Mesoporous hollow carbon spheres and production and application in electromagnetic absorption thereof

A hollow carbon sphere, mesoporous technology, applied in nano carbon, electrical components, magnetic field/electric field shielding and other directions, can solve the problems of low yield, cumbersome steps, etc., and achieve the effect of low production cost, simple process and reduced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

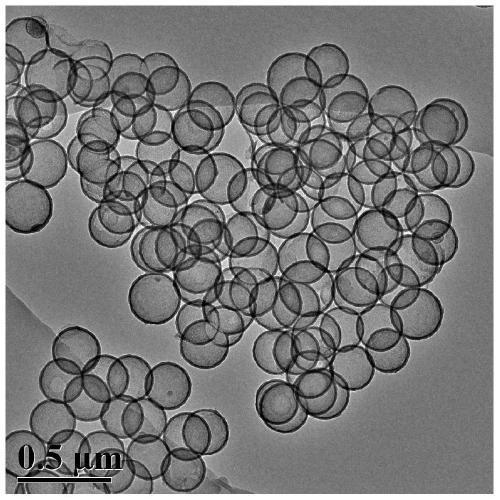

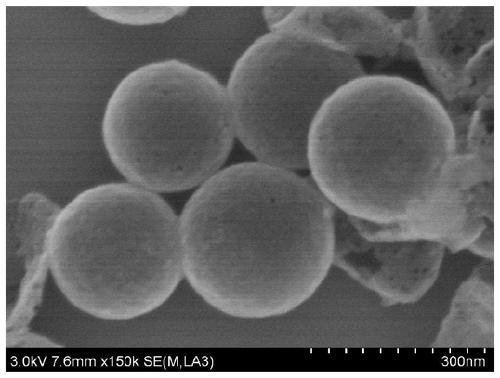

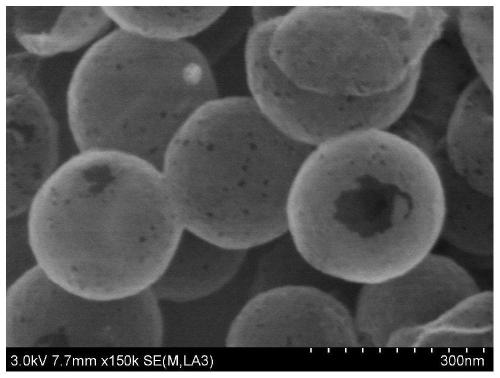

[0029] Step 1: Take 50ml of ethanol, 7ml of distilled water, 3ml of ammonia water, and 2ml of tetraethyl orthosilicate in a beaker and stir for 30 minutes. At this time, the solution appears milky white. Add 0.2g of resorcinol and 0.5ml of formaldehyde with a volume fraction of 37%. Stir for 10 hours to obtain an orange solution. After centrifugation and washing, dry at 60°C to obtain an orange powder. Carbonize the powder in an environment at 850°C for 6 hours and a heating rate of 2°C / min to obtain carbon-coated SiO 2 Composite material, then add 3g NaOH to remove SiO 2 , to obtain hollow carbon spheres.

[0030] Step 2: Dissolve 30 mg of the hollow carbon spheres obtained in Step 1 in 10 mL of HF solution (30% by volume), and then sonicate for 10 min to make them uniformly dispersed.

[0031] Step 3: The mixed dispersion obtained in step 2 was stirred at a constant temperature of 50°C for 3h, and the remaining carbon material in the mixed dispersion was collected by suctio...

Embodiment 2

[0033] Step 1: Take 30ml of ethanol, 4mL of distilled water, 2ml of ammonia water, and 1ml of tetraethyl orthosilicate, put them in a beaker and stir for 20 minutes. At this time, the solution is milky white. Add 0.5g of resorcinol and 2mL of formaldehyde with a volume fraction of 37%. , stirred for 8 hours to obtain an orange solution, dried at 70°C after centrifugal washing to obtain an orange powder, and carbonized the powder in an environment of 850°C for 3 hours and a heating rate of 10°C / min to obtain carbon-coated SiO 2 Composite material, then add 2g NaOH to remove SiO 2 , to obtain hollow carbon spheres.

[0034] Step 2: Dissolve 20 mg of the hollow carbon spheres obtained in Step 1 in 50 mL of HF solution (30% by volume), and then sonicate for 20 min to make them uniformly dispersed.

[0035] Step 3: The mixed dispersion obtained in step 2 was stirred at a constant temperature of 60°C for 4 hours, the remaining carbon material in the mixed dispersion was collected b...

Embodiment 3

[0037] Step 1: Take 10ml of ethanol, 2mL of distilled water, 1ml of ammonia water, and 2ml of tetraethyl orthosilicate, put them into a clean beaker, stir for 20min, the solution is milky white at this time, add 0.1g of resorcinol, the volume fraction of 1mL is 37% formaldehyde, stirred for 8 hours to obtain an orange solution, dried at 60°C after centrifugal washing to obtain an orange powder, and carbonized the powder in an environment of 850°C for 5 hours at a heating rate of 5°C / min to obtain a carbon coated Coated SiO 2 Composite material, then add 1g NaOH to remove SiO 2 , to obtain hollow carbon spheres.

[0038] Step 2: Dissolve 20 mg of the hollow carbon spheres obtained in Step 1 in 70 mL of HF solution (30% by volume), and then sonicate for 20 min to make them uniformly dispersed.

[0039] Step 3: The mixed dispersion obtained in step 2 was stirred at a constant temperature of 60°C for 2 hours, and the remaining carbon material in the mixed dispersion was collecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Minimum reflection loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com