Intelligent equipment inspection method for large hydropower station

A technology of intelligent inspection and hydropower station, applied in the field of inspection, can solve problems such as complex structure and irregular equipment layout, and achieve the effects of improving timeliness, reducing personnel work intensity, and avoiding missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

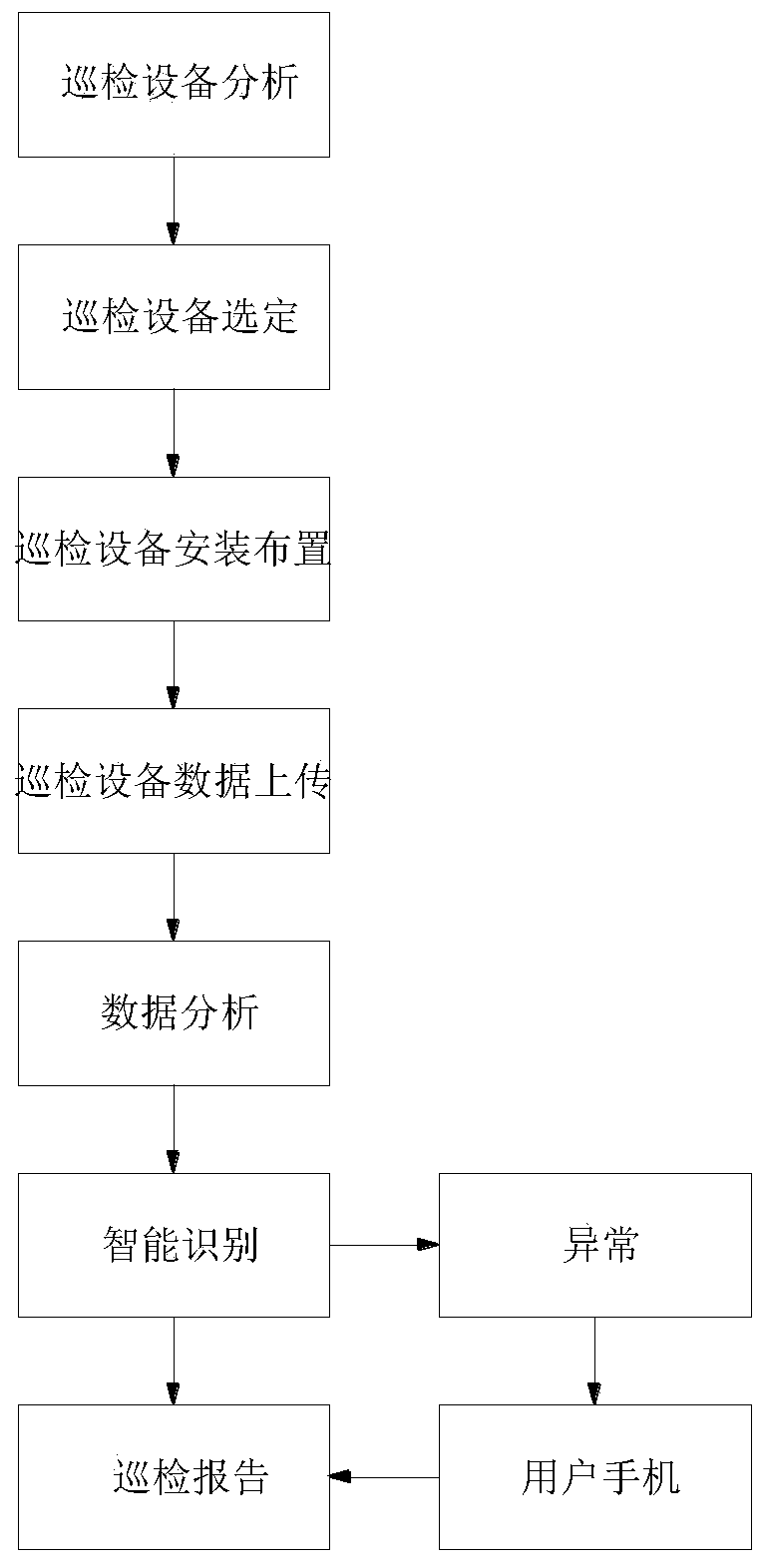

[0038] Embodiment 1: see figure 1 , an intelligent inspection method for equipment in a large hydropower station, the method steps are as follows,

[0039] Step 1. According to the characteristics of large-scale hydropower station equipment, analyze the inspection equipment and determine the inspection content. According to the characteristics of large-scale hydropower station equipment, analyze the inspection equipment, including the focus of attention, normal state, abnormal state characteristics, and prone to occurrence of equipment. Defect location and defect type. For example, the joints of water supply pipes in hydropower stations are prone to water leakage and water spray defects due to loose connection bolts or aging seals at the joints; for example, during the operation of electrical equipment in hydropower stations, equipment damage due to aging or unstable voltage of components;

[0040] Step 2. According to the location of the inspection equipment and the content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com