Down feather composite heat insulation material

A technology for down and feathers, applied in the field of down composite thermal insulation materials, can solve the problems of reduced bulkiness and distribution uniformity of down, discount of down jackets in use, and reduced thermal performance, so as to avoid uneven distribution of down, a simple method, and enhanced Warming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

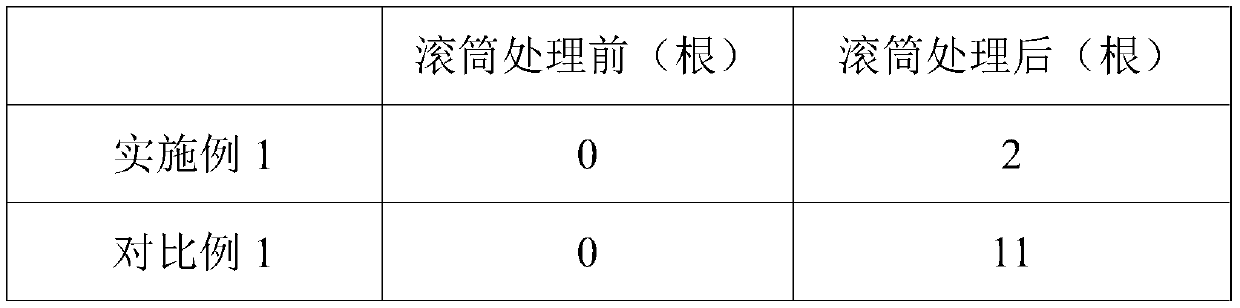

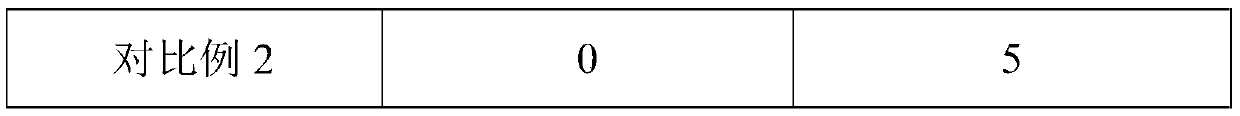

Examples

Embodiment 1

[0023] A kind of down composite thermal insulation material, its preparation method comprises the following steps:

[0024] Step S1: Soak the pinnae in the down feather in a salicylic acid solution at 60-90°C for 0.5-1h, take it out and wash it with clean water for 2-3 times, dry it at 60-80°C before use;

[0025] Step S2: In terms of mass percentage, after grinding 5-10% of the bulking agent into powder, and mixing with 5% of the fiber cotton, the bulking agent is mixed into the fiber cotton to obtain the fiber cotton mixed with the bulking agent;

[0026] Step S3: Add velvet and 5% cotton by mass to the pinnae obtained in step S1, then add the fiber cotton mixed with bulking agent obtained in step S2, and obtain the down composite thermal insulation material after mixing and processing .

[0027] It should be noted that, in terms of mass percentage, the added amount of the down is 80-85%, and the down includes 30% pinnae and 70% down; the bulking agent is a 1:1 mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com