A kind of pulping and papermaking sizing material recycling process

A technology of recycling, pulping and papermaking, which is applied in the field of papermaking, can solve the problems of inconspicuous purification effect and insufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

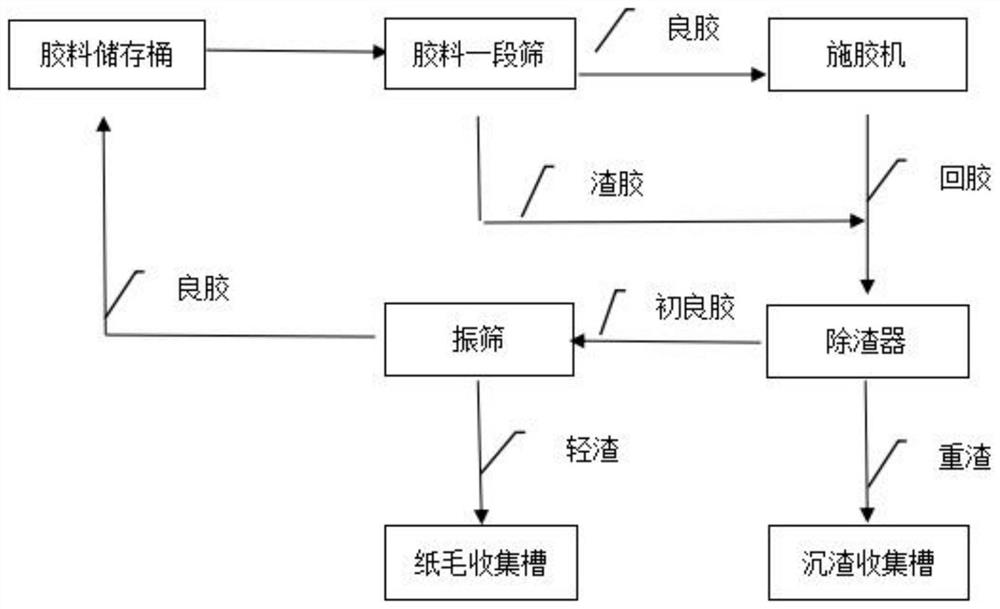

[0056] The sizing material of a certain paper mill is processed in the following steps:

[0057] The first step is to separate the rubber material stored in the rubber material storage barrel through a rubber material first-stage sieve to obtain good rubber and slag rubber, and the good rubber is directly used in the gluing machine;

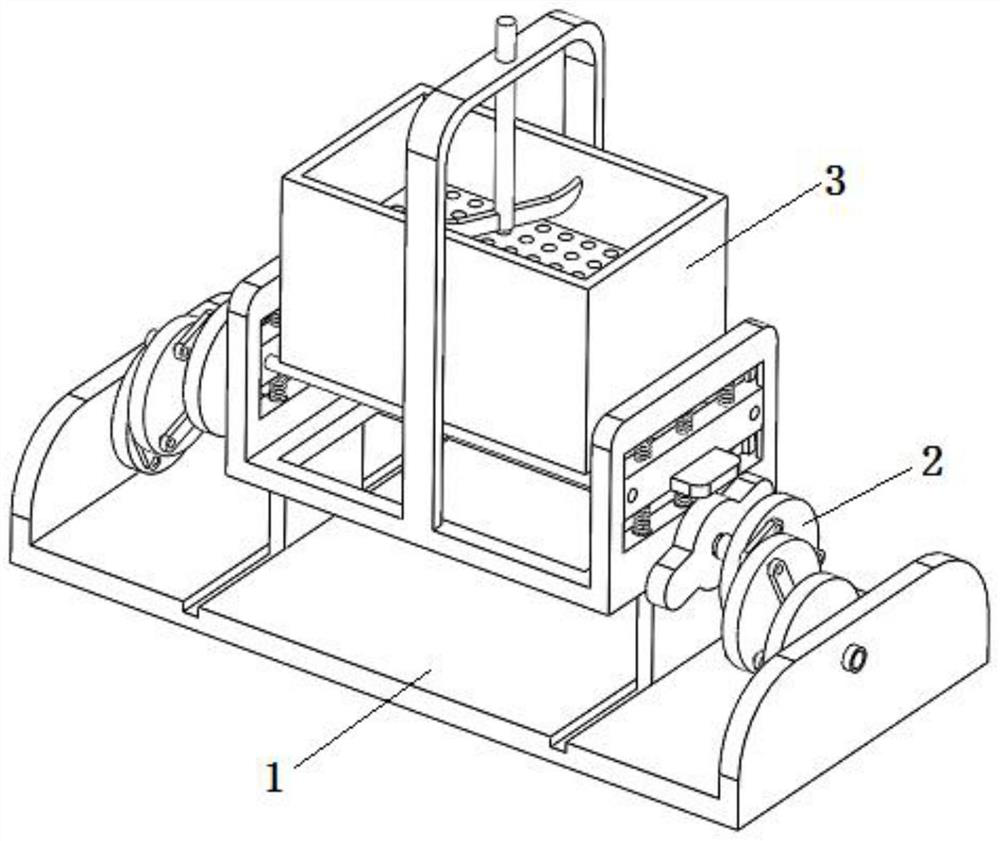

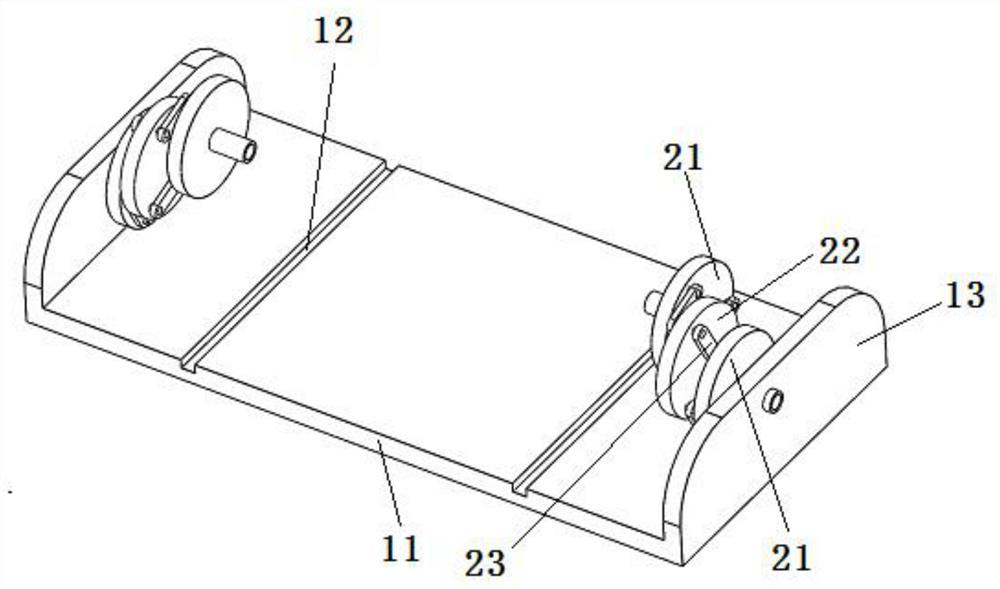

[0058] In the second step, the slag glue obtained through the first-stage sieving of the above rubber material and the back glue produced by the gluing machine enter the filter box 32 of the filter slag removal mechanism together, and the first motor and the second motor are turned on at the same time, and the slag is removed through filtration. The separation function of the mechanism can obtain pre-good glue and heavy slag, and the heavy slag is left on the first filter plate 3201 and the second filter plate 3202, and the heavy slag is collected in the sediment collection tank;

[0059] The third step, the pre-good glue obtained by the filter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com