Anaerobic ammonia oxidation-couped denitrification composite denitrification system and quick starting method

A combination of anaerobic ammonium oxidation and anaerobic ammonium oxidation technology, applied in the field of biological nitrogen removal, to achieve the effect of low demand, high nitrogen removal effect, and high total nitrogen removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

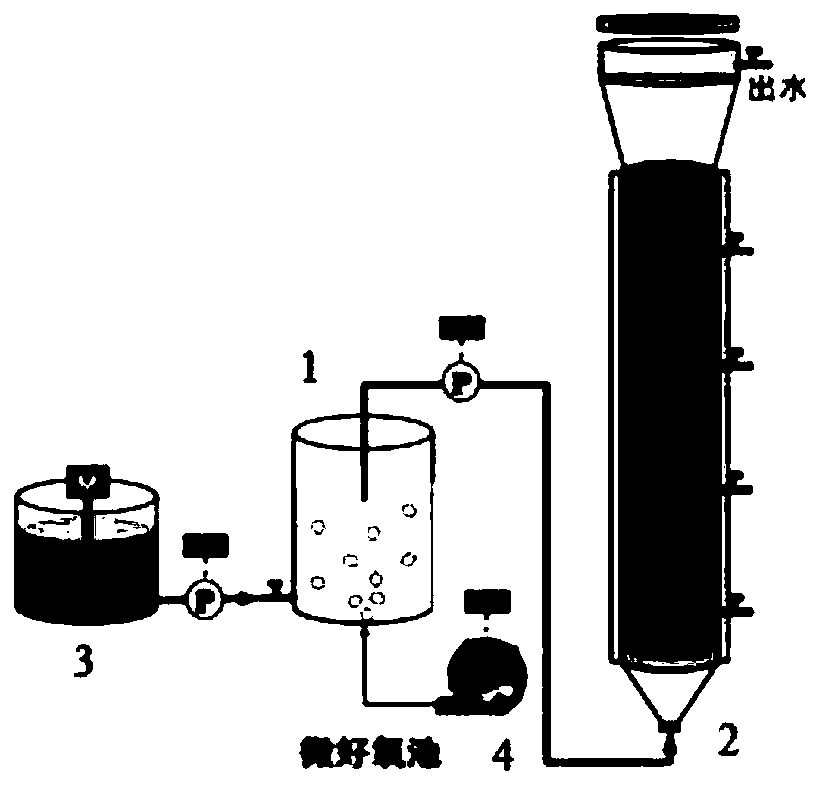

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

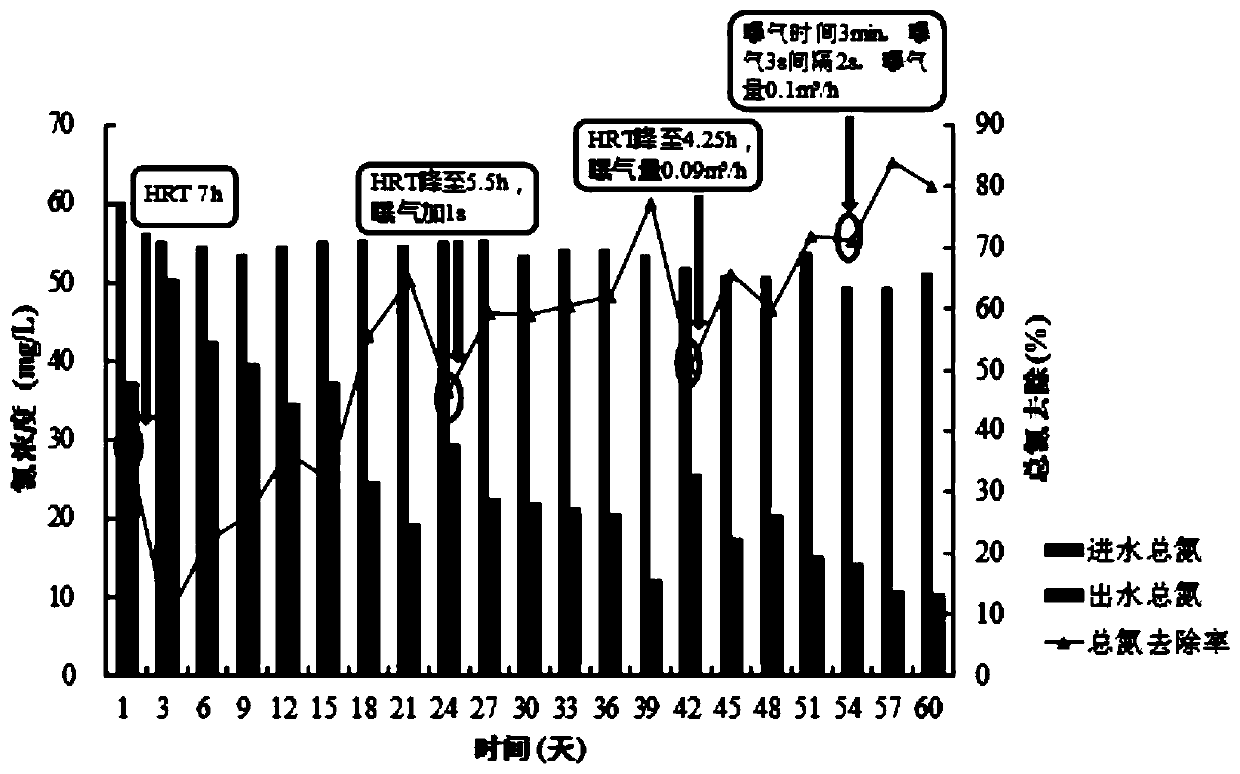

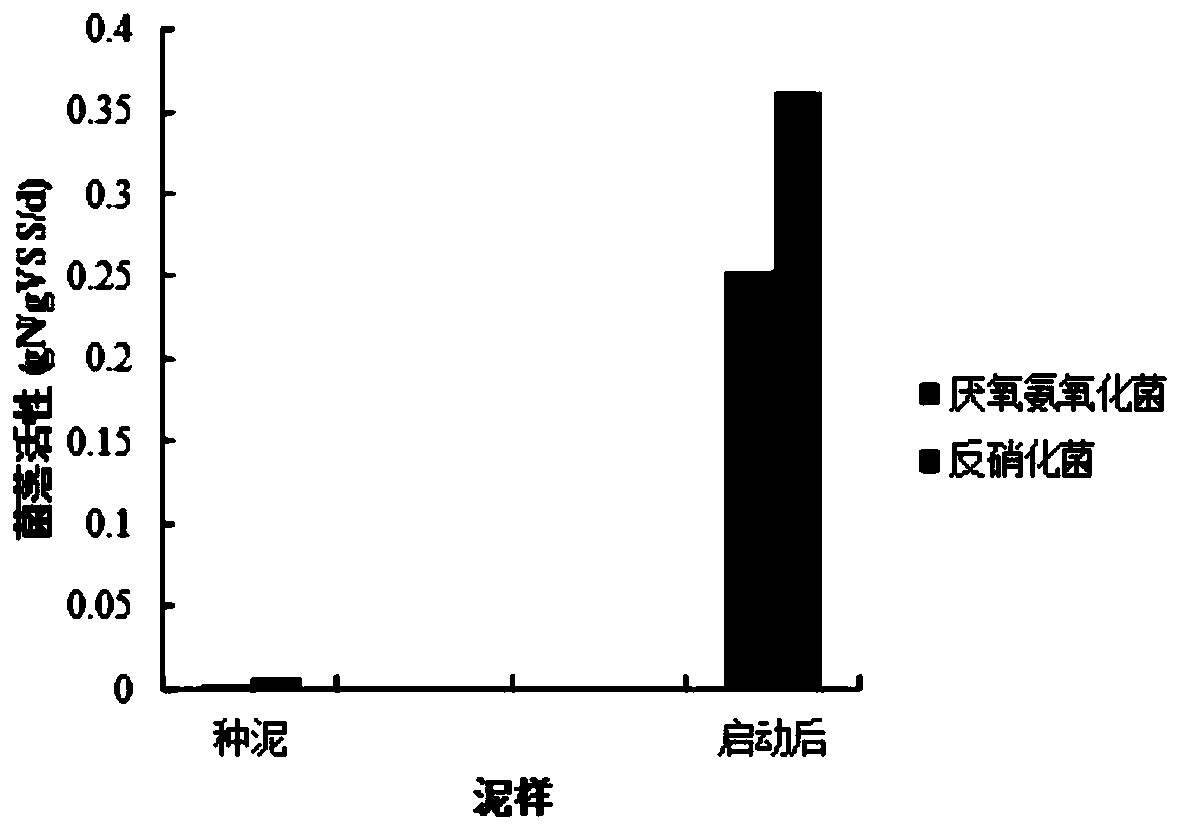

[0030] The present invention proposes an anaerobic ammonium oxidation coupled denitrification compound denitrification system and a quick start-up method. The system mainly includes two parts: anoxic device and anaerobic device. The specific operation process is as follows:

[0031] The first step: set the initial hydraulic retention time and aeration time and interval, so as to determine according to the matrix composition (ammonium bicarbonate, potassium dihydrogen phosphate, sodium bicarbonate, anhydrous magnesium chloride, anhydrous calcium chloride, other trace elements) Nitrogen load;

[0032] Step 2: Determine the air flow of the aeration pump according to the set aeration interval and time, and use the gas flow meter to monitor in real time;

[0033] Step 3: Select the appropriate sludge (the end of the anoxic tank of the urban sewage plant) as the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com