Substrate with super-hydrophobic/super-low-adhesion surface and preparation method of substrate

A super-hydrophobic, matrix technology, used in devices for coating liquids on surfaces, special surfaces, manufacturing tools, etc., can solve the problems of narrow range of applicable materials, cumbersome preparation process, poor durability, etc., and achieve precise and controllable preparation process. Simple preparation steps and the effect of a wide range of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

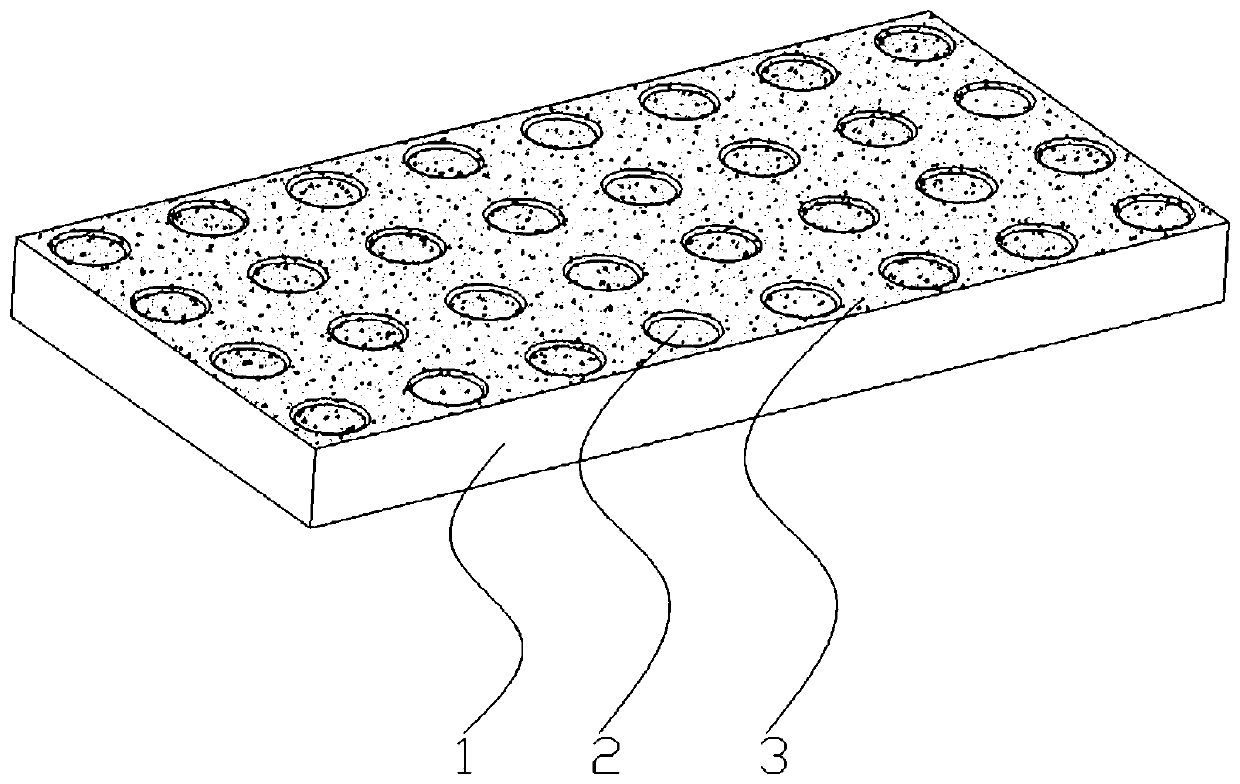

Embodiment 1

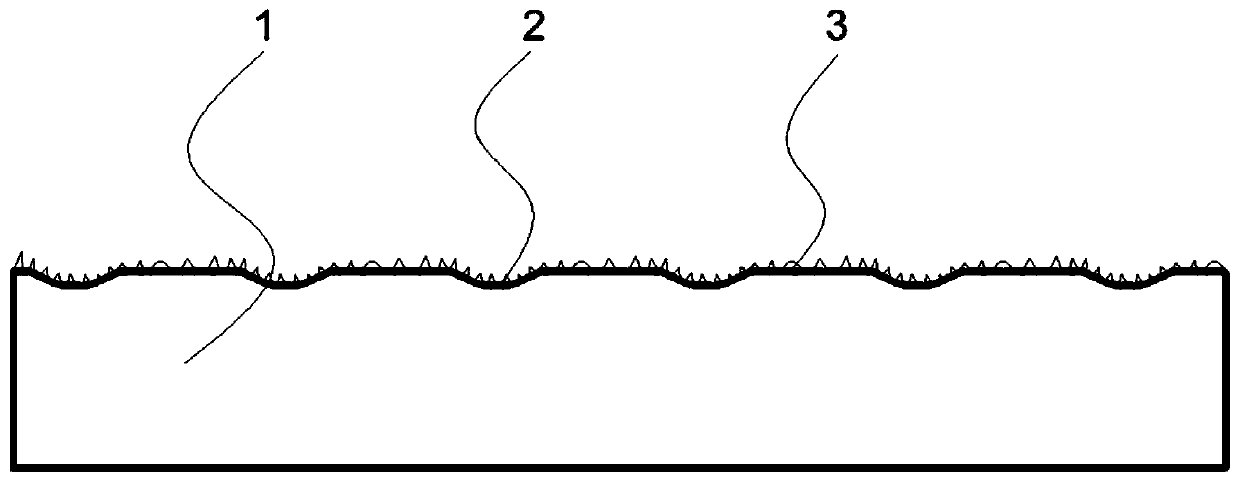

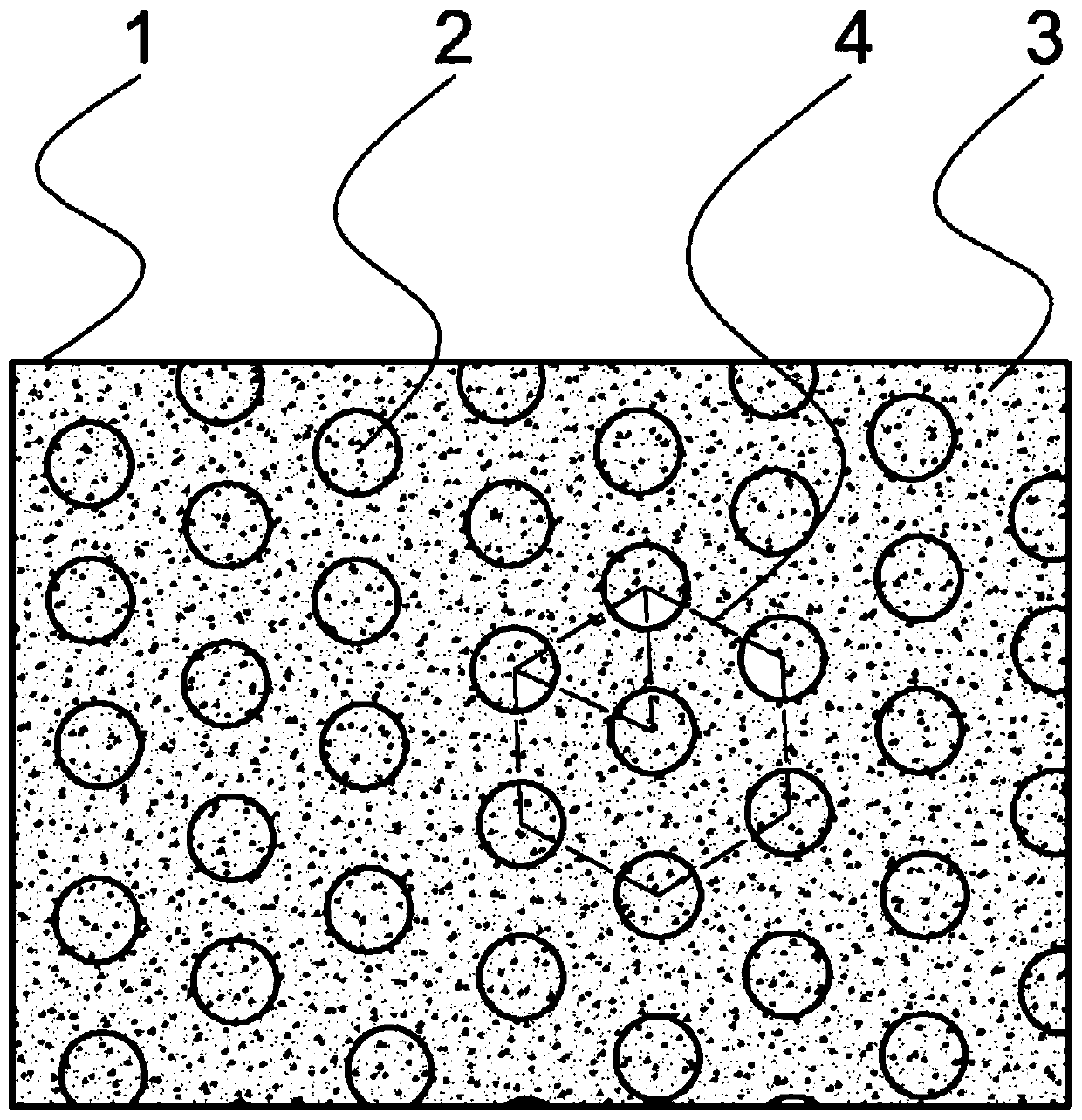

[0050] In this embodiment, a substrate with a super-hydrophobic / ultra-low adhesion surface is made of ordinary glass with a thickness of 2 mm. A uniformly distributed regular hexagonal array of circular pits and randomly distributed flocculent structures are constructed on the glass surface. The diameter of the pit is 10 μm (that is, the pit area is 78.5 μm 2), the maximum depth is 5μm, the pit spacing (ie the side length of the regular hexagonal array) is 24μm; the length of the floc structure is 120nm, the width is 120nm, and the height is 120nm; the glass surface uses 1H, 1H, 2H, 2H-perfluorodecane 1H,1H,2H,2H-perfluorodecyltriethoxysilane solution is 1H,1H,2H,2H-perfluorodecyltriethoxysilane The mixture with anhydrous ethanol mass ratio of 1:55.

[0051] The above-mentioned preparation method of the substrate with super-hydrophobic / ultra-low adhesion surface comprises the following steps:

[0052] Step a: ultrasonically clean the ordinary glass, and after cleaning, dry i...

Embodiment 2

[0057] A substrate with a super-hydrophobic / ultra-low adhesion surface in this embodiment is a silicon wafer with a thickness of 1 mm. A uniformly distributed square array of circular pits and randomly distributed flocculent structures are constructed on the surface of the silicon wafer. The diameter of the pit is 8.4 μm (that is, the pit area is 55 μm 2 ), the maximum depth is 0.5 μm, and the pit spacing (ie, the side length of the square array) is 18 μm; the surface of the silicon wafer is also constructed with a randomly distributed flocculent structure with a length of 50 nm, a width of 50 nm, and a height of 50 nm; The surface is modified with 1H,1H,2H,2H-perfluorodecyltriethoxysilane solution with low surface energy, 1H,1H,2H,2H-perfluorodecyltriethoxysilane solution is 1H,1H, The mixture of 2H,2H-perfluorodecyltriethoxysilane and absolute ethanol with a mass ratio of 1:80.

[0058] The above-mentioned preparation method of the substrate with super-hydrophobic / ultra-low...

Embodiment 3

[0064] A substrate with a super-hydrophobic / ultra-low adhesion surface in this embodiment is an aluminum sheet with a thickness of 2 mm, and a uniformly distributed regular hexagonal array of circular pits and randomly distributed flocculent structures are constructed on the surface of the aluminum sheet. , the diameter of the pit is 12.3 μm (that is, the pit area is 119 μm 2 ), the maximum depth is 10μm, the pit spacing (that is, the length of the regular hexagonal array) is 30μm; the length of the floc structure is 200nm, the width is 200nm, and the height is 200nm; the surface of the aluminum sheet uses 1H, 1H, 2H, 2H-perfluoro Decyltriethoxysilane solution for low surface energy modification, 1H,1H,2H,2H-perfluorodecyltriethoxysilane solution is 1H,1H,2H,2H-perfluorodecyltriethoxy The mass ratio of silane and absolute ethanol is 1:40.

[0065] The above-mentioned preparation method of the substrate with super-hydrophobic / ultra-low adhesion surface comprises the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com