Preparation method and application of material for adsorption removal of organic matter and ammonia nitrogen

An organic matter, ammonia nitrogen technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of lack of nitrogen removal adsorbents and high operating costs, and achieve the effect of alleviating water shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

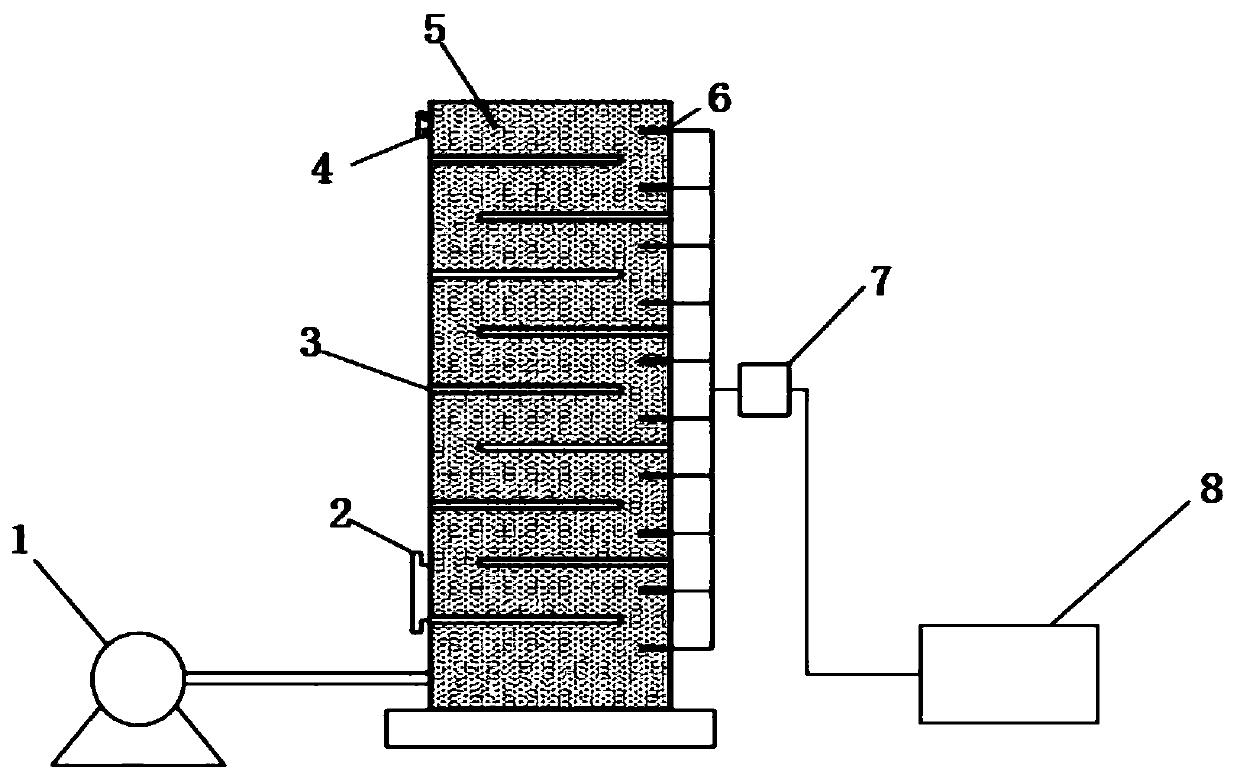

[0028] Such as figure 1 As shown, this embodiment provides a method for preparing a material for adsorbing and removing organic matter and ammonia nitrogen, comprising the following steps:

[0029] 1) select clinoptilolite from natural zeolite and clean it, and wash it three times with distilled water;

[0030] 2) Stir in a high-speed mixer for 30min, then precipitate;

[0031] 3) Remove the upper turbid liquid with a 100 mesh screen;

[0032] 4) drying the cleaned zeolite in an oven at 100° C. for 24 hours;

[0033] 5) Put the dried zeolite into a muffle furnace for pre-activation, burn it at 450°C for 60 minutes, and cool it to room temperature to obtain material A, which is put into a sealed bag for later use;

[0034] 6) Prepare a 5mol / L s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com