Asphalt pavement heat-reflecting coating and preparation method thereof

A heat-reflective coating, asphalt pavement technology, applied in the direction of reflection/signal coating, coating, road, etc., to achieve the effect of convenient construction, reduced drop, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]

[0044] The preparation method of asphalt pavement heat reflective coating of the present invention, it comprises the steps:

[0045] (1), adding nano-titanium dioxide into the first water-based epoxy resin and stirring to obtain the first mixture;

[0046] (2), adding nano silicon dioxide into the first mixture and stirring to obtain the second mixture;

[0047] (3), adding iron oxide red, dispersant and matting agent into the second mixture in turn and stirring to obtain the third mixture;

[0048] (4), the second water-based epoxy resin is added to the third mixture and stirred to obtain a water-based epoxy resin coating;

[0049] (5) Brush the water-based epoxy resin paint on the surface of the asphalt pavement to obtain a coating. Within 10 minutes after the brushing is completed, spread the anti-slip agent on the surface of the coating and shape it.

[0050] Wherein, in step (1), the stirring time may be 2±0.5 min, preferably 2 min.

[0051] In step (2), the...

Embodiment 1

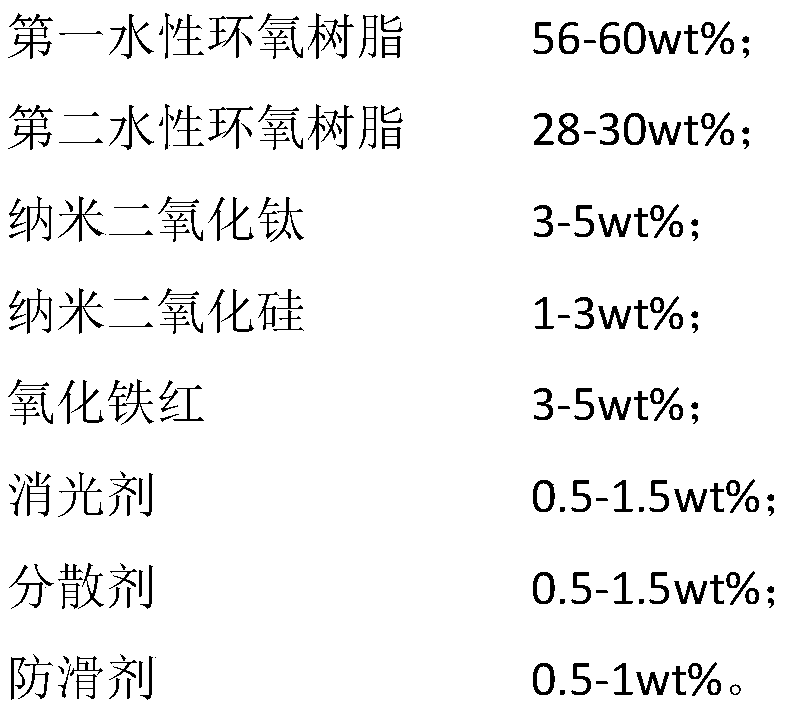

[0056] The asphalt pavement heat reflective coating of the present embodiment comprises the following components:

[0057]

[0058]

[0059] The preparation method of the asphalt pavement heat reflective coating of the present embodiment comprises the following steps:

[0060] (1), first add 94g of nano-titanium dioxide into 1000g of the first water-based epoxy resin and fully stir for 2min to obtain the first mixture;

[0061] (2), then add 47g of nano silicon dioxide into the first mixture and fully stir for 1min to obtain the second mixture;

[0062] (3), then add 94g of red iron oxide, 35.25g of dispersant and 23.5g of matting agent into the second mixture in sequence and fully stir for 2min to obtain the third mixture;

[0063] (4), finally the second water-based epoxy resin of 500g is added in the third mixture and fully stirred for 2min to obtain a uniformly dispersed water-based epoxy resin coating;

[0064](5), the water-based epoxy resin coating is evenly bru...

Embodiment 2

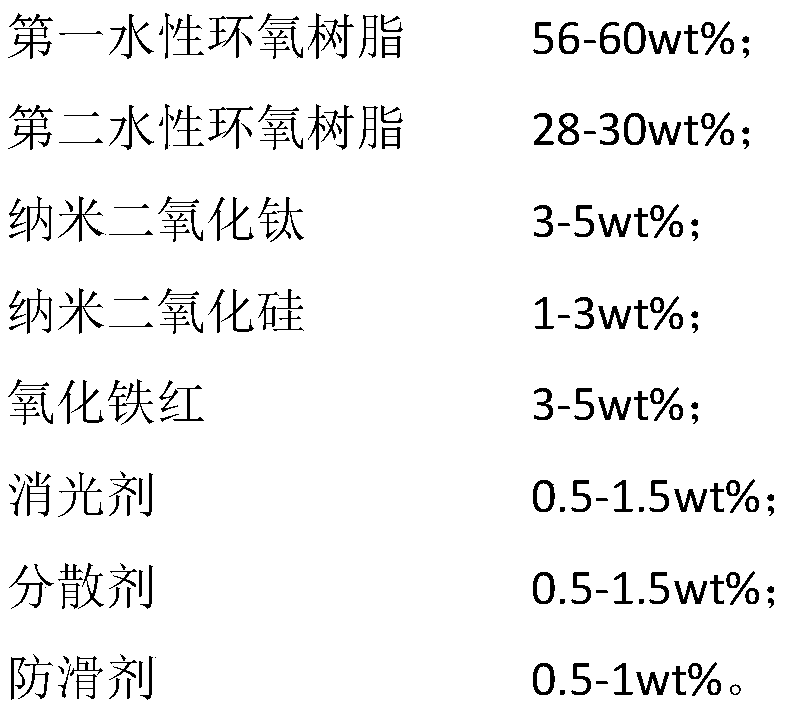

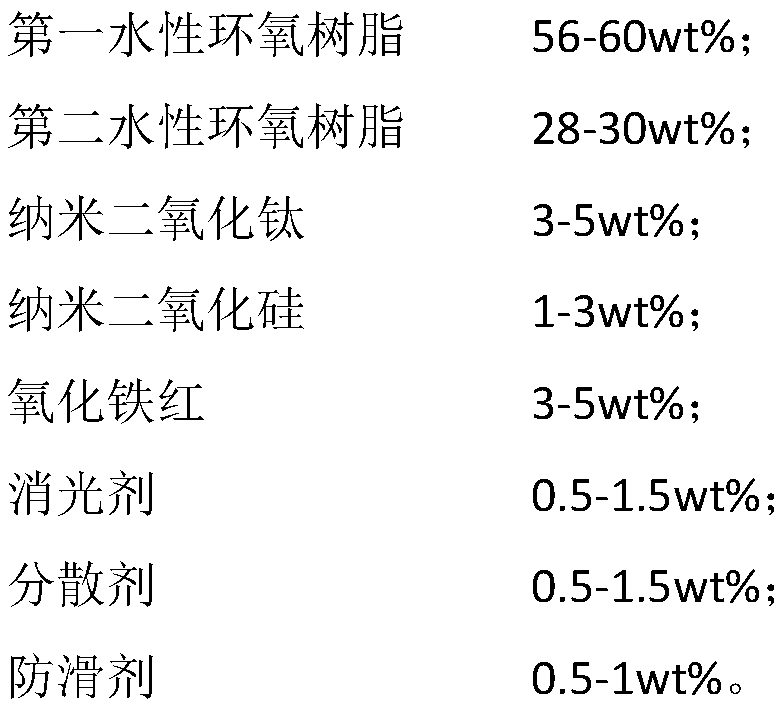

[0076] The asphalt pavement heat reflective coating of the present embodiment comprises the following components:

[0077]

[0078] The preparation method of the asphalt pavement heat reflective coating of the present embodiment comprises the following steps:

[0079] (1), first add 94g of nano-titanium dioxide into 1000g of the first water-based epoxy resin and fully stir for 2min to obtain the first mixture;

[0080] (2), then add 47g of nano silicon dioxide into the first mixture and fully stir for 1min to obtain the second mixture;

[0081] (3), then add 94g of red iron oxide, 35.25g of dispersant and 23.5g of matting agent into the second mixture in sequence and fully stir for 2min to obtain the third mixture;

[0082] (4), finally the second water-based epoxy resin of 500g is added in the third mixture and fully stirred for 2min to obtain a uniformly dispersed water-based epoxy resin coating;

[0083] (5), the water-based epoxy resin coating is evenly brushed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com