Device and method for laser real-time removal of surface oxide scale in additive manufacturing process of metal component

A technology of additive manufacturing and metal components, applied in the field of additive manufacturing, can solve problems that have not been seen yet, and achieve the effects of avoiding adverse effects, open working environment, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

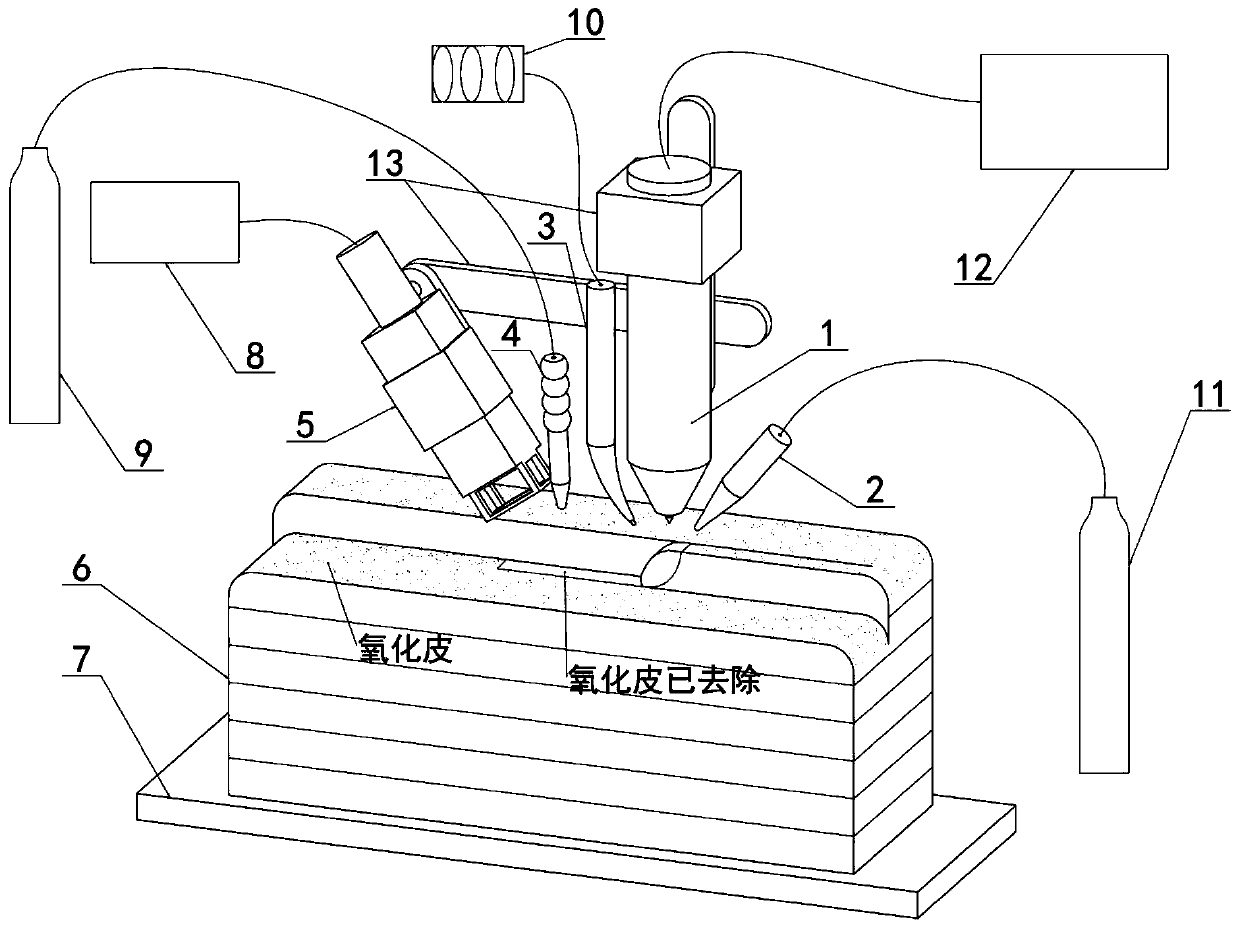

[0039] Take wire-feeding TIG arc additive manufacturing of 2219 aluminum alloy large-scale components as an example, such as figure 1 As shown, the side blowing shielding gas and side wire feeding method are adopted, the feeding nozzle is the wire feeding nozzle, the additive deposition heat source is the welding machine, the additive deposition head is the welding gun, and the laser is the Nd:YAG laser, including the following steps:

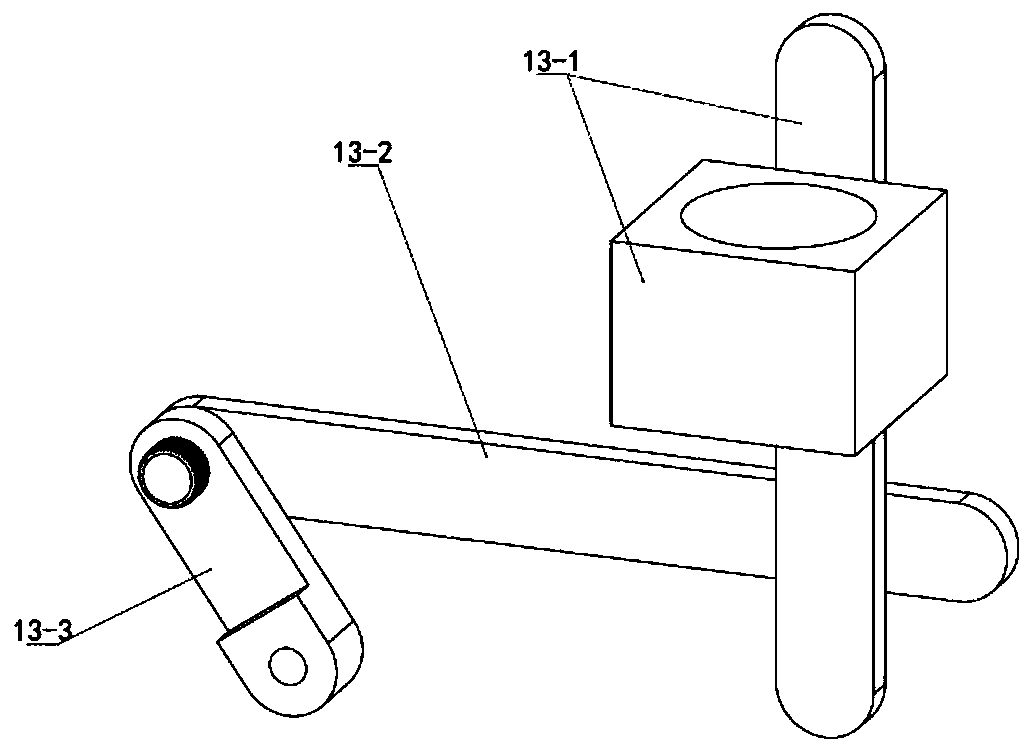

[0040] Step 1: Remove the oxide scale and dirt on the surface of the 6061 substrate with a steel brush, and fix it; adjust the distance between the laser cleaning head 5 and the welding torch 1 and the distance between the laser cleaning head 5 and the additive deposition surface through the screw nut of the connection mechanism 13. Height; adjust the angle between the laser beam and the axis of the welding torch 1 through the knob of the connection mechanism 13; the laser cleaning head 5 is fixed in front of the moving direction of the welding...

Embodiment 2

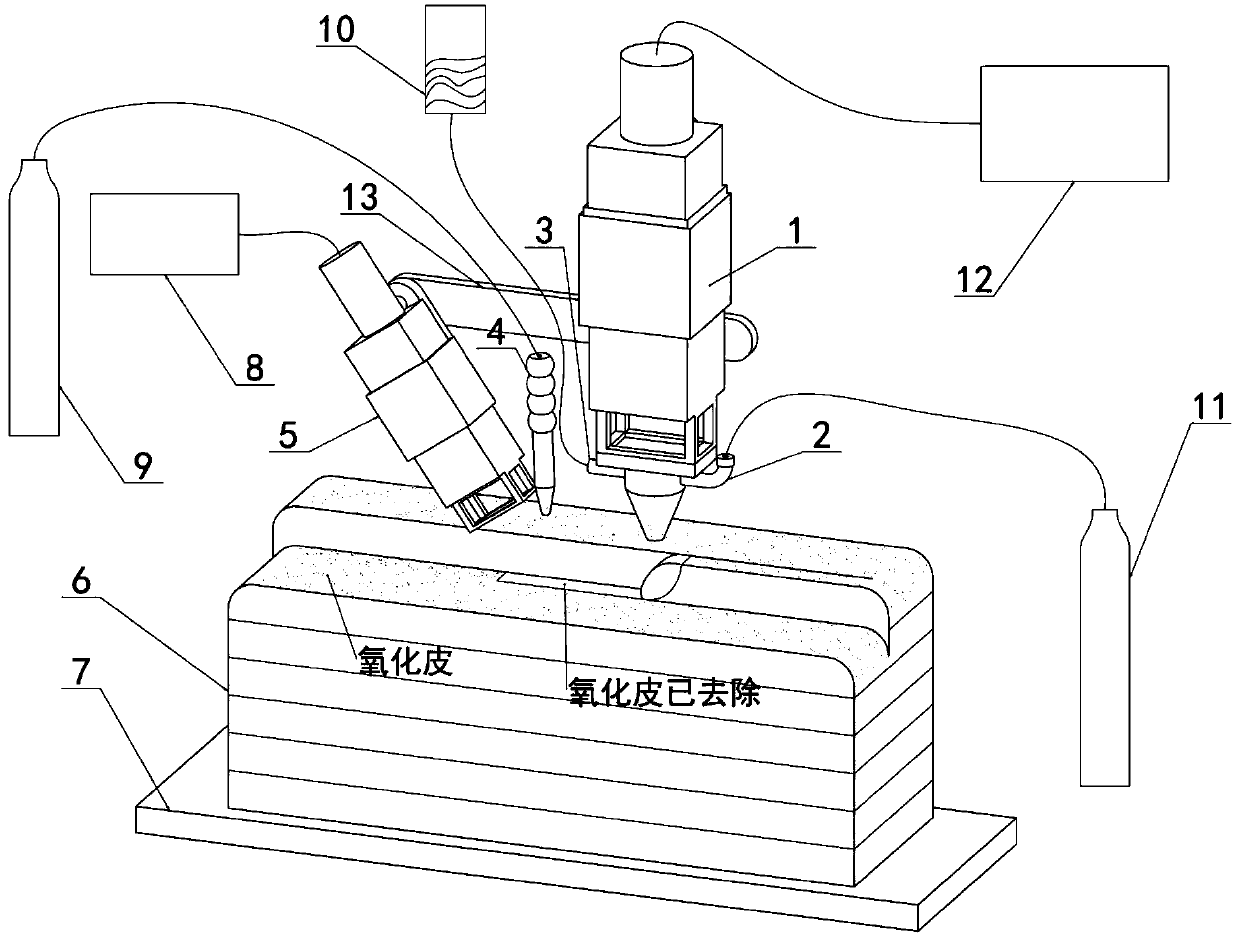

[0045] Take powder-feeding laser additive manufacturing of TC4 titanium alloy large-scale components as an example, such as figure 2 As shown, the coaxial shielding gas and coaxial powder feeding method are adopted, the feeding nozzle is the powder feeding nozzle, the additive deposition heat source is a YLS4000 fiber laser, the additive deposition head is a laser welding head, and the laser is a Nd:YAG laser, including the following steps :

[0046] Step 1: Use a steel brush to remove the oxide scale and dirt on the surface of the TA0 substrate and fix it; adjust the distance between the laser cleaning head 5 and the laser welding head 1 and the laser cleaning head 5 and the additive deposition through the screw nut of the connecting mechanism 13 Adjust the angle between the laser beam and the axis of the welding torch 1 through the knob of the connecting mechanism 13; the laser cleaning head 5 is fixed in front of the moving direction of the laser welding head 1; turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com