Online thickness monitoring device and method for accumulated dust in bottom of horizontal flue

A technology of horizontal flue and ash thickness, which is applied to measurement devices, instruments, etc., can solve the problems of limited resolution of ultrasonic ranging methods, difficulty in eliminating environmental interference factors, and inability to adapt to online monitoring, so as to avoid random errors in temperature measurement. , Low manufacturing cost, stable and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

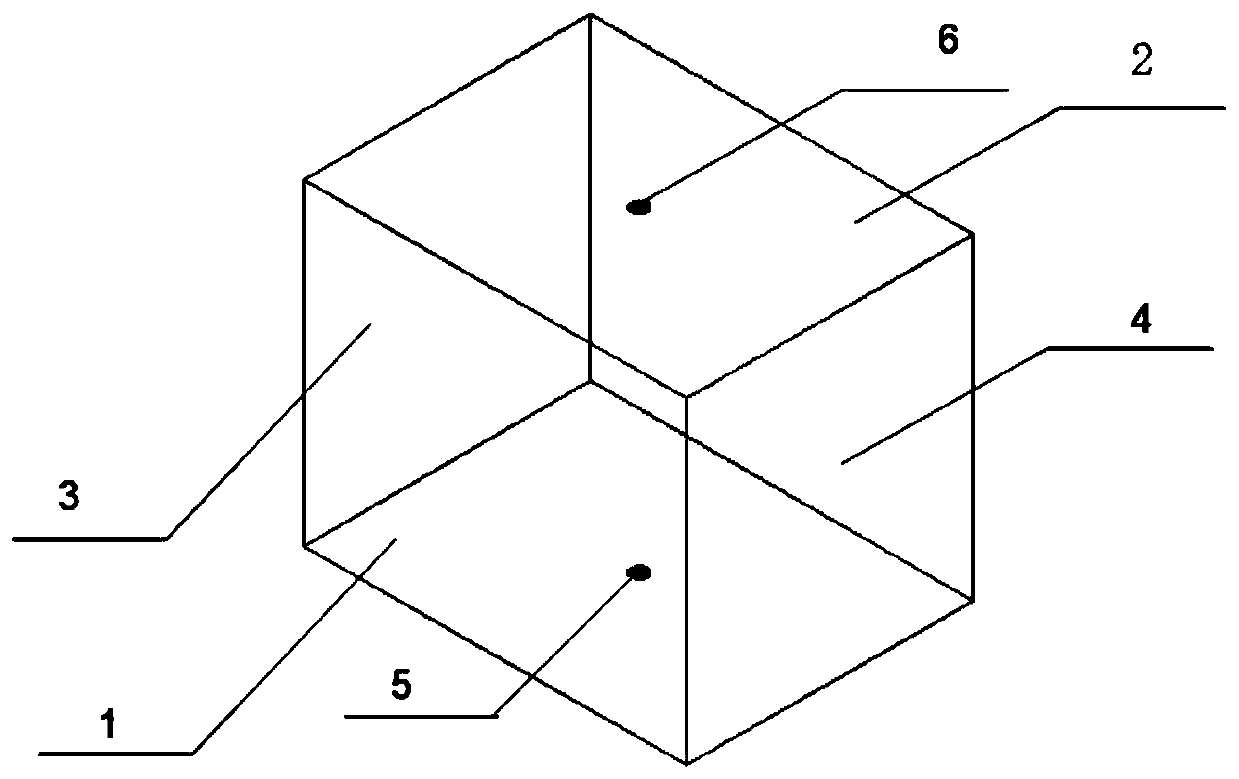

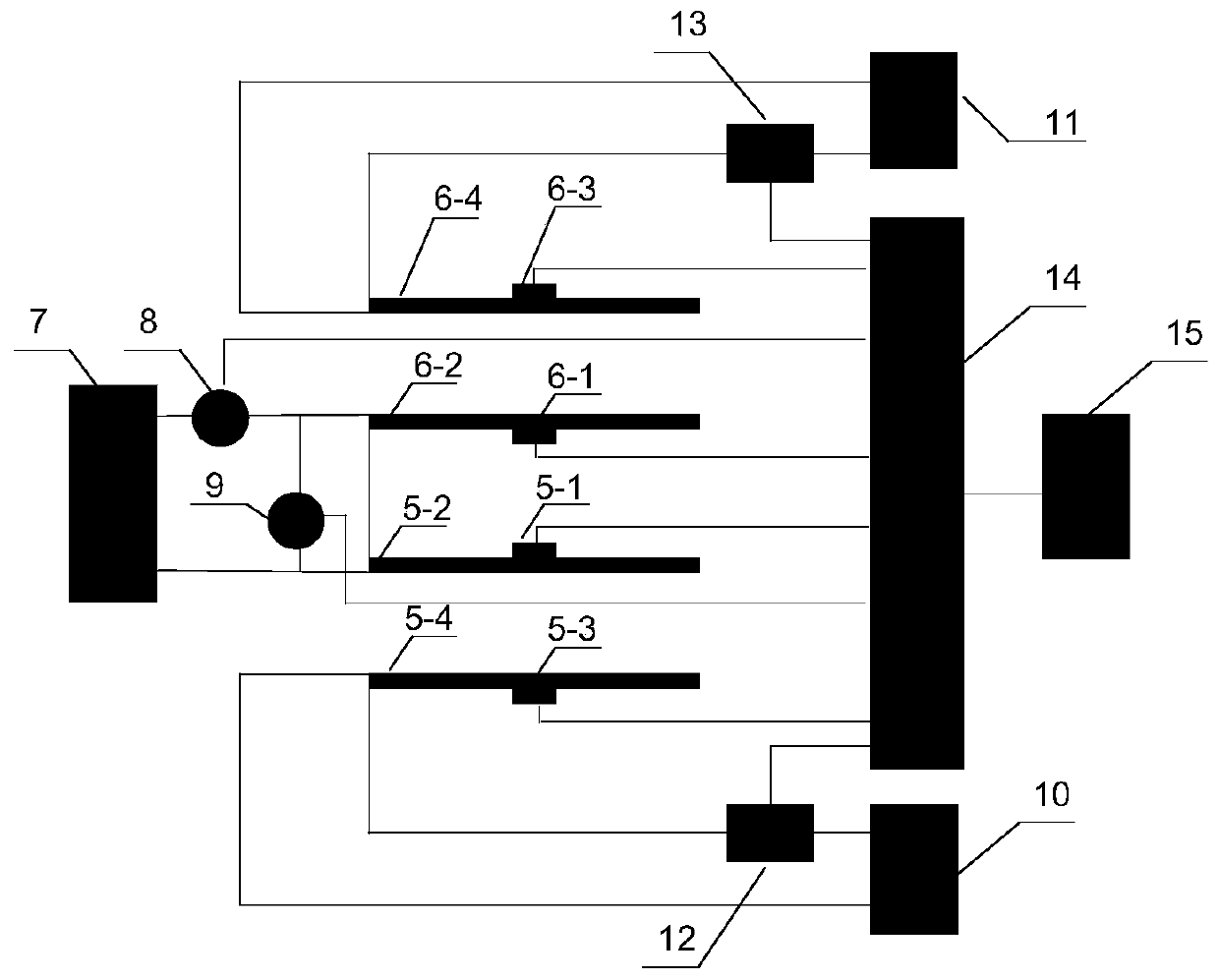

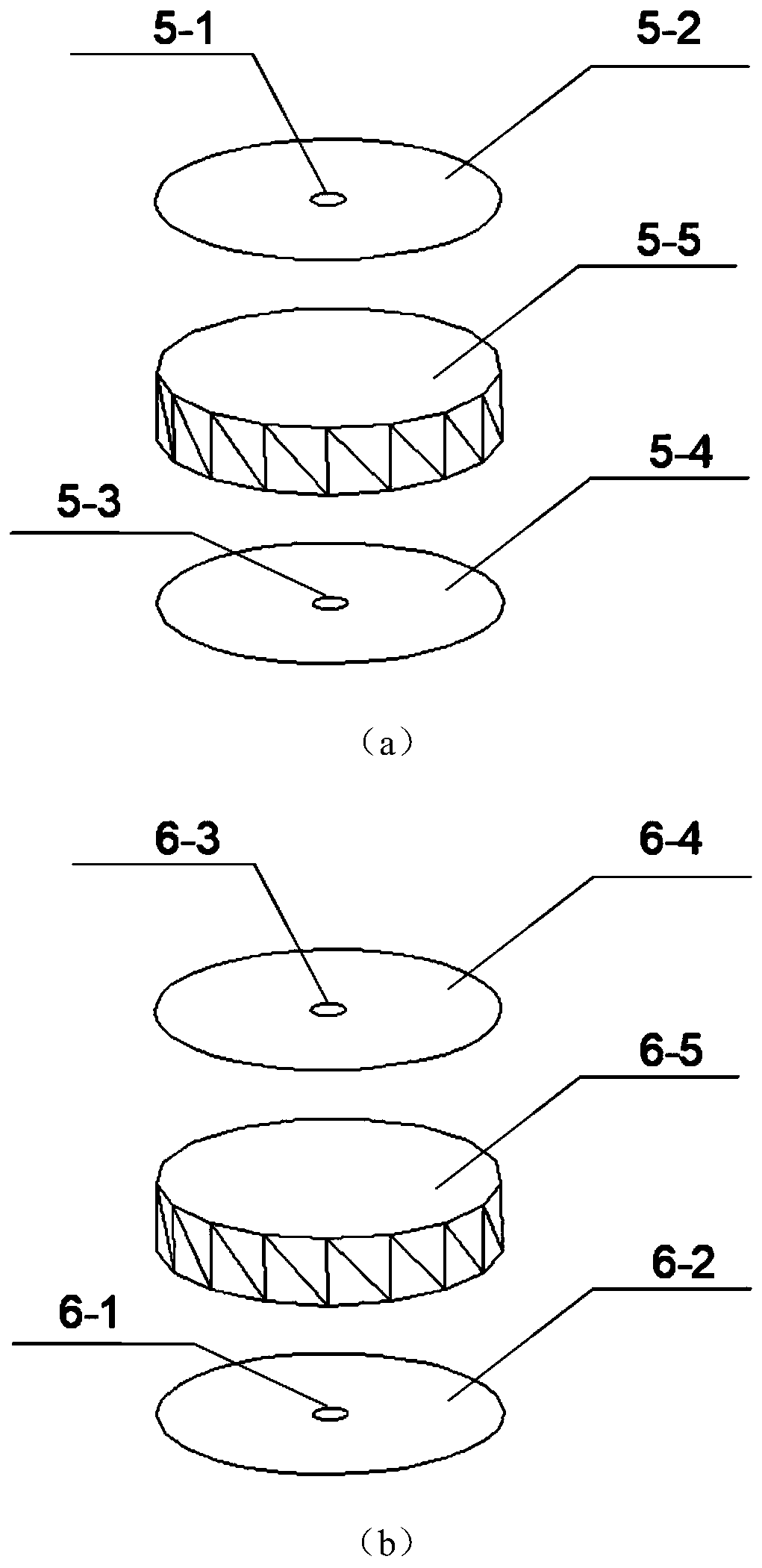

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Install a constant power electric heating measuring piece with a surface temperature sensor at the centroid of the bottom surface of the straight horizontal flue flush with the bottom surface, and install a heating power measuring piece with the same size as the bottom measuring piece at the centroid of the upper wall surface corresponding to the bottom surface The same reference plate, also with a surface temperature sensor. Since the power of the two heaters is the same and the heat dissipation conditions are the same, the temperature of the measuring piece and the reference piece should be consistent and change synchronously with the airflow conditions in the flue and the external heat dissipation conditions when there is no dust accumulation at the bottom. When dust accumulates at the bottom of the channel, the heat dissipation conditions on the measuring pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com