A kind of red mud-based asphalt powder and its preparation method and application

A technology based on asphalt powder and red mud is applied to building components, building insulation materials, buildings, etc. It can solve the problems of complicated process, limited crushing particle size, and high cooling tower, and achieves simple production process, increased contact area, and improved The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In yet another specific embodiment of the present invention, the preparation method of the above-mentioned red mud-based asphalt powder is provided, and the preparation method comprises:

[0034] Sieve the red mud and zeolite powder respectively, and set aside;

[0035] Heat the base asphalt to a liquid state and maintain it at the heating temperature, add sieved zeolite powder in proportion to make the base asphalt micro-foam; then add the sieved red mud in proportion, and stir well , cooled to normal temperature to obtain a solid mixture;

[0036] Crush the solid mixture to a powder.

[0037] In yet another embodiment of the present invention, the red mud is passed through a 2mm standard sieve; the zeolite powder is passed through a 0.075mm standard sieve;

[0038] In yet another specific embodiment of the present invention, the heating temperature is controlled at 140-160°C;

[0039] In yet another specific embodiment of the present invention, the grinding process...

Embodiment

[0044] Preparation:

[0045] (1) Sintering method red mud or Bayer method red mud passes through a 2mm standard sieve for use;

[0046] (2) zeolite powder is crossed 0.075mm standard sieve, standby;

[0047] (3) Heat No. 70 base asphalt to 140-160°C until it is in a liquid state, and set aside.

[0048] (4) Maintain the temperature condition, add zeolite powder in proportion to make the matrix asphalt micro-foam; then add red mud in proportion and stir well, pour it into a cooling container to cool at room temperature, and set aside;

[0049] (5) Use a grinder to grind the asphalt-red mud mixture cooled to normal temperature into powder, the grinding time is 10-15s, and the final product fineness of red mud-based asphalt powder is about 120 mesh, and the water content is less than 3%.

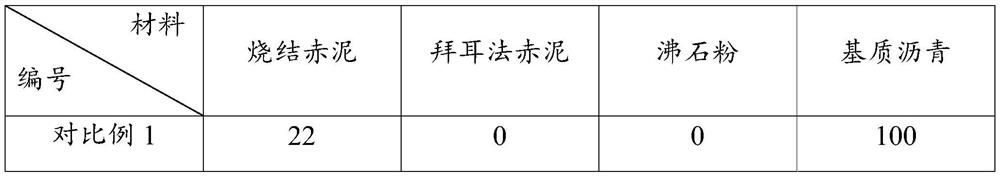

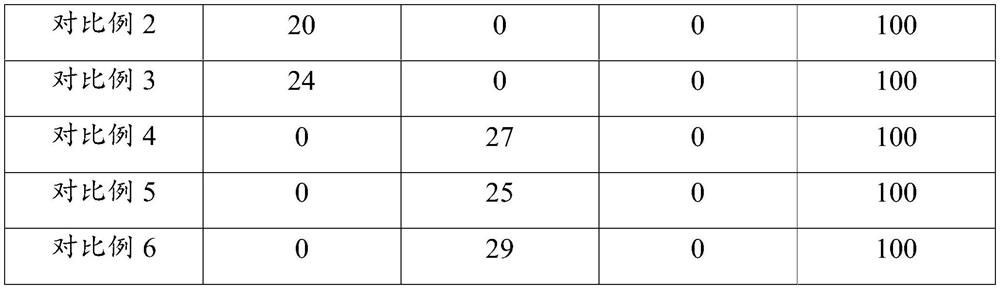

[0050] Wherein, the weight ratio of each raw material is shown in the following table:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com