Sensor in field of process automation and its manufacture

A process automation and sensor technology, applied in the field of sensors, can solve problems such as corrosion and achieve the effect of preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

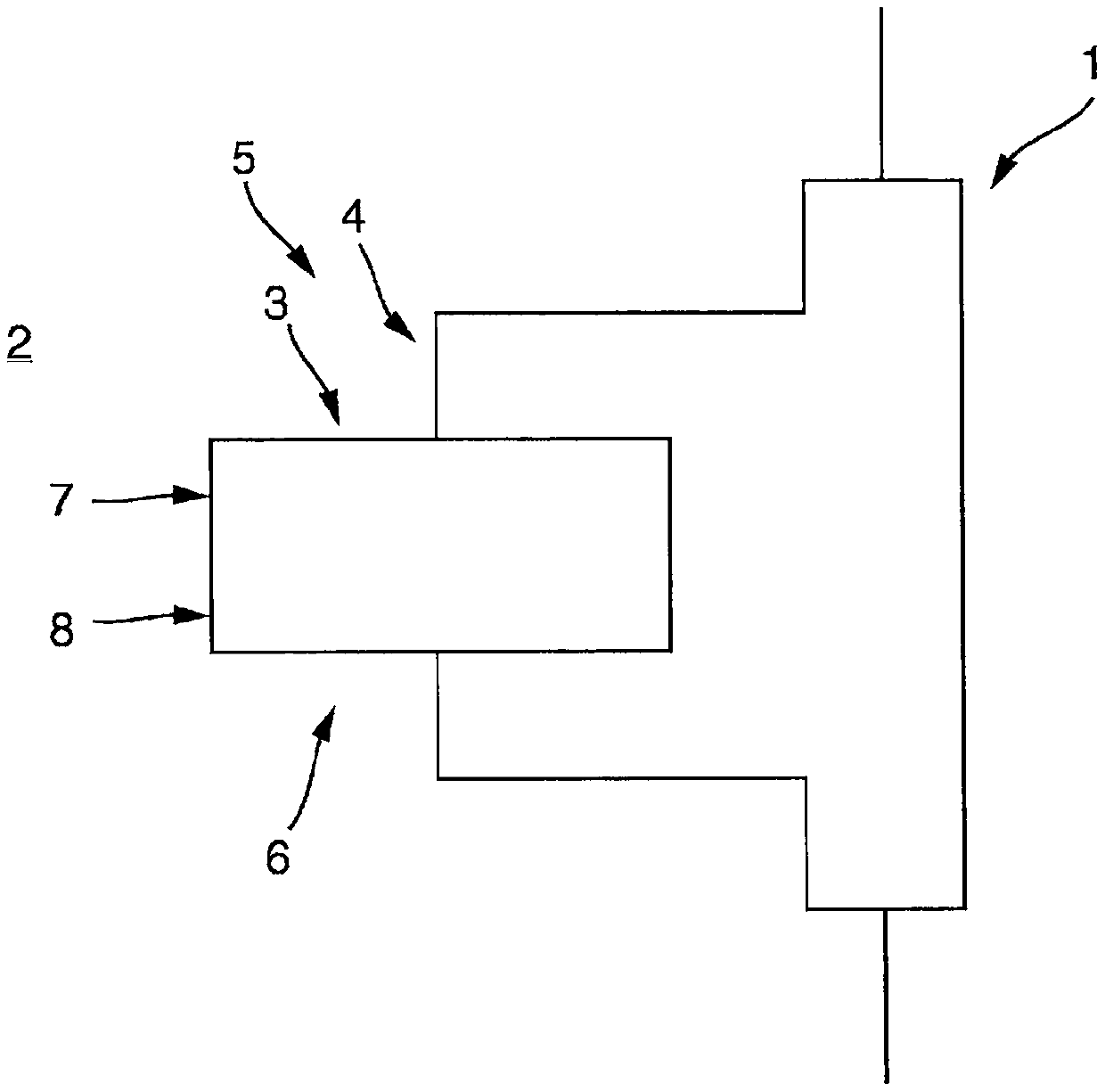

[0033] The sensor 1 comprises at least one measured sensor element for the automation of the detection process. The sensor 1 is then for example a pH sensor, also known as an ISFET - usually an ion-selective sensor, which is a sensor for measuring redox potential, measuring e.g. wavelengths in the UV, IR and / or visible range Absorption of electromagnetic waves in the medium, measurement of oxygen, measurement of conductivity, measurement of turbidity, measurement of the concentration of non-metallic materials or measurement of temperature, and measurement of their corresponding measurands.

[0034] figure 1 Such a sensor is shown, which comprises at least one metallic segment 8 .

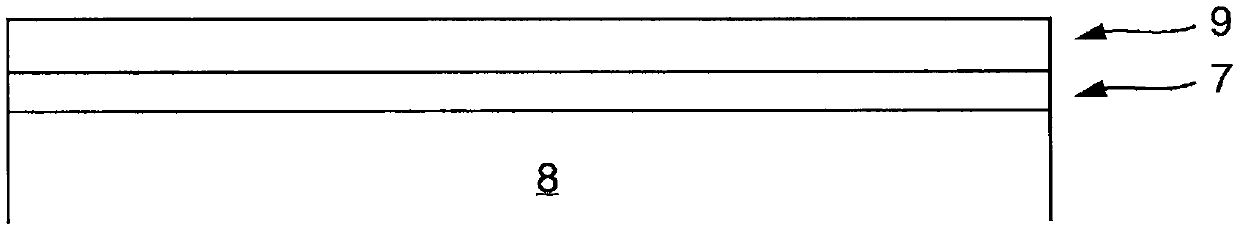

[0035] The sensor 1 is at least partially immersed in the medium 2 to be measured. This leads to the media contact section 6 . The metal section 8 can also at least partially form the dielectric contact section 6 . The medium-contact section 6 of the sensor 1 comprises at least two distinct regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com