A kind of tea tree organic fertilizer and preparation method thereof

An organic fertilizer and tea tree technology, which is applied in the field of tea tree organic fertilizer and its preparation, can solve the problems of soil nutrient loss, air pollution, and low level of comprehensive utilization, and achieve the goals of avoiding air pollution and soil pollution, being beneficial to environmental protection, and saving resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

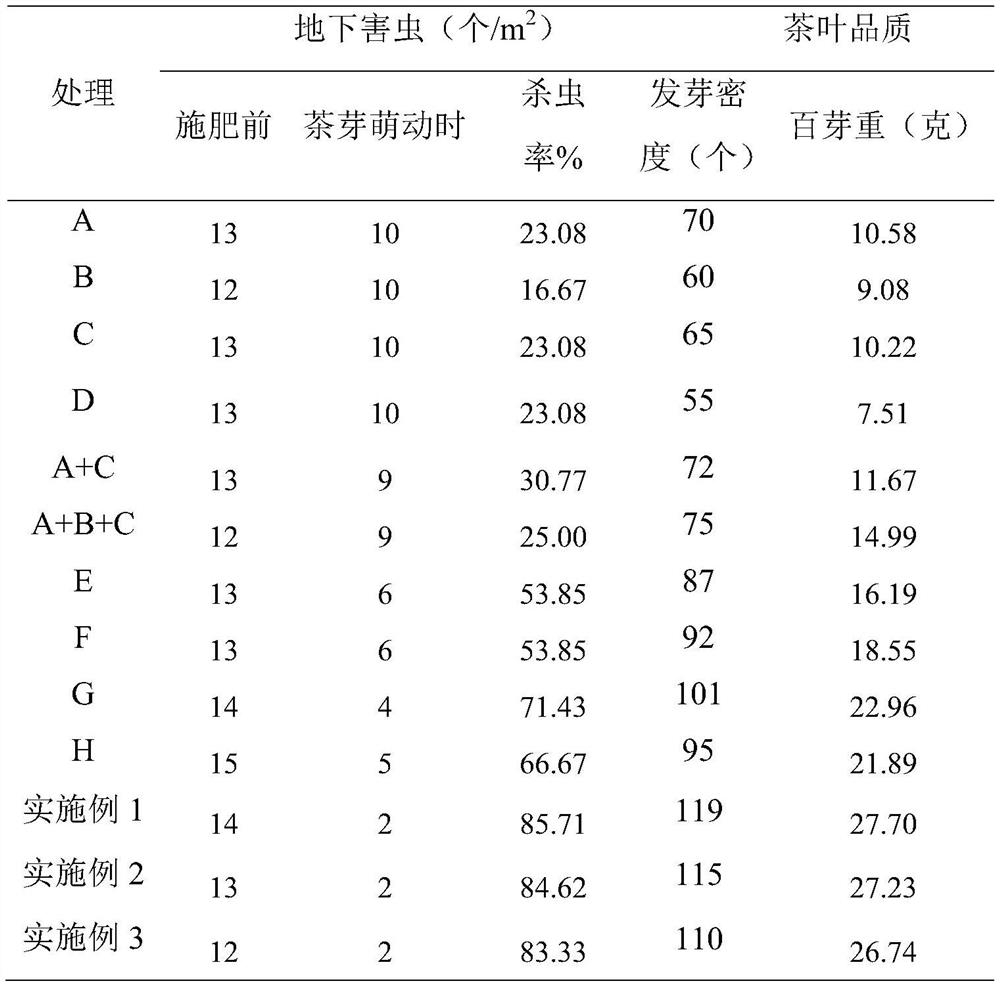

Examples

Embodiment 1

[0040] 400 parts by weight of tea tree by-products, 150 parts by weight of sugarcane waste residue, 100 parts by weight of waste residue of Chinese medicinal materials, 20 parts by weight of fermentation bacteria agent and 300 parts by weight of livestock manure.

[0041] The preparation steps are as follows:

[0042] 1. Cut the branches and leaves trimmed from the tea garden into small sections of 3 to 5 cm, dry and crush them;

[0043] 2. Soak the waste residue of Chinese medicinal materials with lime water for pretreatment, wherein the concentration of lime water is 0.5% (W / V), the ratio of waste residue of Chinese medicinal materials to lime water is 1:8, and the pretreatment time is 12 hours, so that the lime water and Chinese medicinal materials Full contact with waste residue;

[0044] 3. Mix tea tree by-products, sugarcane waste residue, Chinese herbal medicine waste residue and livestock manure, add fermentation bacteria, and stir evenly;

[0045] 4. Add appropriate...

Embodiment 2

[0048] 300 parts by weight of tea tree by-products, 250 parts by weight of sugarcane waste residue, 200 parts by weight of waste residue of Chinese medicinal materials, 25 parts of fermentation bacteria and 400 parts of livestock manure.

[0049] 1. Take the cake after tea seed oil extraction and dry it and crush it;

[0050] 2. Soak the waste residue of Chinese medicinal materials with lime water for pretreatment, wherein the concentration of lime water is 0.5% (W / V), the ratio of waste residue of Chinese medicinal materials to lime water is 1:8, and the pretreatment time is 12 hours, so that the lime water and Chinese medicinal materials Full contact with waste residue;

[0051] 3. Mix tea tree by-products, sugarcane waste residue, Chinese herbal medicine waste residue and livestock manure, add fermentation bacteria, and stir evenly;

[0052] 4. Add appropriate amount of water to adjust the appropriate humidity (60% to 70%) and pH (pH=7.0), make a fermentation stack with a ...

Embodiment 3

[0055] 200 parts by weight of tea tree by-products, 350 parts by weight of sugarcane waste residue, 300 parts by weight of waste residue of Chinese medicinal materials, 30 parts by weight of fermentation bacteria agent and 500 parts by weight of livestock manure.

[0056] 1. Cut the branches and leaves trimmed from the tea garden into small sections of 3 to 5 cm, dry and crush them;

[0057] 2. Soak the waste residue of Chinese medicinal materials with lime water for pretreatment, wherein the concentration of lime water is 0.5% (W / V), the ratio of waste residue of Chinese medicinal materials to lime water is 1:6, and the pretreatment time is 12 hours, so that the lime water and Chinese medicinal materials Full contact with waste residue;

[0058] 3. Mix tea tree by-products, sugarcane waste residue, Chinese herbal medicine waste residue and livestock manure, add fermentation bacteria, and stir evenly;

[0059] 4. Add appropriate amount of water to adjust the appropriate humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com