Coating hot melt adhesive for hollow glass warm edge strips and manufacturing method of coating hot melt adhesive

A manufacturing method and technology of warm edge strips, applied in the directions of adhesives, adhesive types, grafted polymer adhesives, etc. Excellent bonding performance, good weather resistance and aging resistance, reducing the effect of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0035]

[0036]

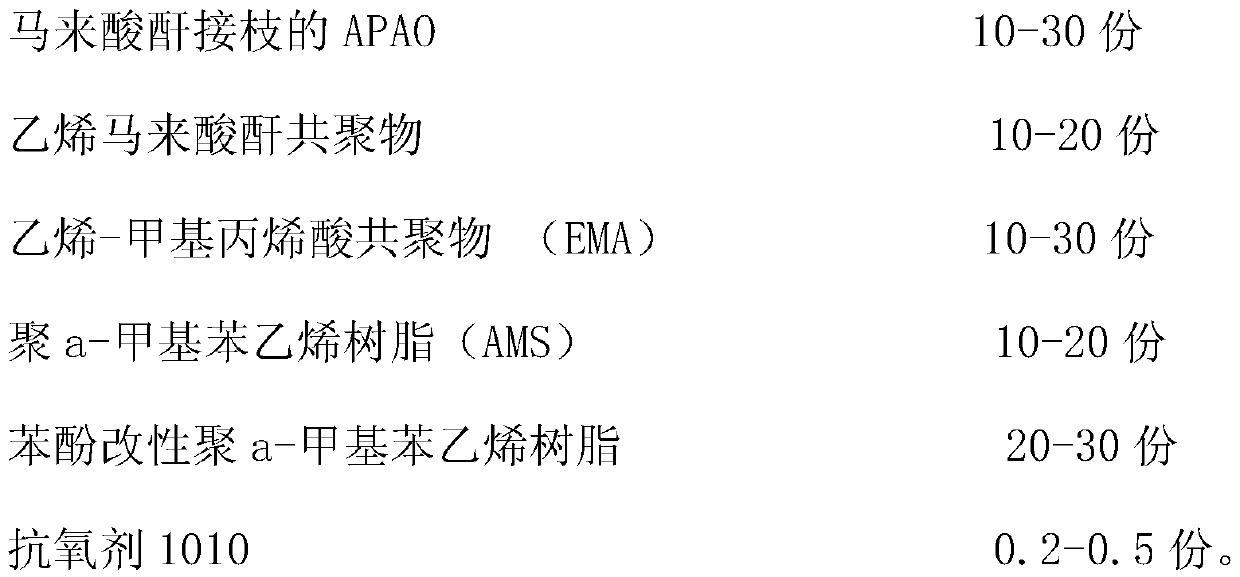

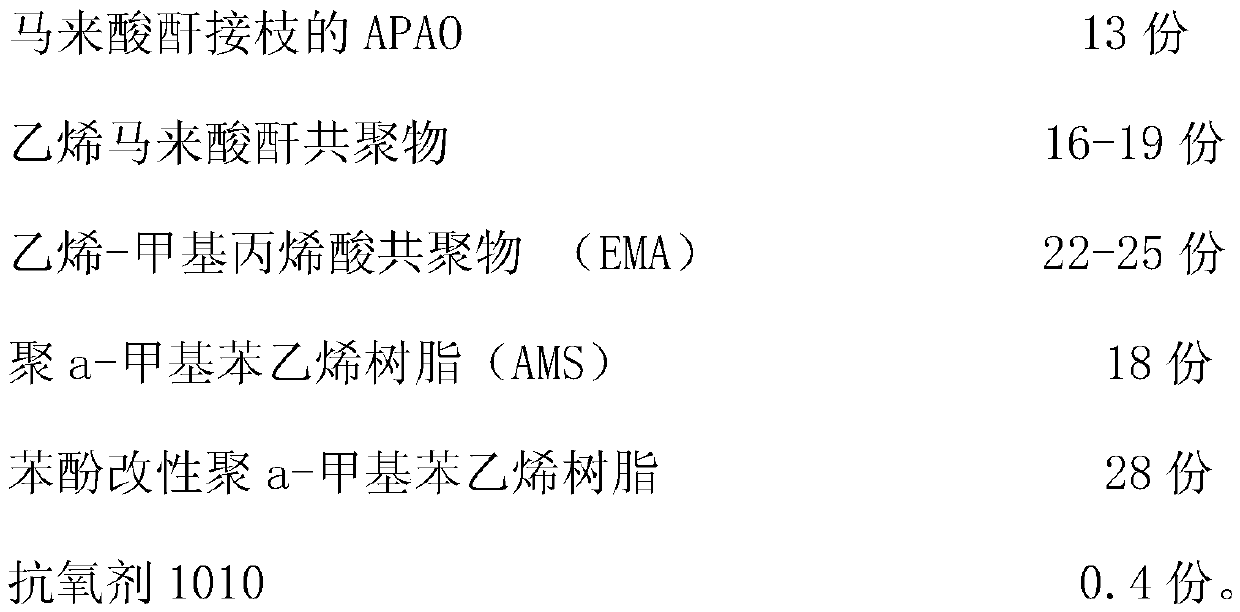

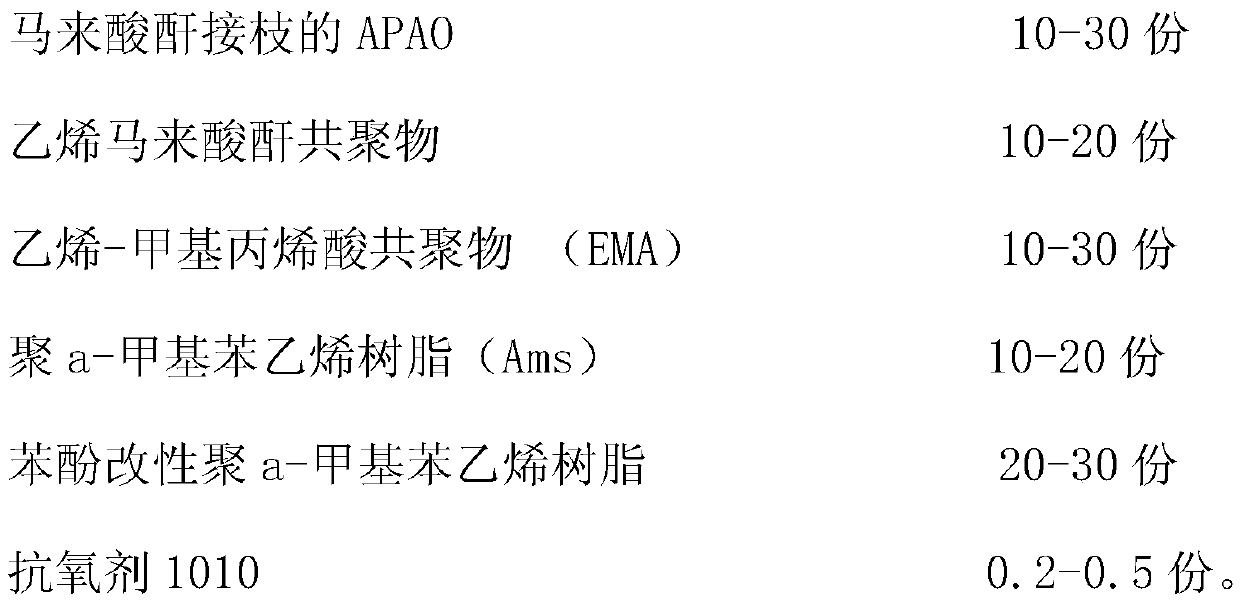

[0037] The data in the table are all parts by weight.

[0038] The manufacturing method of the above-mentioned 5 examples is as follows: the first step is to heat the temperature of the reactor to 170°C-180°C, then add phenol-modified poly-a-methylstyrene resin, ethylene maleic anhydride copolymer, antioxidant Stir with agent 1010 for about 60 minutes; in the second step, reduce the temperature of the reactor to 155°C-160°C, add maleic anhydride grafted APAO and ethylene-methacrylic acid copolymer, stir and melt for about 70 minutes and pump Vacuum, the vacuum gauge pressure is between -0.06mpa and -0.09mpa; in the third step, the temperature of the reactor is kept at 155°C-160°C, adding poly-a-methylstyrene resin (AMS) to stir and vacuumize for 60 minutes, the vacuum gauge pressure Between -0.06mpa and -0.09mpa; after stirring evenly, the outlet is connected to a single-screw extrusion granulation system for underwater pellet cutting, dehydration, dryi...

Embodiment 1

[0041]Example 1: The content of ethylene maleic anhydride copolymer is small, and the peel strength of PP and PVC is acceptable; the curing time just meets the requirements, but affected by the ambient temperature of the workshop, the opening time will not be enough.

Embodiment 2

[0042] Example 2: The content of ethylene-maleic anhydride copolymer increases, and the grafted APAO of maleic anhydride increases; the peel strength of PP increases, the peel strength of PVC decreases, and the viscosity increases, which cannot meet the technical requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com