Formula for rapidly lowering uric acid

A uric acid-lowering, formula-based technology, applied in the field of medicine, can solve problems such as inability to prevent gout and high uric acid symptoms, and achieve the effects of clearing inflammatory reactions, repairing damaged cells, and increasing excretion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0023] The weight components of the raw materials of the formula components are as follows: 1-1.5g of Cordyceps militaris extract, 1-2g of fructo-oligosaccharide, 1-1.5g of maltitol, and 0.5-2g of maltodextrin.

[0024] The preparation method is as follows:

[0025] S1: Dry the harvested Cordyceps militaris at low temperature, then pulverize---soak---enzymolysis---homogenize---secondary water extraction-spray drying, to obtain pupae rich in cordycepin and selenium Cordyceps extract;

[0026] S2: Sieve the fructooligosaccharide, maltitol, maltodextrin, and Cordyceps militaris extract respectively, mix them, and set aside;

[0027] S3: sieve the mixture in step 2 again, and then put it into a blender and mix;

[0028] S4: Put the mixture in step 2 into a one-step granulator to carry out the granulation process;

[0029] S5: The mixture is cooled, and the aseptic workshop completes the canning and molding.

specific Embodiment 2

[0031] The weight components of the raw materials of the formula components are as follows: 1.25 g of Cordyceps militaris extract, 1.5 g of fructo-oligosaccharide, 1.25 g of maltitol, and 1 g of maltodextrin.

[0032] The preparation method is as follows:

[0033] S1: Dry the harvested Cordyceps militaris at low temperature, then pulverize---soak---enzymolysis---homogenize---secondary water extraction-spray drying, to obtain pupae rich in cordycepin and selenium Cordyceps extract;

[0034] S2: Sieve the fructooligosaccharide, maltitol, maltodextrin, and Cordyceps militaris extract respectively, mix them, and set aside;

[0035] S3: sieve the mixture in step 2 again, and then put it into a blender and mix;

[0036] S4: Put the mixture in step 2 into a one-step granulator to carry out the granulation process;

[0037] S5: The mixture is cooled, and the aseptic workshop completes the canning and molding.

[0038] In the S2, the mixed sieve has a mesh number of 80 mesh.

[00...

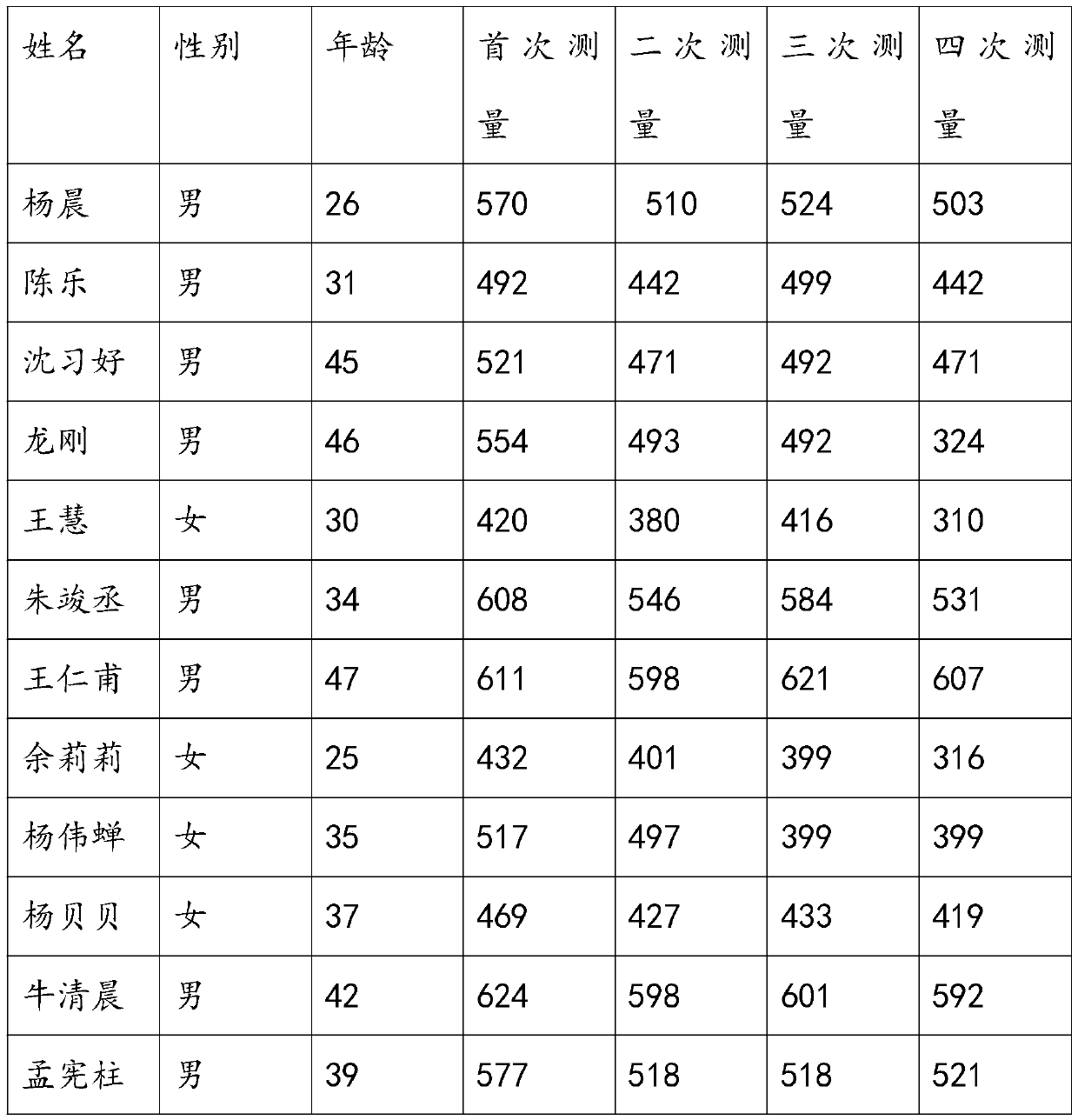

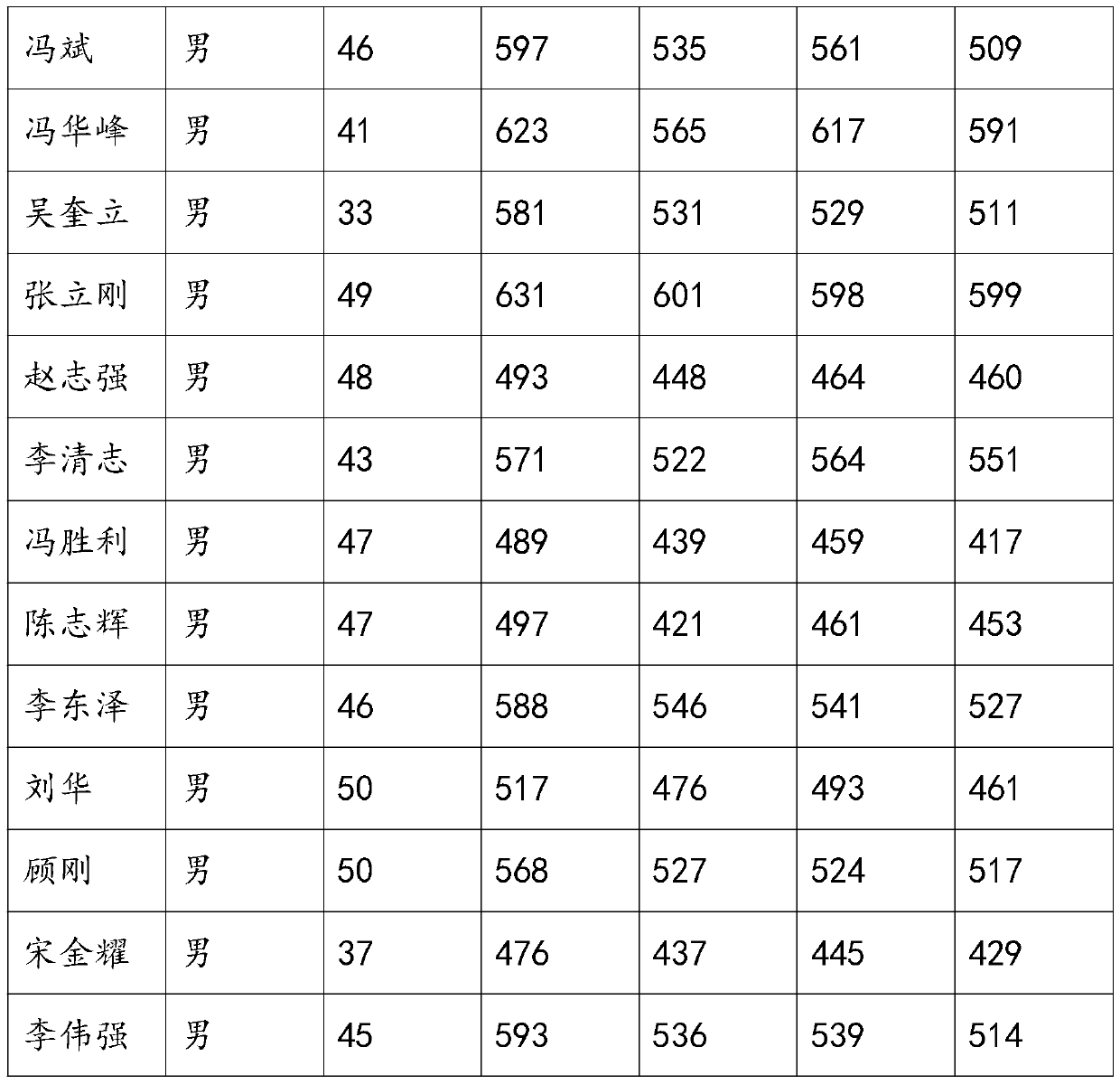

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com