2D/2D photocatalysis-photothermal composite material as well as preparation method and application thereof

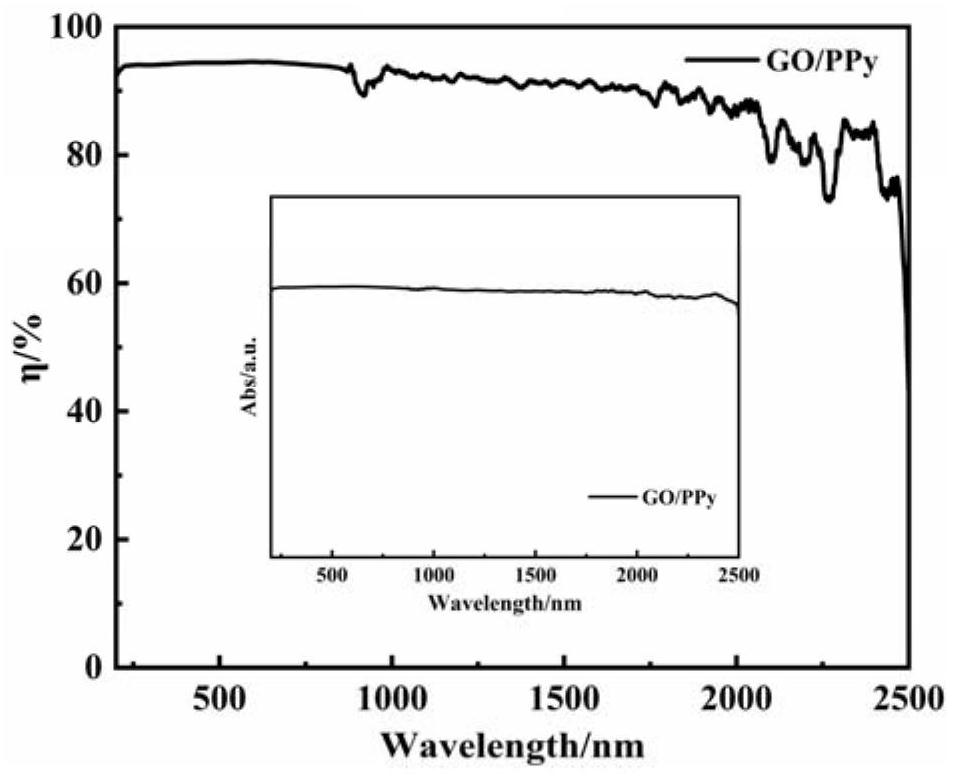

A composite material and photocatalytic technology, applied in the field of nano-catalytic material preparation, can solve the problems of single function and secondary pollution of water treatment materials, and achieve the effects of excellent photocatalytic performance, low cost and high photo-generated carrier mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

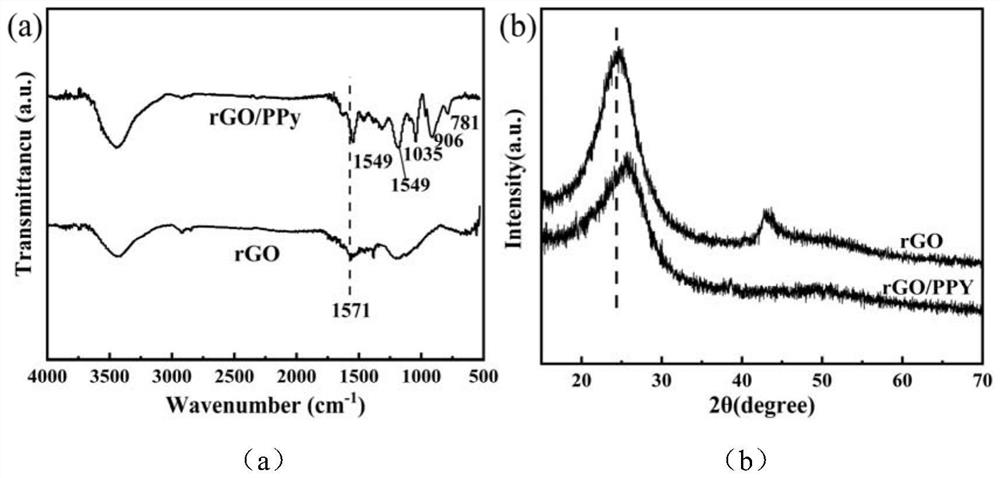

[0032] The present invention disclosed a 2D / 2D (two-dimensional / two-dimensional) photocatalytic-optical composite material and its preparation method. The preparation method includes the following steps:

[0033]Step 1, at room temperature conditions, the oxide graphene ultrasonic is dispersed into the derived water. Among them, the concentration of graphene is 0.5 to 10 mg / ml, and the diversified liquid of oxygenne is obtained; the ultrasonic dispersing time is 10-30min.

[0034] Step 2, add pyricine monomer to the decentralized liquid of oxide, the drip speed is 20 to 100 drops / min, and the purity of the pyrine monomer of the drip is 95.0 % -99.9 %; The liquid is always stirred in the ice bath, stirring under the action of magnetic rotor, the stirring rate is 100 to 500R / min, and the stirring time is 5 to 30min. Put the prepared hybrid solution into the polytetrafluoroethylene reactor, put it in the oven to the reaction, the reaction time is 3-12 hours, the reaction temperature ...

Embodiment 1

[0041]

[0042]

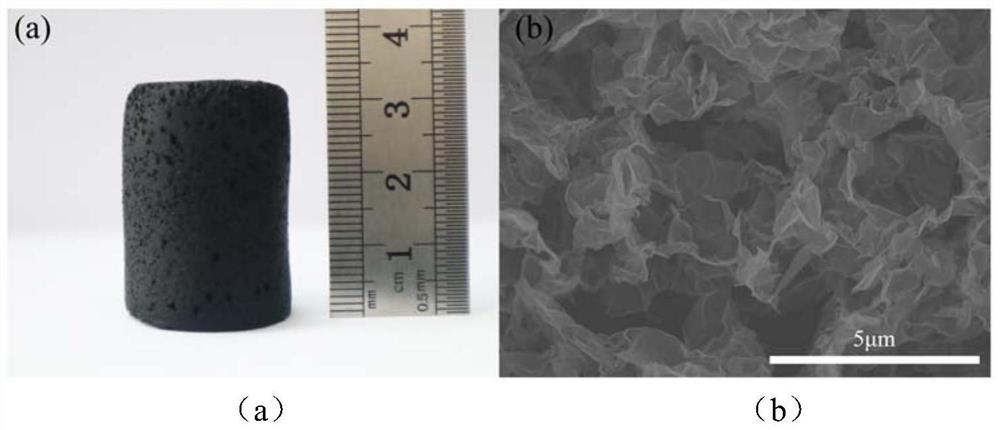

[0043] Under room temperature conditions, each component is taken according to the proportion described in the present invention. First, the 1mg / mL oxidation graphene ultrasound is scattered for 10 minutes to remove the ionic water to form oxygenyne decentralized liquid. Stir under the action of a magnetic rotor in the bath pot. Next, add 0.5mol / L pyrick to a drip to add a drop of 30 drops per minute to the garty oxide decentralized liquid. During the drip process, the graphene dispersing solution is always in the ice bath, the role of magnetic rotor, the role of magnetic rotor Stir at a speed of 500R / min for 30 minutes to get the front -drive liquid. Put the prepared solution in a polytetrafluoroethylene reactor, place it in the oven, and react at 200 ° C for 10h to make RGO / PY hydrogel.

[0044] Under room temperature conditions, soak the RGO / PY hydrogel 1mol / L FeCl 3 · 6H 2 In the O solution, the reaction is 15h at 8 ° C. Washed the income of the water gel...

Embodiment 2

[0046]

[0047] Under room temperature conditions, each component is taken according to the proportion described in the present invention. First, the 3mg / ml graphene ultrasound is scattered in 15 minutes to remove the ionic water to form a graphene dispersing solution. In the ice bath, stir under the action of a magnetic rotor. Next, add the 1.5mol / L pyri -pyrone to add a drop of 30 drops per minute to add to the graphene dispersing solution. During the drip process, the graphene decentralized liquid is always in the ice bath, and the role of magnetic rotor is in a magnetic rotor. Stir at a speed of 800R / min for 30 minutes to get the front -drive liquid. Put the prepared solution in a polytetrafluoroethylene reactor, place it in the oven, and react at 150 ° C for 8h to make RGO / PY hydrogel.

[0048] Under room temperature conditions, soak the RGO / PY hydrogel soak 2mol / L in ammonium sulfate solution, react at 10 ° C for 12h, clean the income of the water gel with ethanol and deod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com