Treatment process of rust-proof bolt

A treatment process and bolt technology, which is applied in the field of anti-rust bolt treatment process, can solve the problems of easy deterioration and short anti-rust period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

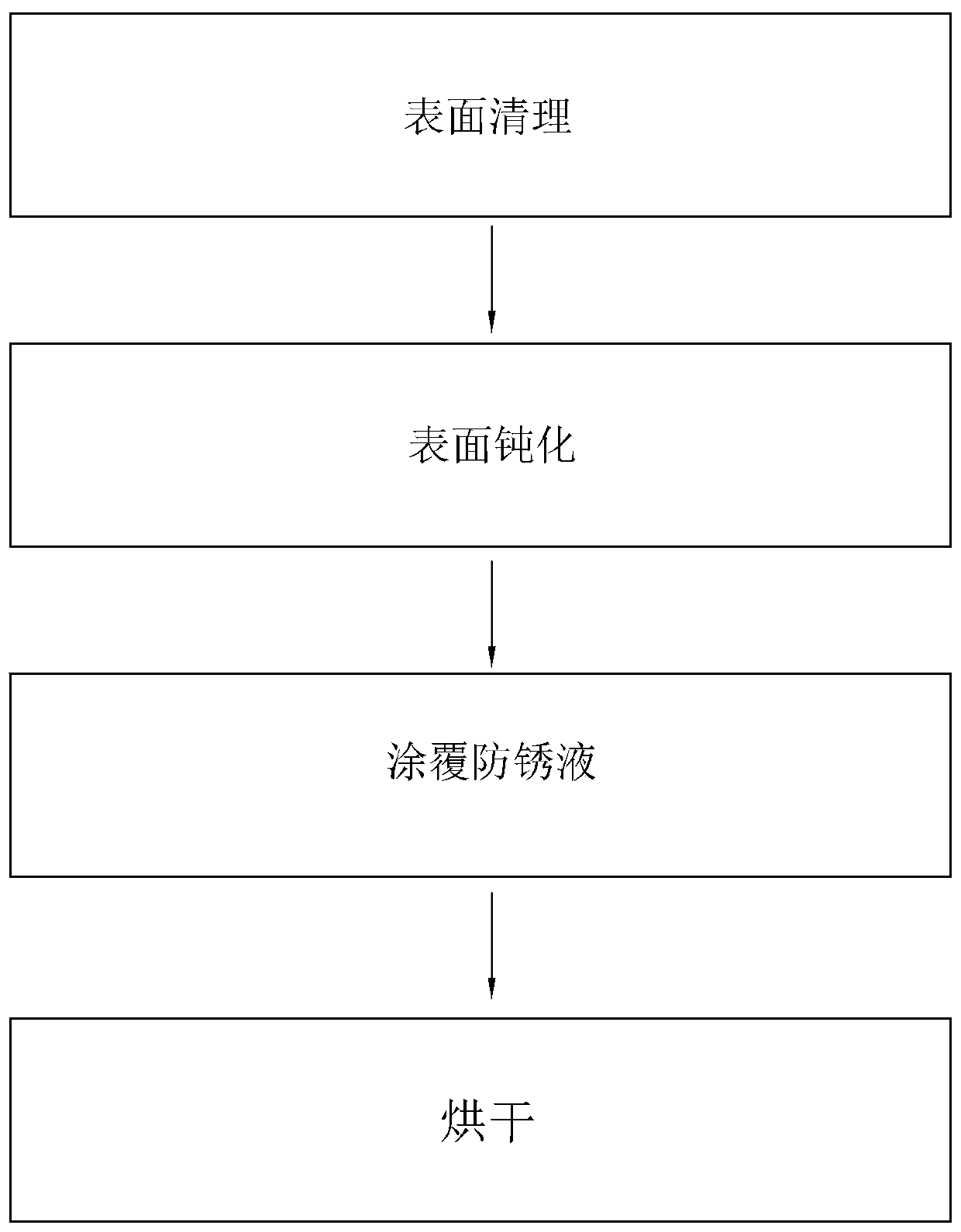

[0044] A treatment process for anti-rust bolts, such as figure 1 shown, including the following steps:

[0045] S1, surface cleaning;

[0046] S2, using a nitrite solution for surface passivation;

[0047] S3, coating anti-rust liquid;

[0048] S4, drying.

[0049] The components of the antirust solution are shown in Table 1 in parts by weight.

Embodiment 2

[0051] The difference from Example 1 is that, in parts by weight, the components of the antirust solution are shown in Table 1.

Embodiment 3

[0053] The difference from Example 1 is that, in parts by weight, the components of the antirust solution are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com