Single-layer wrinkled graphene and its preparation method and use

A graphene and wrinkle technology, which is applied in the field of single-layer wrinkled graphene and its preparation, can solve the problems of needing substrate templates, high dependence, and high energy consumption of high-temperature thermal reduction, achieving simple and efficient methods, improving production efficiency, and suppressing stacking. stack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the preparation of a kind of monolayer wrinkled graphene

[0046] (1) The process of chemically oxidizing, exfoliating and centrifuging natural graphite flakes to obtain a graphene oxide dispersion, mixing 500 mL of a 1.0 mg / mL graphene oxide dispersion with 25 mL of concentrated ammonia (25%-28%), and heating To 70°C, stir and reflux for 0.5h;

[0047] (2) Centrifuge the solution after alkali washing at 10,000 rpm for 0.5 h to obtain a solid precipitate, wash with water and then centrifuge, and disperse the centrifuged solid in 500 mL of 0.01M hydrochloric acid to obtain a mixed solution;

[0048] (3) Heat the mixed solution to 70°C, stir and reflux for 0.5h, and then perform centrifugation at 10,000 rpm for 0.5h after cooling, wash the centrifuged solid with water and then centrifuge, and redisperse the centrifuged solid in water to obtain 2.5mg / mL graphene oxide dispersion.

[0049] (4) Mix the graphene oxide dispersion with ascorbic acid, the graphen...

Embodiment 2

[0050] Embodiment 2: the preparation of a kind of monolayer wrinkled graphene

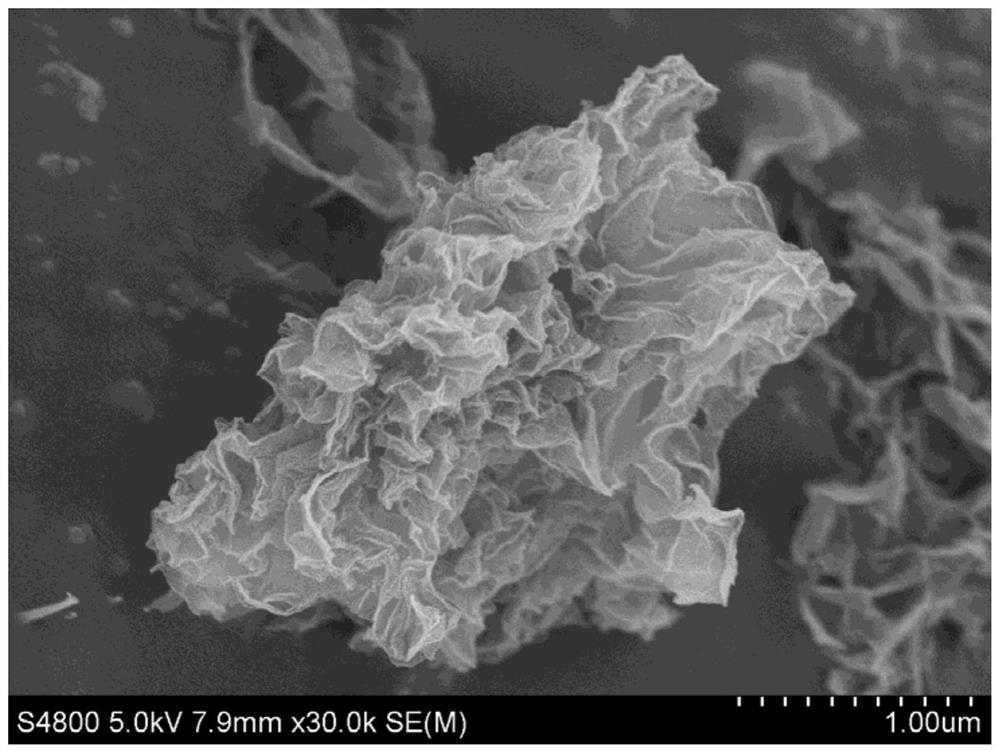

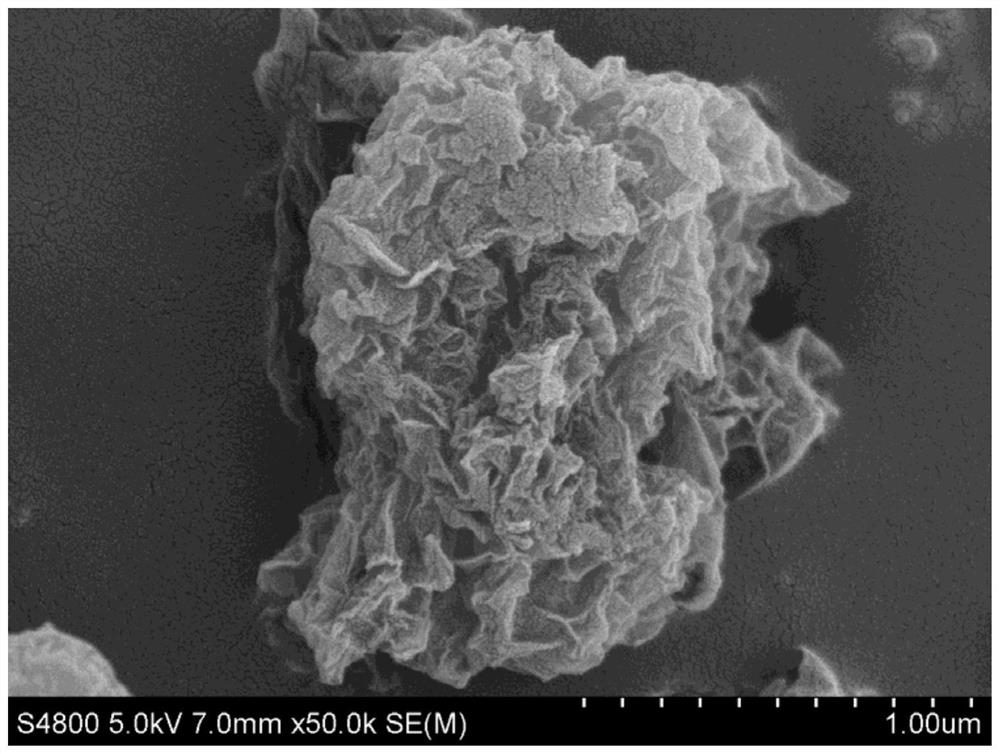

[0051] The difference from Example 1 is that the concentration of the graphene oxide dispersion in the preparation step of the graphene oxide alkaline dispersion solution is 2.0 mg / mL. Obtained graphene was observed by scanning electron microscope, and its surface morphology was as follows: figure 2 It can be seen from the figure that the surface of the graphene powder is highly wrinkled and distributed in a single layer.

Embodiment 3

[0052] Embodiment 3: the preparation of a kind of monolayer wrinkled graphene

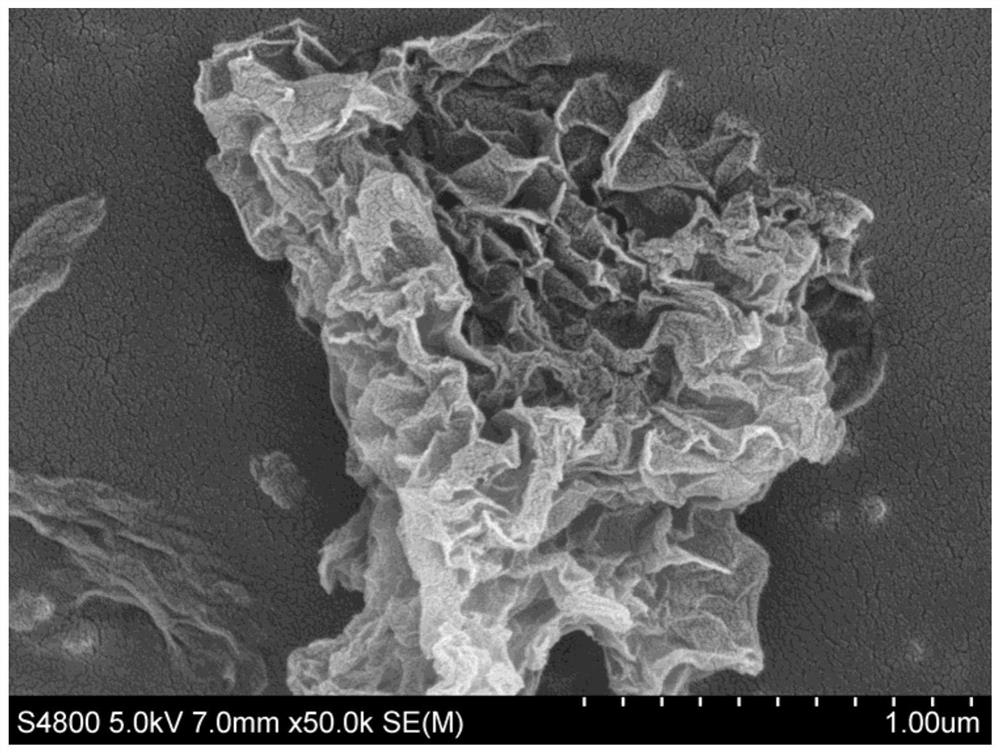

[0053] The difference from Example 1 is that the ammonia water in the preparation step of the graphene oxide alkaline dispersion solution is replaced by sodium hydroxide. Obtained graphene was observed by scanning electron microscope, and its surface morphology was as follows: image 3 It can be seen from the figure that the surface of the graphene powder is highly wrinkled and distributed in a single layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com