A titanium-based amorphous metal glass dental implant and its preparation method

A dental implant and amorphous metal technology, which is applied in the field of titanium-based amorphous metal glass dental implant and its preparation, can solve the problems of no antibacterial property, serious infection, inflammation around the implant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

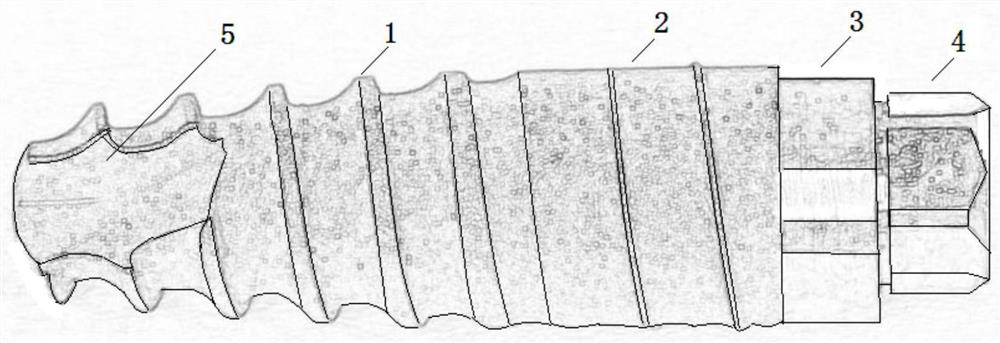

[0031] A titanium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 30 parts of titanium, 2 parts of zirconium, 2 parts of copper, 3 parts of silicon, 2 parts of iron, 2 parts of zinc and 1 part of silver , 1 part of palladium, the diameter of the dental implant is 2mm, and the length is 4mm; the part of the dental implant located in the bone has a self-tapping thread structure with a pitch of 0.7mm and a thread depth of 0.3mm, and the thread section is triangular;

Embodiment 2

[0033] A titanium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 50 parts of titanium, 25 parts of zirconium, 45 parts of copper, 20 parts of silicon, 10 parts of iron, 10 parts of zinc and 5 parts of silver , 15 parts of palladium, the diameter of the dental implant is 6mm, and the length is 13mm; the part of the dental implant located in the bone has a self-tapping thread structure with a pitch of 2mm and a thread depth of 0.6mm, and the thread section is triangular;

Embodiment 3

[0035] A titanium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 75 parts of titanium, 12 parts of zirconium, 25 parts of copper, 10 parts of silicon, 0-10 parts of iron, 5 parts of zinc and silver 3 parts, 7 parts of palladium, the diameter of the dental implant is 4mm, and the length is 7mm; the part of the dental implant located in the bone has a self-tapping thread structure, the pitch is 1.5mm, the thread depth is 0.45mm, and the thread section is triangular;

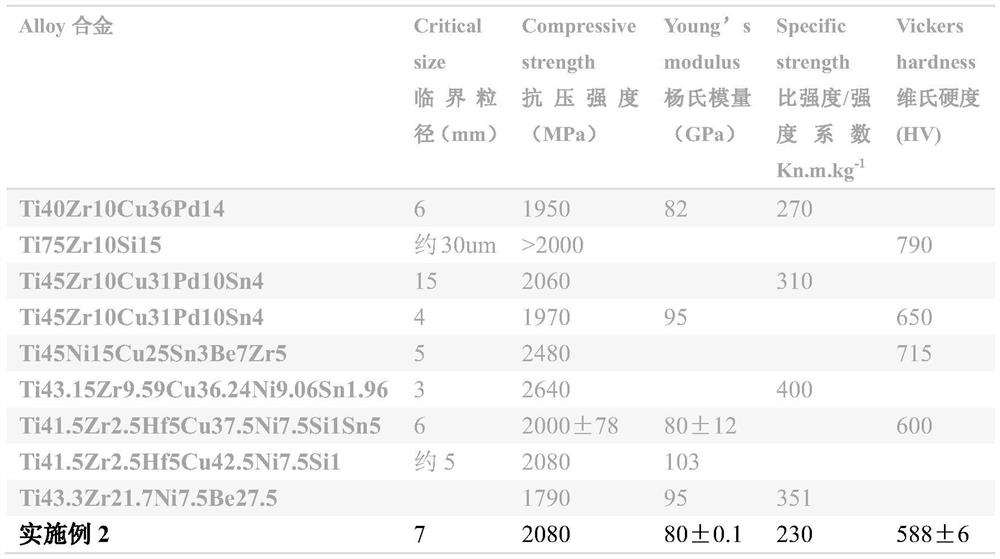

[0036] Embodiment 2 is through mechanical property test, and effect is as follows:

[0037] Summary of mechanical properties of different titanium-based amorphous alloys

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com