Printed food freshness intelligent label, production method and application

A technology of smart labels and production methods, applied in the fields of application, chemical method analysis, sealing, etc., can solve the problems of cumbersome detection steps, expensive instruments, long time consumption, etc., to avoid complicated production steps, easy to use methods, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

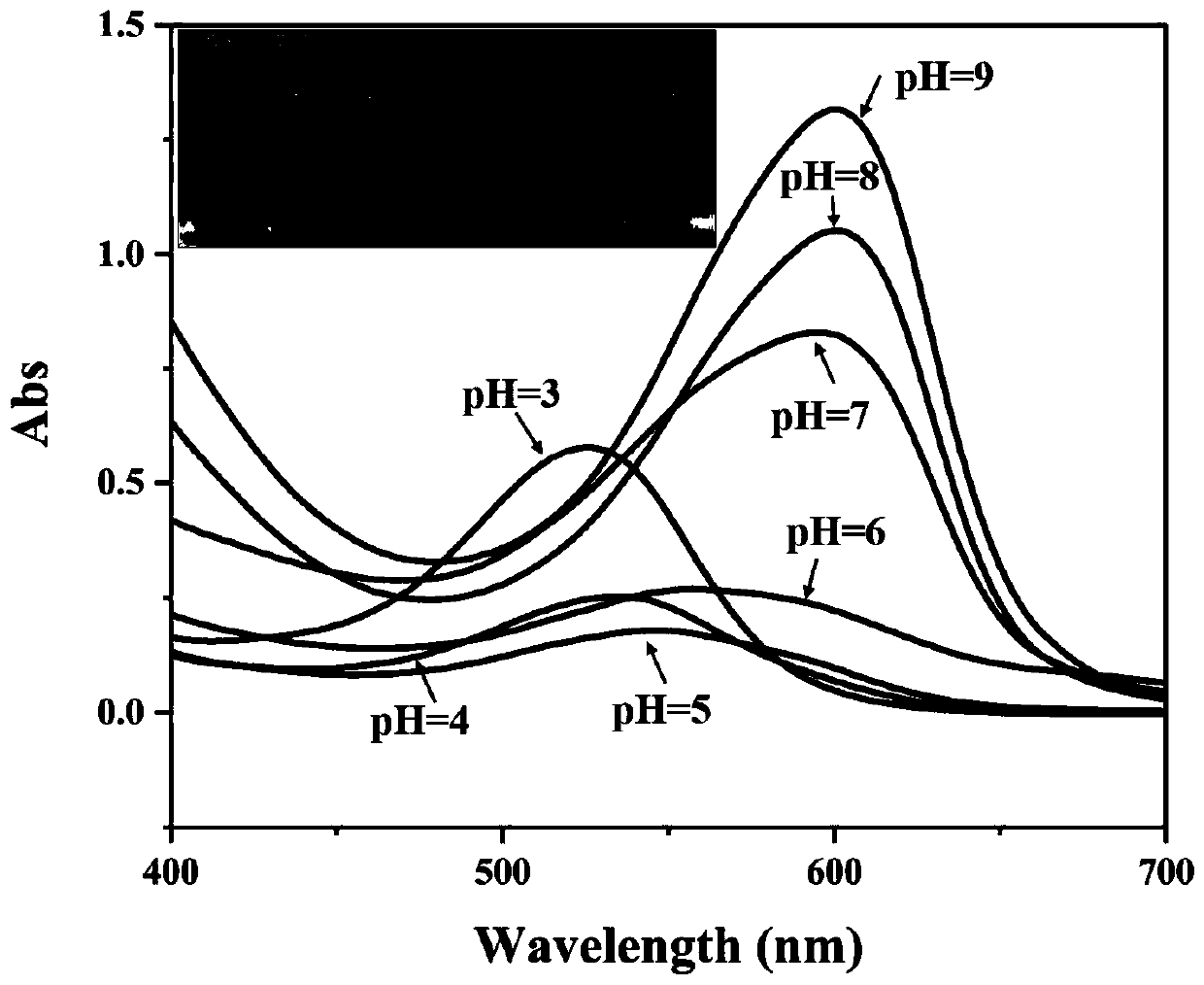

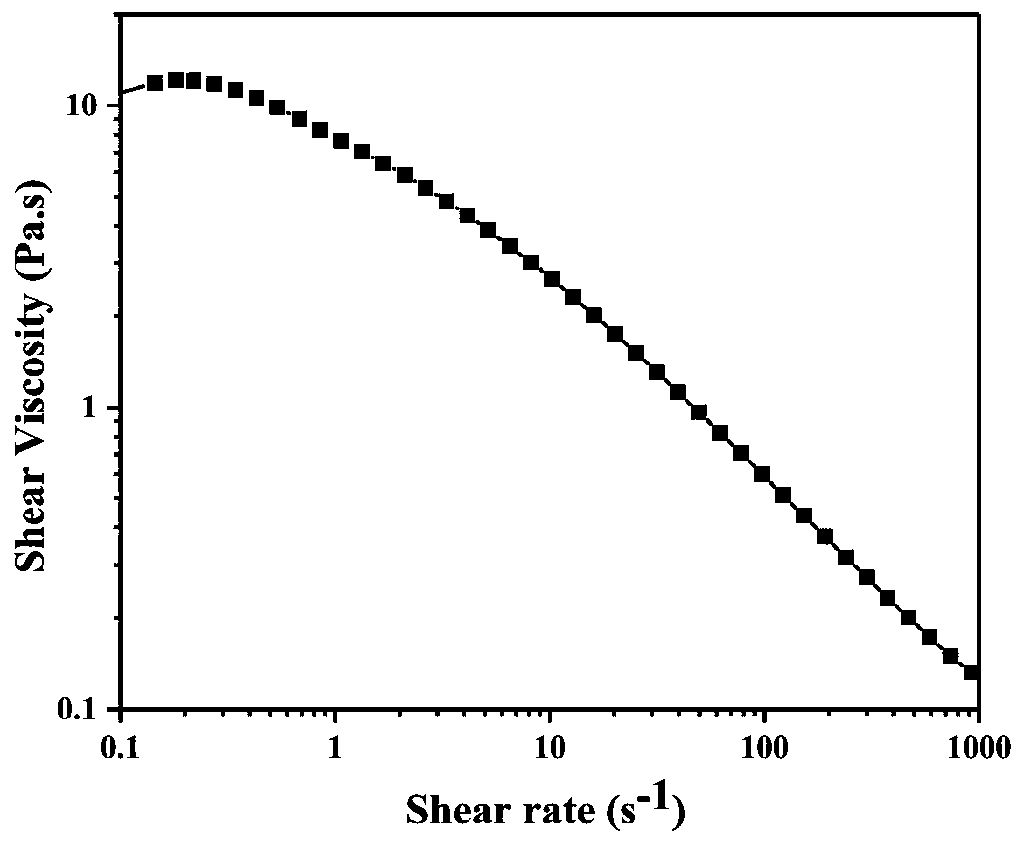

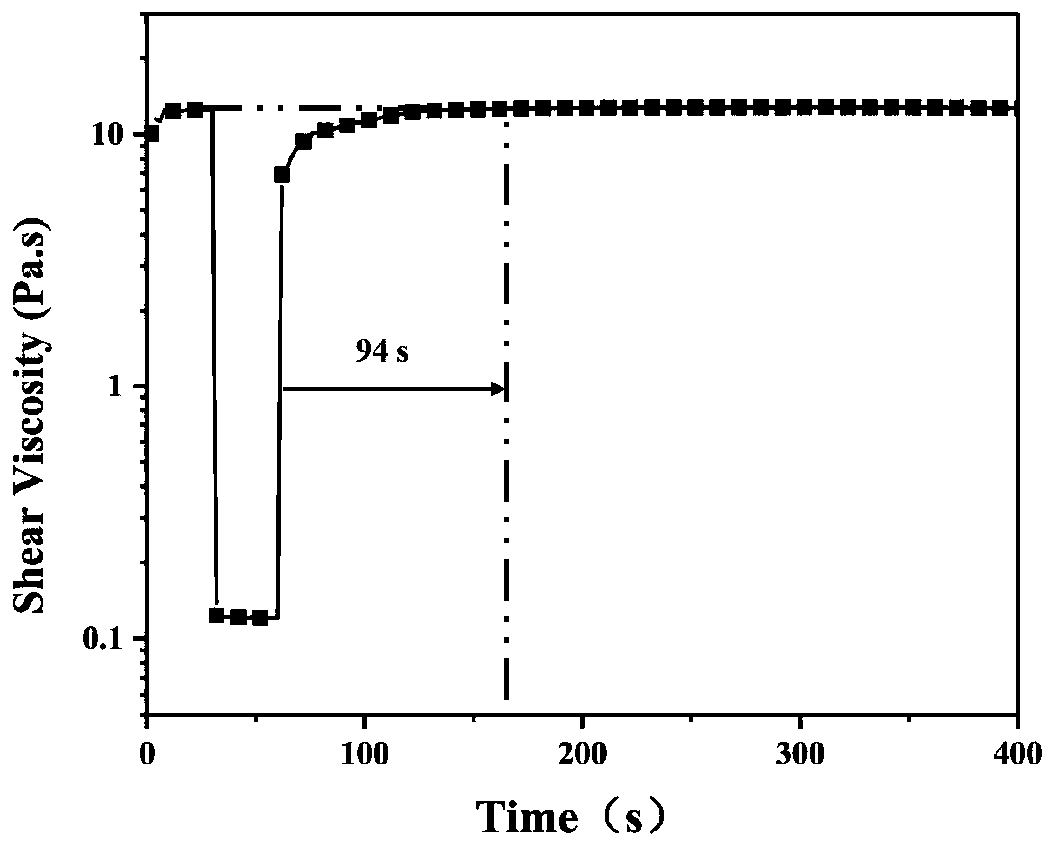

[0036] Slowly add 0.2g of carboxymethylcellulose powder into 19.8g of deionized water solvent, and stir magnetically for 12-24h. When the hydroxyethyl cellulose powder is completely dissolved, add 0.8g of natural purple cabbage pigment powder, 1.6g of glycerin and 0.8g of water-based polyurethane (DF-893), and continue magnetic stirring for 4-6h to carry out pre-dispersion. Finally, use a ball mill to perform ball milling for 60-90 minutes, so that the ink is fully diffused, and the freshness indicator ink is obtained.

[0037] The obtained freshness indicator ink is printed on filter paper by screen printing, and after drying, a layer of silicone oil is sealed. Place the printed instruction label in the dark and let it dry naturally at room temperature for 24 hours.

Embodiment 2

[0039] Slowly add 0.6g of hydroxyethyl cellulose powder into 19.4g of deionized water solvent, and stir magnetically for 12-24h. After the hydroxyethyl cellulose powder is completely dissolved, add 1g of natural purple cabbage pigment powder, 1.8g of glycerin and 1.2g of water-based polyurethane (DF-893), and continue magnetic stirring for 4-6h to carry out pre-dispersion. Finally, use a ball mill to perform ball milling for 60-90 minutes, so that the ink is fully diffused, and the freshness indicator ink is obtained.

[0040] The obtained freshness indicator ink is printed on filter paper by screen printing, and after drying, a layer of silicone oil is sealed. Place the printed instruction label in the dark and let it dry naturally at room temperature for 24 hours.

Embodiment 3

[0042]Slowly add 1g of hydroxyethyl starch powder into 19g of deionized water solvent, and stir magnetically for 12-24h. When the epoxy resin powder is completely dissolved, add 1.2g of natural radish red pigment powder, 2g of glycerin and 1.6g of water-based polyurethane (DF-864) accordingly, and continue magnetic stirring for 4-6h for pre-dispersion. Finally, use a ball mill to perform ball milling for 60-90 minutes, so that the ink is fully diffused, and the freshness indicator ink is obtained.

[0043] The obtained freshness indicator ink is printed on filter paper by screen printing, and after drying, a layer of silicone oil is sealed. Place the printed instruction label in the dark and let it dry naturally at room temperature for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com