Snail essence dry powder and preparation method and application thereof

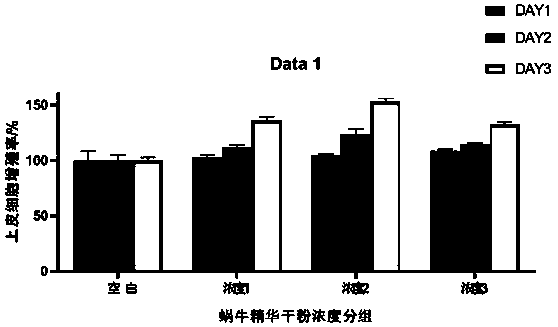

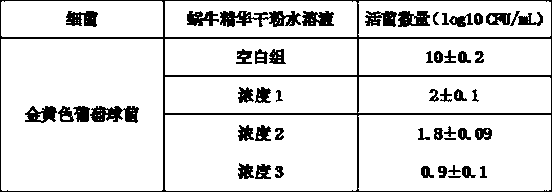

A technology of snail essence and dry powder, which is applied in the field of snail essence dry powder and its preparation, can solve the problems of inconvenient collection of snail mucus, restrictions on the development and utilization of snail-related products, unfavorable preservation, etc., and achieves easy preservation and storage, superior biocompatibility, Strong water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Snail essence dry powder, made by the following steps:

[0036] (1) Add 2 times the weight of snail mucus to pure water to homogenate to obtain homogenate liquid 1, centrifuge the homogenate liquid 1 at a centrifugal speed of 4000r / min for 10 minutes to remove insoluble impurities, then add 3 times the volume of ethanol to precipitate the essence;

[0037] (2) Centrifuge the essence obtained in step (1) at a centrifugal speed of 4000r / min for 10 minutes to obtain precipitate 1, dissolve precipitate 1 in ultra-pure water of 2 times the weight and homogenize for 1 hour to obtain homogenate liquid 2, and pump the homogenate liquid 2 Filtration is obtained by filtration, and the filtrate is concentrated under reduced pressure to 1 / 3 of the original volume to obtain a concentrated solution;

[0038] (3) Centrifuge the concentrated solution obtained in step (2) at a centrifugal speed of 4000r / min for 10 minutes to obtain supernatant 1, add absolute ethanol to the supernatant ...

Embodiment 2

[0042] Snail essence dry powder, made by the following steps:

[0043] (1) Add 1 times the weight of snail mucus to pure water to homogenate to obtain homogenate liquid 1, centrifuge the homogenate liquid 1 at a centrifugal speed of 3000r / min for 15 minutes to remove insoluble impurities, then add 3 times the volume of ethanol to precipitate the essence;

[0044] (2) Centrifuge the essence obtained in step (1) at a centrifugal speed of 3000r / min for 15 minutes to obtain precipitate 1, dissolve precipitate 1 in 1 times the weight of ultrapure water and homogenize for 0.5h to obtain homogenate 2, and homogenate 2 Suction filtration obtains the filtrate, and the filtrate is concentrated under reduced pressure to 1 / 2 of the original volume to obtain a concentrate;

[0045] (3) Centrifuge the concentrated solution obtained in step (2) at a centrifugal speed of 3000r / min for 20 minutes to obtain supernatant 1, add absolute ethanol to supernatant 1 until the concentration of ethanol ...

Embodiment 3

[0049] Snail essence dry powder, made by the following steps:

[0050] (1) Add 3 times the weight of snail mucus to pure water to homogenate to obtain homogenate liquid 1, centrifuge the homogenate liquid 1 at a centrifugal speed of 5000r / min for 5 minutes to remove insoluble impurities, then add 3 times the volume of ethanol to precipitate the essence;

[0051] (2) Centrifuge the essence obtained in step (1) at a centrifugal speed of 5000r / min for 5 minutes to obtain precipitate 1, dissolve precipitate 1 in ultra-pure water of 3 times the weight, and homogenize for 2 hours to obtain homogenate liquid 2, and pump the homogenate liquid 2 Filter to obtain the filtrate, and concentrate the filtrate under reduced pressure to 1 / 5 of the original volume to obtain a concentrated solution;

[0052] (3) Centrifuge the concentrated solution obtained in step (2) at a centrifugal speed of 5000r / min for 3 minutes to obtain supernatant 1, add absolute ethanol to the supernatant 1 until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com