Zirconium-based amorphous metallic glass dental implant and preparation method thereof

A dental implant and metallic glass technology, which is applied in dentistry, prostheses, dental implants, etc., can solve the problem of not reducing the three-dimensional bone requirement around the implant area, reducing the attack rate of peri-implantitis, and not improving the quality of implants. Stress distribution and other issues can be reduced to reduce the amount of clinical bone graft, which is conducive to long-term success and moderate elastic modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

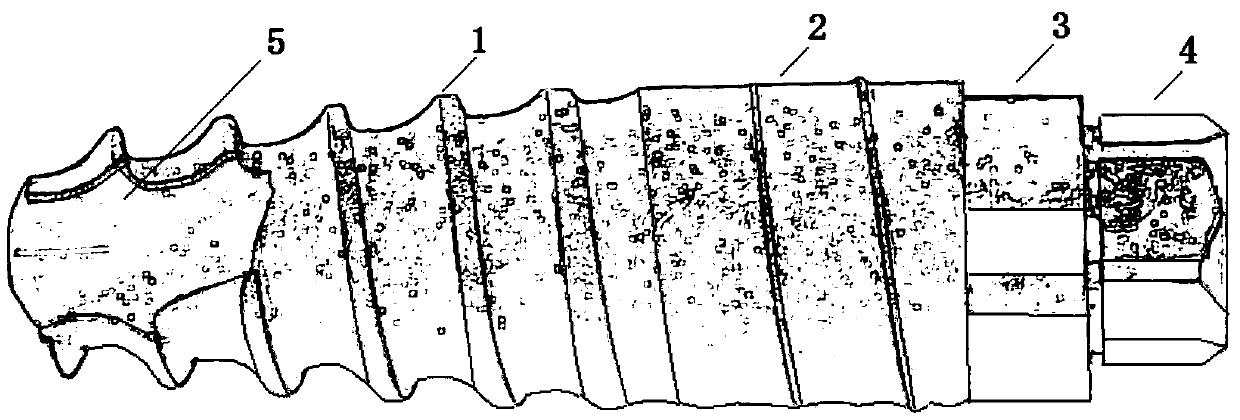

[0036] A zirconium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 30 parts of zirconium, 5 parts of titanium, 5 parts of copper, 5 parts of aluminum, 5 parts of silicon, 2 parts of iron, and 2 parts of zinc 1 part, silver, 1 part, palladium 1 part, the diameter of the dental implant is 2mm, and the length is 4mm; the part of the dental implant located in the bone has a self-tapping thread structure, the pitch is 0.7mm, and the thread depth is 0.3mm. is a triangle;

[0037] Specific process steps:

[0038] 1) Mix the above components, and melt at a temperature of 800 degrees Celsius; vacuum degree: 6.6×10Pa, and cool the melted metal liquid phase at a cooling rate of 10k / s-300k / s to obtain an amorphous metallic glass;

[0039] 2) Process it into a cylindrical rod shape with a diameter of 2-6mm by copper mold casting method, die casting method, or CAD / CAM digital design and processing method;

[0040...

Embodiment 2

[0043] A zirconium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 65 parts of zirconium, 25 parts of titanium, 45 parts of copper, 20 parts of aluminum, 20 parts of silicon, 10 parts of iron, and 10 parts of zinc 5 parts of silver, 5 parts of palladium, the diameter of the dental implant is 6mm, and the length is 13mm; the part of the dental implant located in the bone has a self-tapping thread structure, the pitch is 2mm, and the thread depth is 0.6mm. The thread section is triangular ;

[0044] Specific process steps:

[0045] 1) Mix the above components, and melt at a temperature of 1200 degrees Celsius; vacuum degree: 6.6×6Pa, and cool the melted metal liquid phase at a cooling rate of 10k / s-300k / s to obtain an amorphous metallic glass;

[0046] 2) Process it into a cylindrical rod shape with a diameter of 2-6mm by copper mold casting method, die casting method, or CAD / CAM digital design and pro...

Embodiment 3

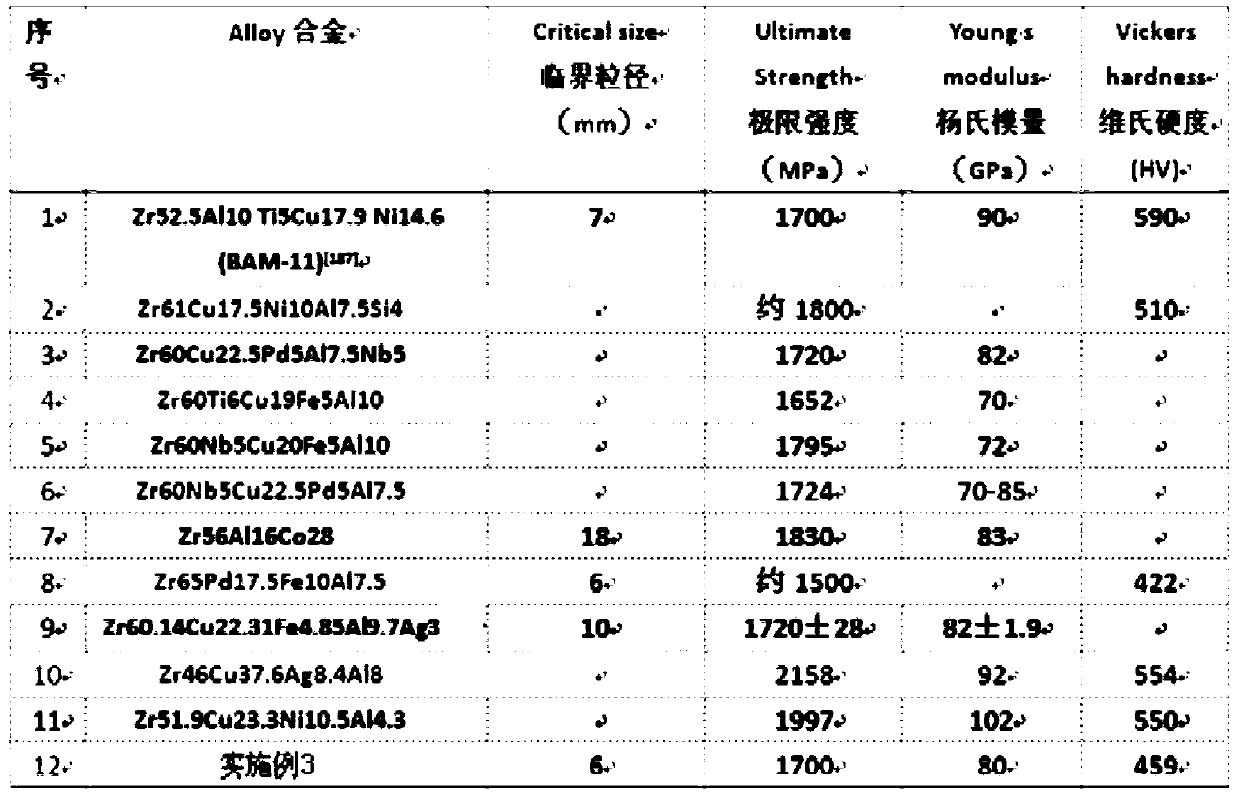

[0050] A zirconium-based amorphous metal glass dental implant of the present invention and its preparation method, in parts by weight, include: 45 parts of zirconium, 15 parts of titanium, 20 parts of copper, 10 parts of aluminum, 10 parts of silicon, 5 parts of iron, and 5 parts of zinc Parts, silver, 3 parts, palladium 3 parts, the diameter of the dental implant is 4mm, and the length is 7mm; the part of the dental implant located in the bone has a self-tapping thread structure, the pitch is 1.5mm, and the thread depth is 0.45mm. is a triangle;

[0051] Specific process steps:

[0052] 1) Mix the above components, and melt at a temperature of 1800 degrees Celsius; vacuum degree: 6.6×3Pa, and cool the melted metal liquid phase at a cooling rate of 10k / s-300k / s to obtain an amorphous metallic glass;

[0053] 2) Process it into a cylindrical rod shape with a diameter of 2-6mm by copper mold casting method, die casting method, or CAD / CAM digital design and processing method;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com