High-temperature-resistant flexible sensor and preparation method thereof

A flexible sensor, high temperature resistant technology, applied in the field of sensors, can solve the problems of low melting point, flexible sensors have not yet been prepared, and the application of flexible sensors is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

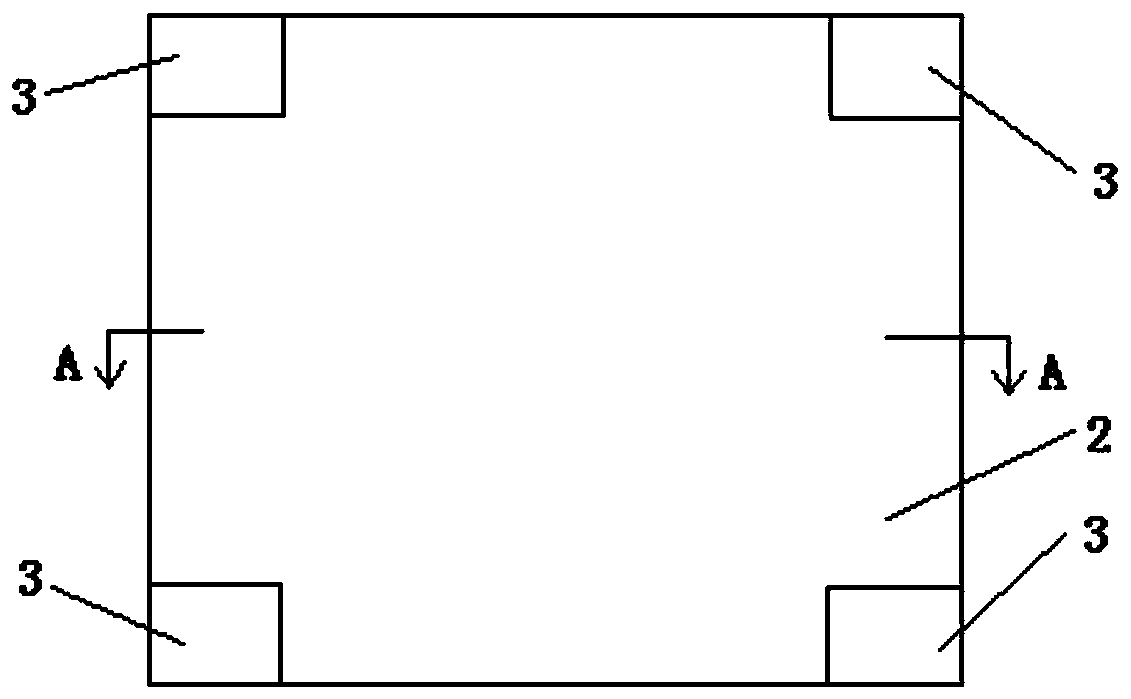

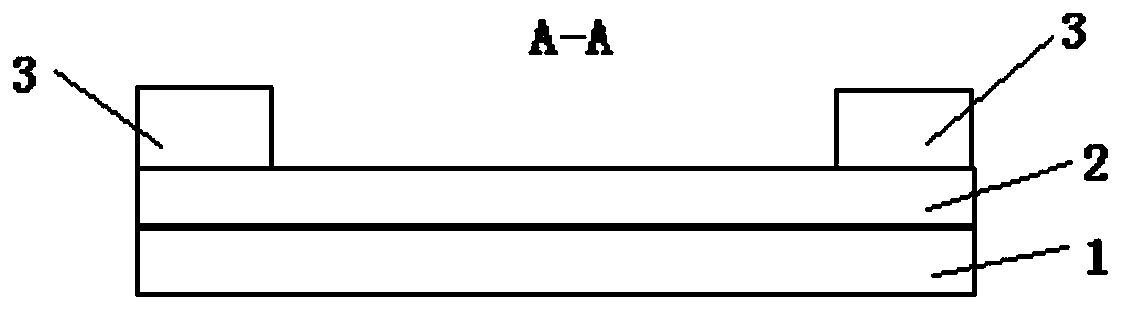

[0045] The preparation method of the high temperature resistant flexible sensor of the present invention mainly comprises the following steps:

[0046] S1: Preparation of mica substrate.

[0047] Preferably, the specific preparation steps of the mica substrate are as follows: first cut the mica sheet into a mica sheet with a thickness of about 0.2-0.5 mm; then stick the mica sheet on the tape, and then slowly bend the tape so that the bottom layer A layer of mica is separated from the mica flakes; this step is repeated until the thickness of the mica flakes reaches 10-100 μm.

[0048] Preferably, the mica sheet is a rectangular sheet material purchased commercially; the adhesive tape is a double-sided polyimide high-temperature adhesive tape; the width of the adhesive tape is the same as that of the mica sheet.

[0049] S2: preparing a conductive layer on the surface of the mica substrate.

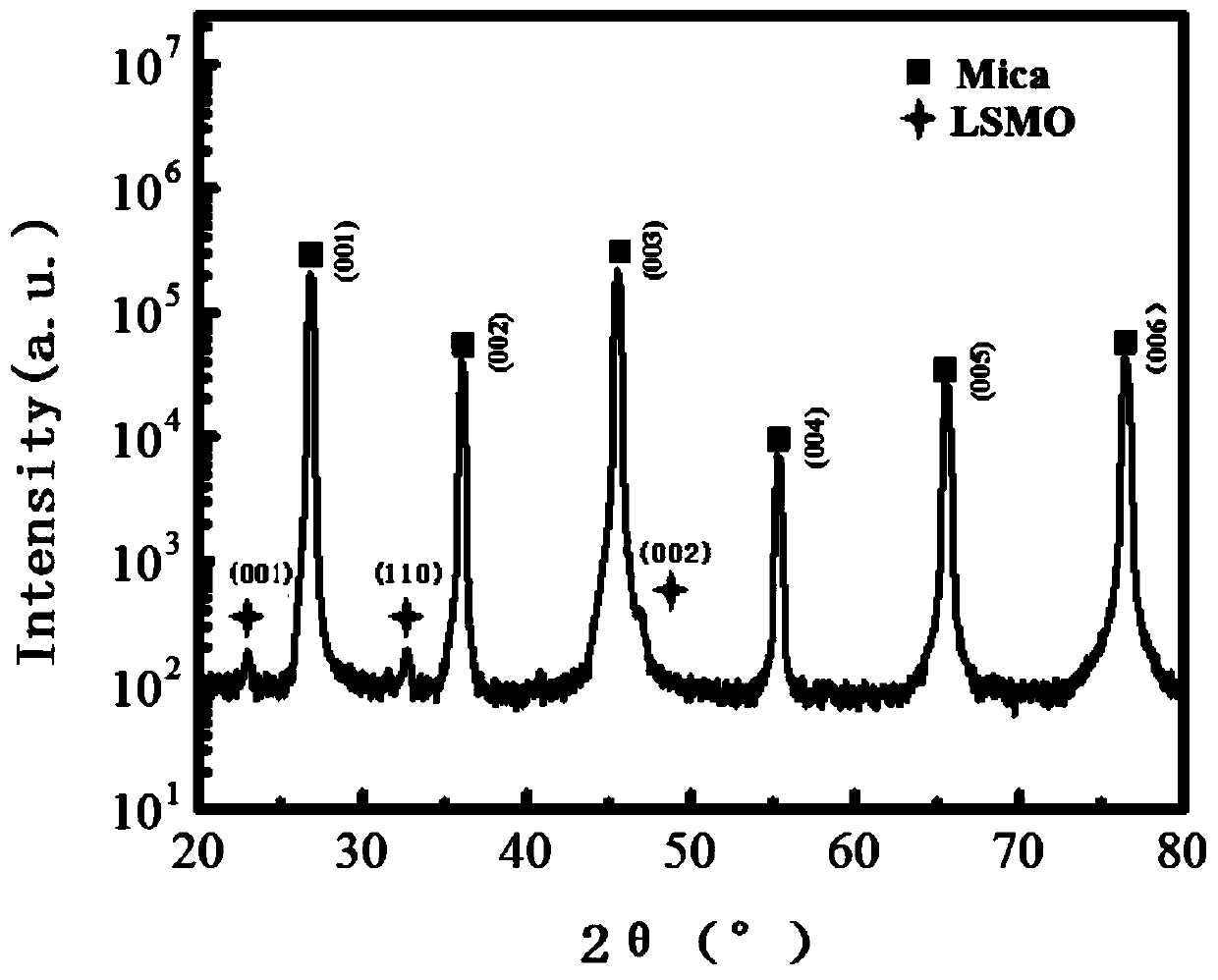

[0050] Preferably, the conductive layer is La 0.7 Sr 0.3 MnO 3 film. The La 0.7...

Embodiment 1

[0059] The preparation method of the high temperature resistant flexible sensor of the present invention is as follows: preparing a mica substrate, then preparing a conductive layer on the surface of the mica substrate, and finally forming a metal electrode on the conductive layer to obtain a high temperature resistant flexible sensor. Specifically include the following steps:

[0060] S1: Preparation of mica substrate:

[0061] First cut the mica sheet into a mica sheet with a thickness of about 0.2-0.5 mm; then stick the mica sheet on a double-sided polyimide high-temperature tape so that the width of the tape is the same as the width of the mica sheet; then Slowly bend the tape to separate the bottom layer of mica from the mica flakes; repeat this step until the thickness of the mica flakes reaches 10 µm.

[0062] S2: Prepare a conductive layer on the surface of the mica substrate:

[0063] By pulsed laser deposition method, the laser is placed on the La 0.7 Sr 0.3 MnO ...

Embodiment 2

[0067]The preparation steps of the high-temperature-resistant flexible sensor of this embodiment 2 are the same as those of the embodiment 1, and the difference lies in the different condition parameters in the preparation process.

[0068] S1: Preparation of mica substrate:

[0069] First cut the mica sheet into a mica sheet with a thickness of about 0.2-0.5 mm; then stick the mica sheet on a double-sided polyimide high-temperature tape so that the width of the tape is the same as the width of the mica sheet; then Slowly bend the tape to separate the bottom layer of mica from the mica flakes; repeat this step until the thickness of the mica flakes reaches 50 µm.

[0070] S2: Prepare a conductive layer on the surface of the mica substrate:

[0071] By pulsed laser deposition method, the laser is placed on the La 0.7 Sr 0.3 MnO 3 target surface, La 0.7 Sr 0.3 MnO 3 The surface of the target is instantly melted into La 0.7 Sr 0.3 MnO 3 Plasma, and deposited on the mica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com