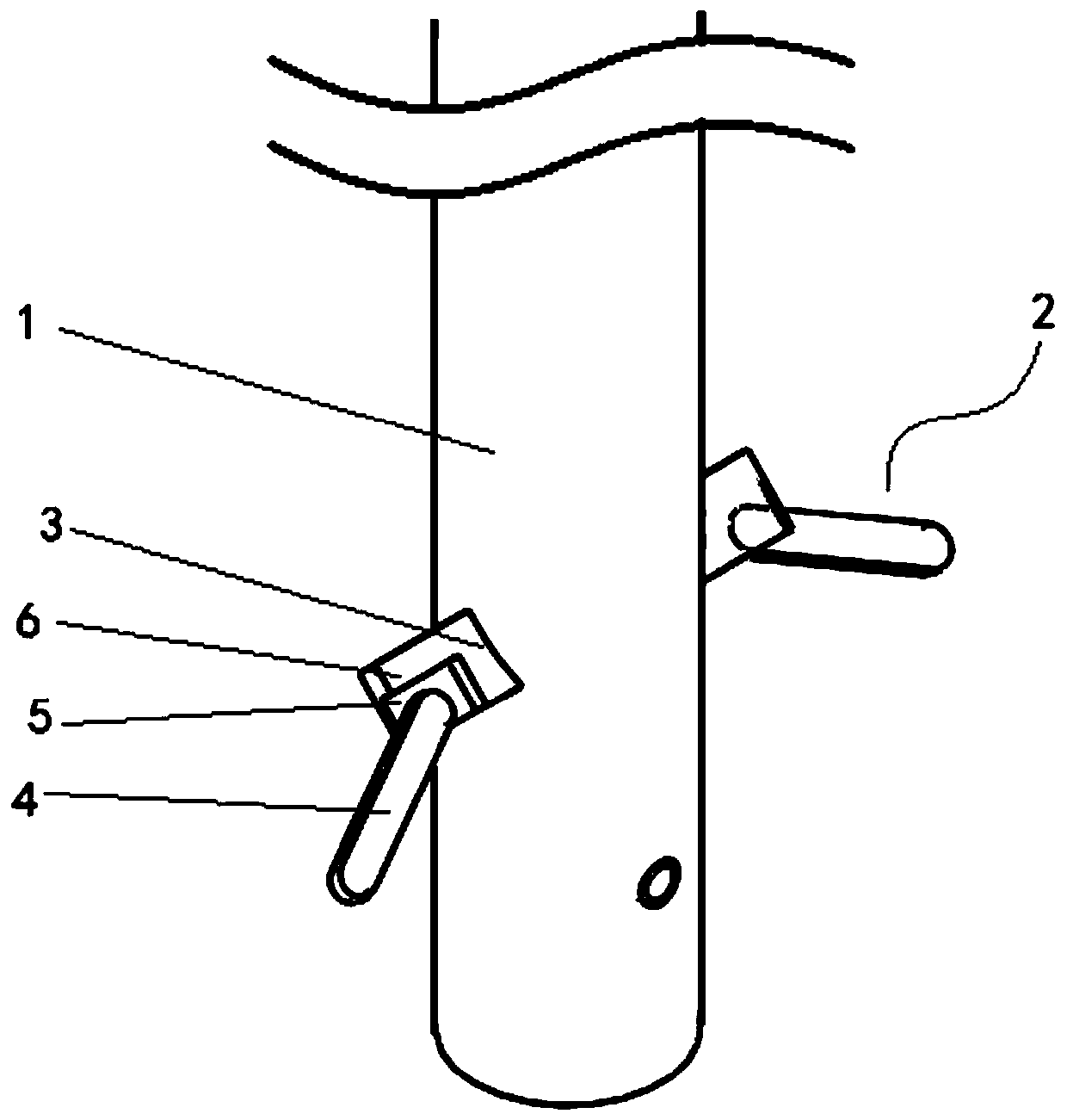

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

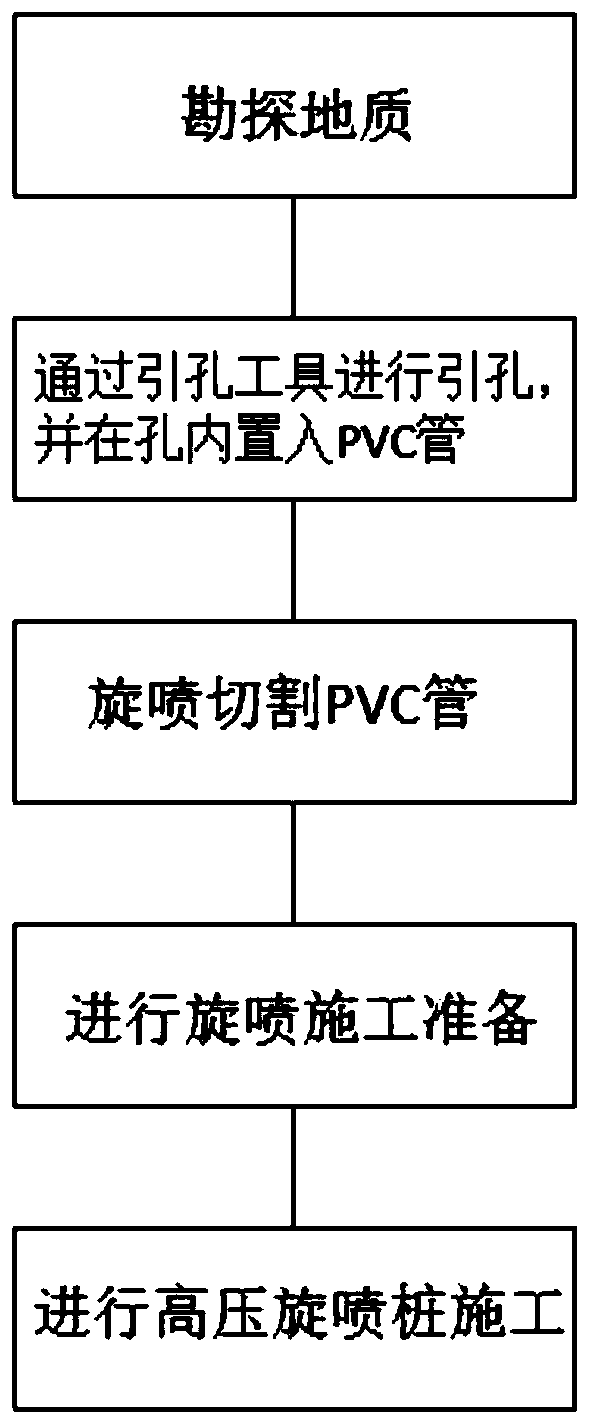

[0035] A kind of high-pressure rotary spraying pile technology combined with PVC pipe, comprising the following steps,

[0036] (1) Exploration geology. During geological exploration, the particle size of the round gravel layer is judged according to the local excavation situation on site. If there are larger stones in the round gravel layer, it is necessary to carry out the high-pressure jet jetting pile process by this method; If the particles of the pebble layer are small, high-pressure jet jetting can be directly carried out through the jet jet drill.

[0037] In this embodiment, the results of geological exploration are,

[0038] 1st layer, plain fill (mlQ4): yellow-gray, gray-yellow, loose, its composition is mainly cohesive soil and coarse sand, with a small amount of gravel in some parts, the particle size of the gravel is generally between 3 and 50mm, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com