Coated calcium carbonate for pitch and/or stickies control

A technology of calcium carbonate and adhesive, applied in pulp fat/resin/pitch/wax removal, coating, paper coating, etc., can solve problems such as paper web breakage, paper staining, machine stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

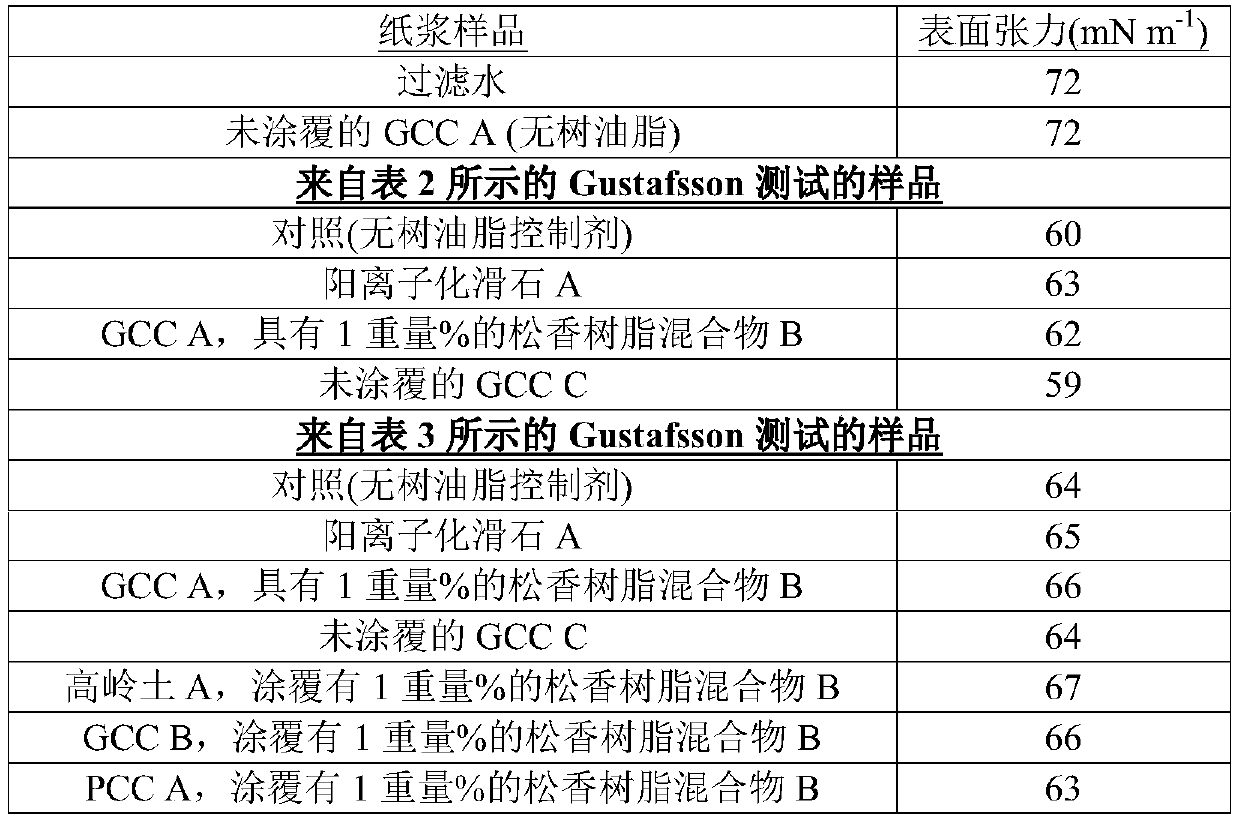

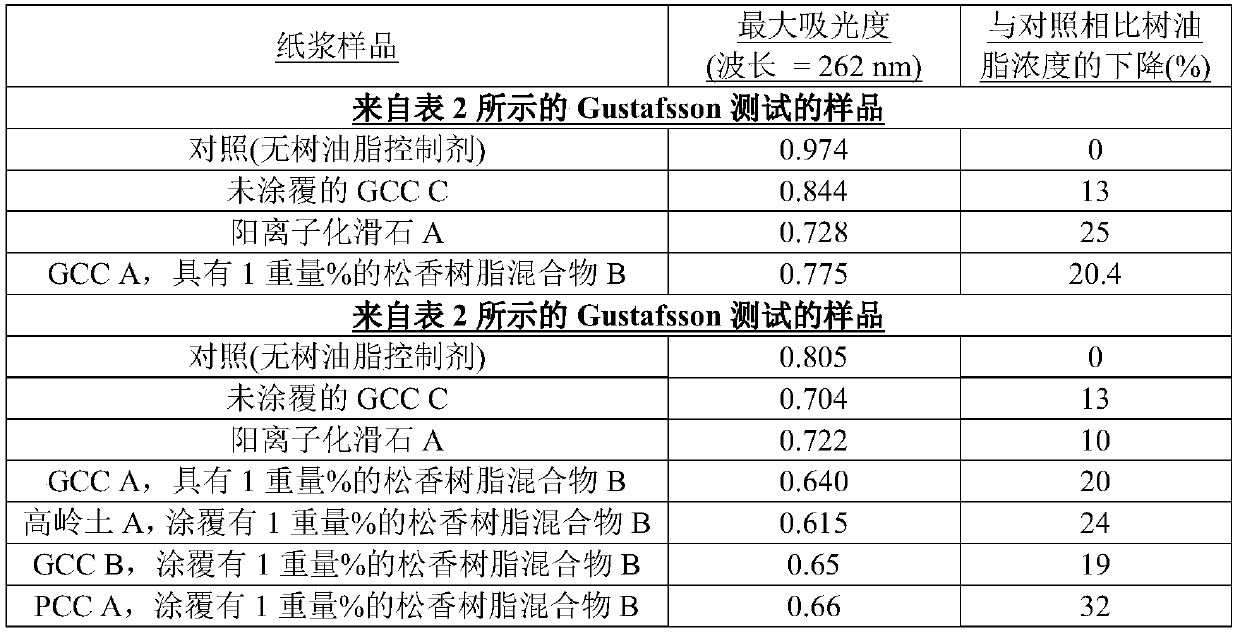

[0083] Gustafsson test

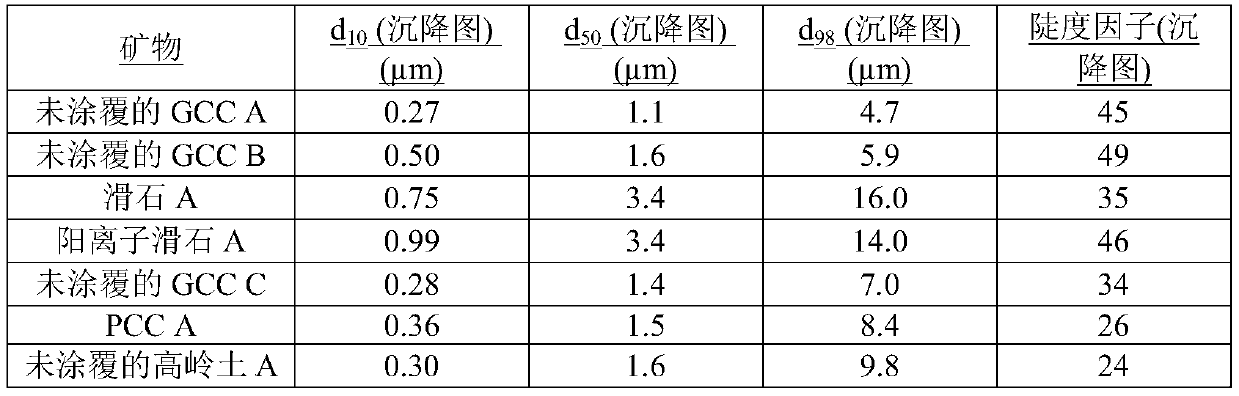

[0084] The Gustafsson test described above was used to test the resinous oil control capabilities of the minerals described in Table 1.

[0085] The artificial resin oil used was dissolved in acetone (500cm 3 ) in rosin resin mixture A (rosin resin with a ring and ball softening point of 80°C and an acid value of 150mgKOH / g), rosin resin mixture B (a rosin with a ring and ball softening point of 65°C and an acid value of 150mgKOH / g resin) or rosin resin mixture C (rosin resin with a viscosity of 1000mPa.s and an acid value of 150mgKOH / g at 70°C) (by Lawter TM Provide) (30g), obtain artificial resin oil solution (0.06g cm -3 ). Protect from sunlight during storage.

[0086] The pulp was Botnia pulp (440 g) soaked overnight in filtered water (10 L). This was added to a Weverk type beater along with filtered water (12L). Run the beater for 15 minutes, then add a weight (5.568kg) to engage the bed, and run the beater for 55 minutes to get a Canadian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com